Al@(TiB2+Ti4O7)-PbO2 anode plate with core-shell-like structure and preparation method of Al@(TiB2+Ti4O7)-PbO2 anode plate

A technology of core-shell structure and anode plate, which is applied in the direction of electrode, superimposed layer plating, electrolytic inorganic material plating, etc. It can solve the problems of easy peeling and failure of the coating and active catalytic layer, cracking of the electrode interface, and needs to be improved. Improved fluidity and composition uniformity, low cost, and improved spraying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

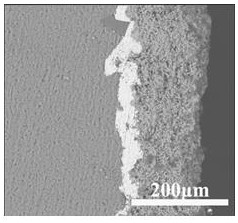

[0033] A kind of core-shell structure Al@(TiB 2 +Ti 4 o 7 )-PbO 2 Anode plate, mainly including Al metal plate support, TiB 2 +Ti 4 o 7 Ceramic interlayer and PbO 2 For the active catalytic layer, the Al metal plate used is 6061 aluminum alloy with a size of 200mm×200mm×6mm. The specific preparation process includes the following steps:

[0034] (1) Grind the surface of the Al metal plate with a wire brush, then ultrasonically clean it in 10wt.% NaOH alkaline solution for 10 minutes, wash the surface with distilled water, and perform sandblasting treatment after drying in a drying oven to obtain a roughened Al surface. Metal plate.

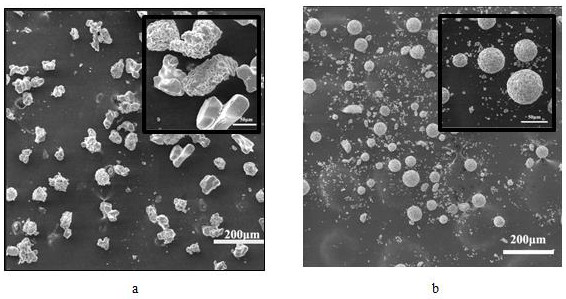

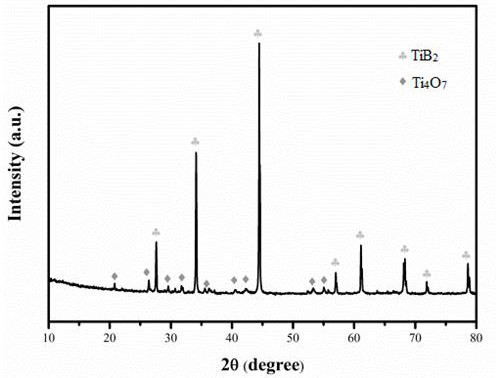

[0035] (2) The spray granulation method is used to agglomerate and sinter TiB 2 +Ti 4 o 7 Mixed powder (90wt.%TiB 2 +10wt.%Ti 4 o 7 ) for spheroidization and granulation treatment. The specific process parameters are: the drying temperature is 180°C, the binder content is 0.6wt.%, the solid phase content is 40wt.%, and the rotation sp...

Embodiment 2

[0039] A kind of core-shell structure Al@(TiB 2 +Ti 4 o 7 )-PbO 2 Anode plate, mainly including Al metal plate support, TiB 2 +Ti 4 o 7 Ceramic interlayer and PbO 2 For the active catalytic layer, the Al metal plate used is 1060 pure aluminum with a size of 200mm×200mm×6mm. The specific preparation process includes the following steps:

[0040] (1) Grind the surface of the Al metal plate with a wire brush, then ultrasonically clean it in 5wt.% NaOH alkaline solution for 20 minutes, wash the surface with distilled water, and perform sandblasting after drying in a drying oven to obtain a roughened Al surface. Metal plate.

[0041] (2) The spray granulation method is used to agglomerate and sinter TiB 2 +Ti 4 o 7 Mixed powder (90wt.%TiB 2 +10wt.%Ti 4 o 7 ) for spheroidization and granulation treatment. The specific process parameters are as follows: the drying temperature is 200°C, the binder content is 1wt.%, the solid phase content is 50wt.%, and the rotation speed...

Embodiment 3

[0045] A kind of core-shell structure Al@(TiB 2 +Ti 4 o 7 )-PbO 2 Anode plate, mainly including Al metal plate support, TiB 2 +Ti 4 o 7 Ceramic interlayer and PbO 2 For the active catalytic layer, the Al metal plate used is 1060 pure aluminum with a size of 200mm×200mm×6mm. The specific preparation process includes the following steps:

[0046] (1) Grind the surface of the Al metal plate with a wire brush, then ultrasonically clean it in 10wt.% NaOH alkaline solution for 15 minutes, wash the surface with distilled water, and perform sandblasting treatment after drying in a drying oven to obtain a roughened Al surface. Metal plate.

[0047] (2) The spray granulation method is used to agglomerate and sinter TiB 2 +Ti 4 o 7 Mixed powder (90wt.%TiB 2 +10wt.%Ti 4 o 7 ) for spheroidization and granulation treatment. The specific process parameters are: the drying temperature is 240°C, the binder content is 1.5wt.%, the solid phase content is 60wt.%, and the rotation spe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com