Low-permeability TPU film for automobile headrest and preparation method of low-permeability TPU film

A technology for automobile headrests and films, which is applied in the field of low-permeability TPU films for automobile headrests and its preparation. It can solve the problems of increasing the hydrophobicity of TPU films, the barrier effect of water vapor and oxygen, poor barrier properties of TPU films, and the decline of mechanical properties of TPU films. problems, to achieve good mechanical properties, low water vapor transmission rate, and reduce the transmission rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] This embodiment provides a low-permeability TPU film for automobile headrests, including a laminated TPU film layer and a water vapor barrier layer; the thickness of the TPU film layer is 500 μm, and the thickness of the water vapor barrier layer is 30 μm.

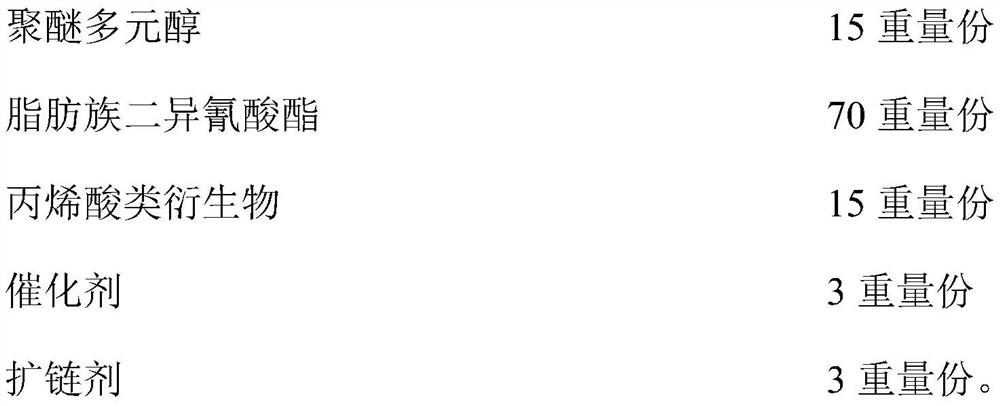

[0052] Wherein, the TPU film layer comprises the following components by weight:

[0053]

[0054] Wherein, the data molecular weight of polyether polyol is 2000, and polyether polyol is the combination of polyoxypropylene diol (Jiangsu Sanmu Chemical Industry, N210) and polytetrahydrofuran diol (German BASF, Poly THF 2000), polyoxypropylene diol and The mass ratio of polytetrahydrofuran diol is 3:1; Aliphatic diisocyanate is isophorone diisocyanate (German Evonik Vestanat IPDI) and cyclohexane dimethylene diisocyanate (Japan Mitsui Takeda Chemical Co., Ltd., Takenate600) The combination, the mass ratio of isophorone diisocyanate and cyclohexane dimethylene diisocyanate is 8:1; Acrylic acid derivative is hydroxye...

Embodiment 2

[0060] This embodiment provides a low-permeability TPU film for automobile headrests, including a laminated TPU film layer and a water vapor barrier layer; the thickness of the TPU film layer is 1000 μm, and the thickness of the water vapor barrier layer is 40 μm.

[0061] Wherein, the TPU film layer comprises the following components by weight:

[0062]

[0063] Wherein, the data molecular weight of polyether polyol is 1000, and polyether polyol is the combination of polyoxypropylene diol (Jiangsu Sanmu Chemical Industry, N210) and polytetrahydrofuran diol (German BASF, Poly THF 2000), polyoxypropylene diol and The mass ratio of polytetrahydrofuran diol is 2:1; Aliphatic diisocyanate is isophorone diisocyanate (German Evonik Vestanat IPDI) and cyclohexane dimethylene diisocyanate (Japan Mitsui Takeda Chemical Co., Ltd., Takenate600) The combination, the mass ratio of isophorone diisocyanate and cyclohexane dimethylene diisocyanate is 10:1; Acrylic acid derivative is hydrox...

Embodiment 3

[0069] This embodiment provides a low-permeability TPU film for automobile headrests, including a laminated TPU film layer and a water vapor barrier layer; the thickness of the TPU film layer is 100 μm, and the thickness of the water vapor barrier layer is 10 μm.

[0070] Wherein, the TPU film layer comprises the following components by weight:

[0071]

[0072] Wherein, the data molecular weight of polyether polyol is 3000, and polyether polyol is the combination of polyoxypropylene diol (Jiangsu Sanmu Chemical Industry, N210) and polytetrahydrofuran diol (German BASF, Poly THF 2000), polyoxypropylene diol and The mass ratio of polytetrahydrofuran diol is 5:1; Aliphatic diisocyanate is isophorone diisocyanate (German Evonik Vestanat IPDI) and cyclohexane dimethylene diisocyanate (Japan Mitsui Takeda Chemical Co., Ltd., Takenate600) The combination, the mass ratio of isophorone diisocyanate and cyclohexane dimethylene diisocyanate is 5:1; The acrylic acid derivative is hydr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com