High-entropy alloy reinforced aluminum matrix composite material and preparation method thereof

A technology of high-entropy alloys and composite materials, which is applied in the field of high-entropy alloy-reinforced aluminum-matrix composites and its preparation, and can solve the problem of low hardness and wear resistance of aluminum alloys, affecting the application of aluminum-matrix composites, and poor wettability, etc. problem, to achieve the effect of low production cost, no component segregation, and fine grain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

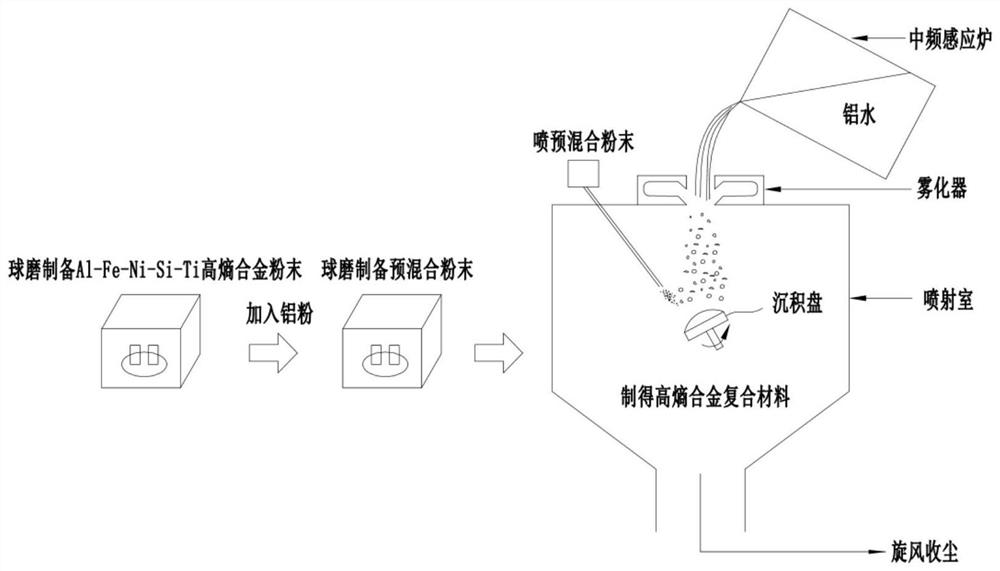

[0028] Such as image 3 As shown, the preparation method of the high-entropy alloy reinforced aluminum matrix composite material of the present invention comprises the following steps:

[0029] S01. Weigh 5mol%-35mol% of Al, 5mol%-35mol% of Fe, 5mol%-35mol% of Ni, 5mol%-35mol% of Si, 5mol%-35mol% of Ti metal powder according to the following molar ratios, The weighed metal powders are mixed to obtain amorphous high-entropy alloy powders. The weighing of each metal powder is carried out in a vacuum glove box, and the particle diameter of each metal powder is 200-300 mesh. The mixing of various metal powders is carried out in a vacuum ball mill tank, the ball milling time is 180-250h, and the ball mill speed is 200-400r / min. Vacuum is extracted from the vacuum ball milling jar and filled with an inert protective gas argon in the vacuum ball milling jar, so that the mixing of each metal powder is carried out under an inert gas atmosphere.

[0030] S02. Mix the high-entropy all...

