Marine port engineering concrete anti-corrosive paint

A technology for anti-corrosion coatings and concrete, applied in anti-corrosion coatings, polyamide coatings, epoxy resin coatings, etc., can solve the problems of poor outdoor weather resistance of coatings, easy loss of light and powder, easy degradation and broken chains, etc., to achieve hiding power Strong, guaranteed effectiveness, and increased range of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

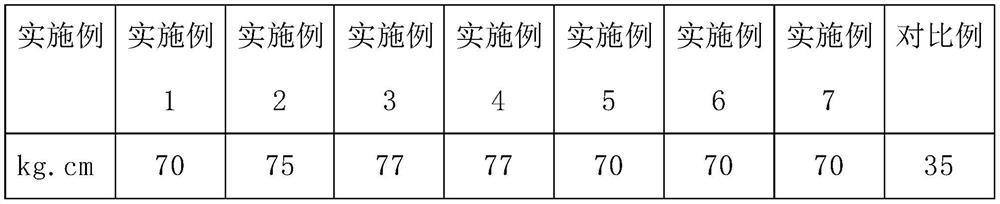

Embodiment 1

[0020] First prepare the bulking agent:

[0021] Add aluminum silicate, aluminum chloride and calcium sulfate to a grinder at a mass ratio of 3:5:2 for mixed grinding, and grind to obtain expansion agent powder, the particle size of which is 50 mesh.

[0022] Then prepare the marine port engineering concrete anticorrosion coating:

[0023] 1) Add 70 parts of epoxy resin and 7 parts of polysiloxane according to the corresponding parts by weight into the high-speed disperser for high-speed stirring, and mix evenly;

[0024] 2) Add the uniformly mixed material in step 1), 5 parts of expansion agent, 12 parts of polyamide curing agent, 16 parts of aluminum powder slurry and 7 parts of ethylene glycol butyl ether acetate film-forming aid into a low-speed mixer for low-speed stirring After mixing evenly, the concrete anti-corrosion coating for marine port engineering is prepared.

Embodiment 2

[0026] First prepare the bulking agent:

[0027] Add aluminum silicate, aluminum chloride and calcium sulfate to a grinder at a mass ratio of 3:5:2 for mixed grinding, and grind to obtain expansion agent powder, the particle size of which is 50 mesh.

[0028] Then prepare the marine port engineering concrete anticorrosion coating:

[0029] 1) Add 72 parts of epoxy resin and 7.2 parts of polysiloxane into the high-speed disperser according to the corresponding parts by weight, stir at high speed, and mix evenly;

[0030] 2) Add the homogeneously mixed materials in step 1), 6 parts of expansion agent, 16 parts of polyamide curing agent, 17 parts of aluminum powder slurry and 7.2 parts of ethylene glycol butyl ether acetate film-forming aid into a low-speed mixer for low-speed stirring After mixing evenly, the concrete anti-corrosion coating for marine port engineering is prepared.

Embodiment 3

[0032] First prepare the bulking agent:

[0033] Add aluminum silicate, aluminum chloride and calcium sulfate to a grinder at a mass ratio of 3:5:2 for mixed grinding, and grind to obtain expansion agent powder, the particle size of which is 60 mesh.

[0034] Then prepare the marine port engineering concrete anticorrosion coating:

[0035] 1) Add 75 parts of epoxy resin and 7.5 parts of polysiloxane according to the corresponding parts by weight into the high-speed disperser for high-speed stirring, and mix evenly;

[0036] 2) Add the uniformly mixed materials in step 1), 8 parts of expansion agent, 20 parts of polyamide curing agent, 17 parts of aluminum powder slurry and 7.5 parts of ethylene glycol butyl ether acetate film-forming aid into a low-speed mixer for low-speed stirring After mixing evenly, the concrete anti-corrosion coating for marine port engineering is prepared.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com