Embodiment 1

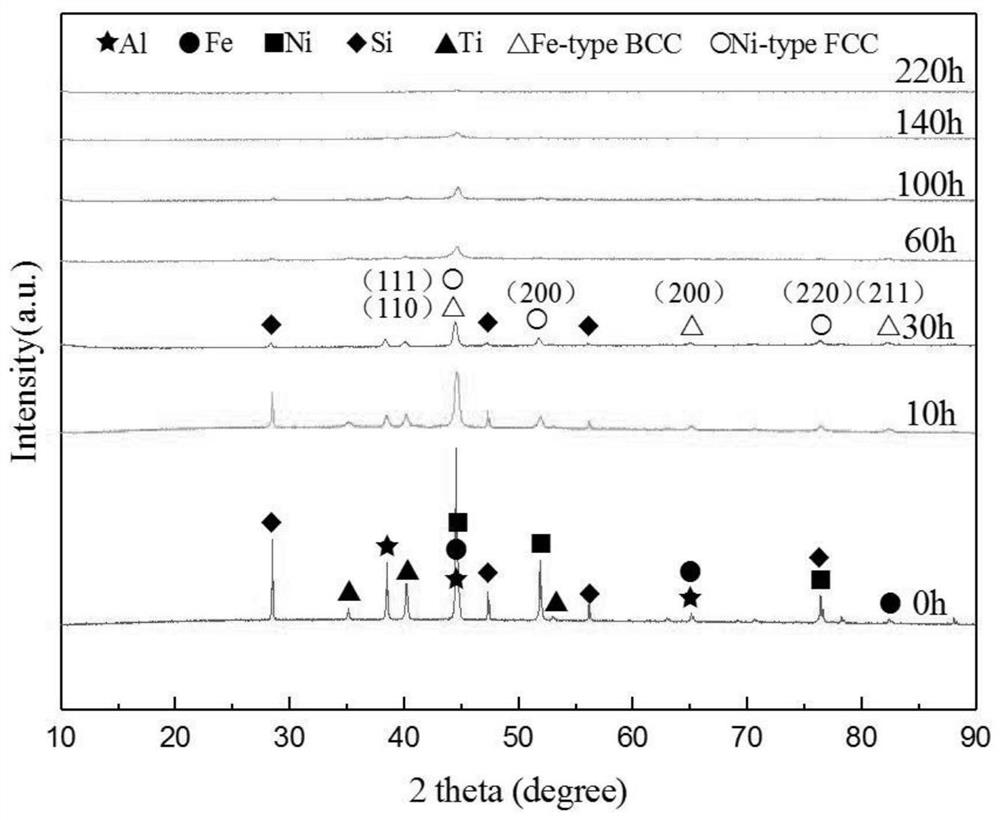

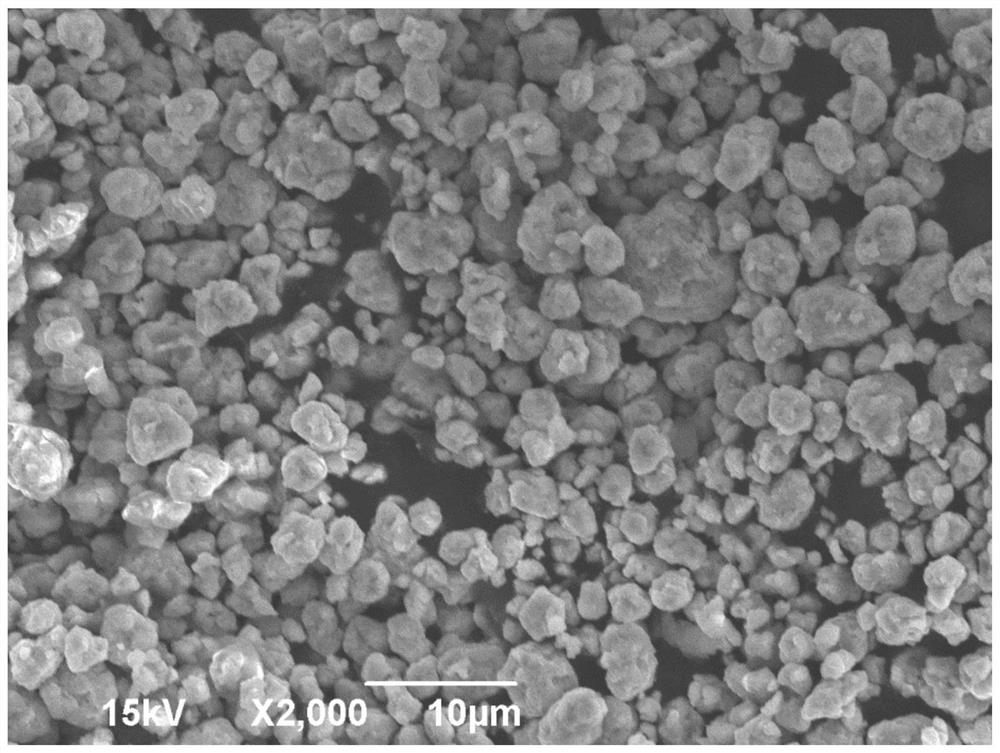

[0035] S01. Preparation of AlFeNiSiTi High Entropy Alloy Powder Ⅰ

[0036] In a vacuum glove box, weigh 20mol% of Al powder, 20mol% of Fe powder, 20mol% of Ni powder, 20mol% of Si powder, and 20mol% of Ti powder. In the stainless steel ball milling tank, add cemented carbide balls, the ball-to-material ratio is 10:1, the weight ratio of large, medium and small balls is 1:2:3, then add n-heptane whose mass is 1% of the total powder mass, and then the ball milling tank is first Vacuum is extracted and then filled with high-purity argon for inert gas protection. On the planetary ball mill, the rotating speed is 300r / min for 220h ball milling. In order to prevent the tank body from overheating due to long-term ball milling, stop the machine for 1 hour every 10 hours of ball milling. After 220 hours of ball milling, the powder is completely alloyed, resulting in AlFeNiSiTi amorphous high-entropy alloy powder. The XRD pattern of the powder is shown in the attached figure 1 As show...

Embodiment 2

[0042] S01. Preparation of AlFeNiSiTi High Entropy Alloy Powder Ⅱ

[0043] Weigh 10mol% Al powder, 25mol% Fe powder, 25mol% Ni powder, 20mol% Si powder, 20mol% Ti powder in a vacuum glove box, the powder particle size is 200 mesh, and the 5 kinds of powders are packed Put it into the stainless steel ball milling tank, add hard alloy balls, the ball-to-material ratio is 10:1, the weight ratio of large, medium and small balls is 1:2:3, then add n-heptane with a quality of 2% of the total powder mass, and then the ball milling tank First extract the vacuum and then fill it with high-purity argon for inert gas protection. On the planetary ball mill, the rotating speed is 400r / min for 200h of ball milling. In order to prevent the tank body from overheating due to long-term ball milling, stop the machine for 1 hour every 20 hours of ball milling.

[0044] S02. Preparation of premixed powder Ⅱ

[0045] Weigh the high-entropy alloy powder and Al powder prepared in S01 according to t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Average hardness | aaaaa | aaaaa |

| Average tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com