Shale gas well cementation and oil displacement type flushing agent and preparation method thereof

A technology for shale gas well and flushing agent, which is applied in the field of materials, can solve the problems of not meeting the requirements of cementing quality, affecting the service life of shale gas wells of cement sheath integrity, and reducing the cementing quality of cementing stone.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] A shale gas well cementing oil displacement flushing agent provided in this embodiment is prepared through the following steps:

[0065] Step 1. Add 100 parts of tap water into the reaction kettle, start stirring, heat up to 50°C, add 24 parts of emulsifier (which consists of 19.2 parts of cetearyl polyoxyethylene ether, 4.8 parts of fatty alcohol polyoxyethylene ether phosphate Potassium), so that the emulsifier is fully dissolved;

[0066] Step 2. Add 20 parts of co-emulsifier and stir for 30-50 minutes;

[0067] Step 3. Add 10 parts of hydration inhibitor (consisting of 1 part of polyethylene glycol, 6 parts of glucoside and 3 parts of oleyl alcohol polyoxyethylene ether), stir for 15-30 minutes, and cool to room temperature to obtain the shale Gas well cementing oil displacement flushing agent.

Embodiment 2- Embodiment 24

[0069] The specific components of the emulsifier, co-solvent, and hydration inhibitor in Examples 2-24 were adjusted, as shown in Table 1.

experiment example 1

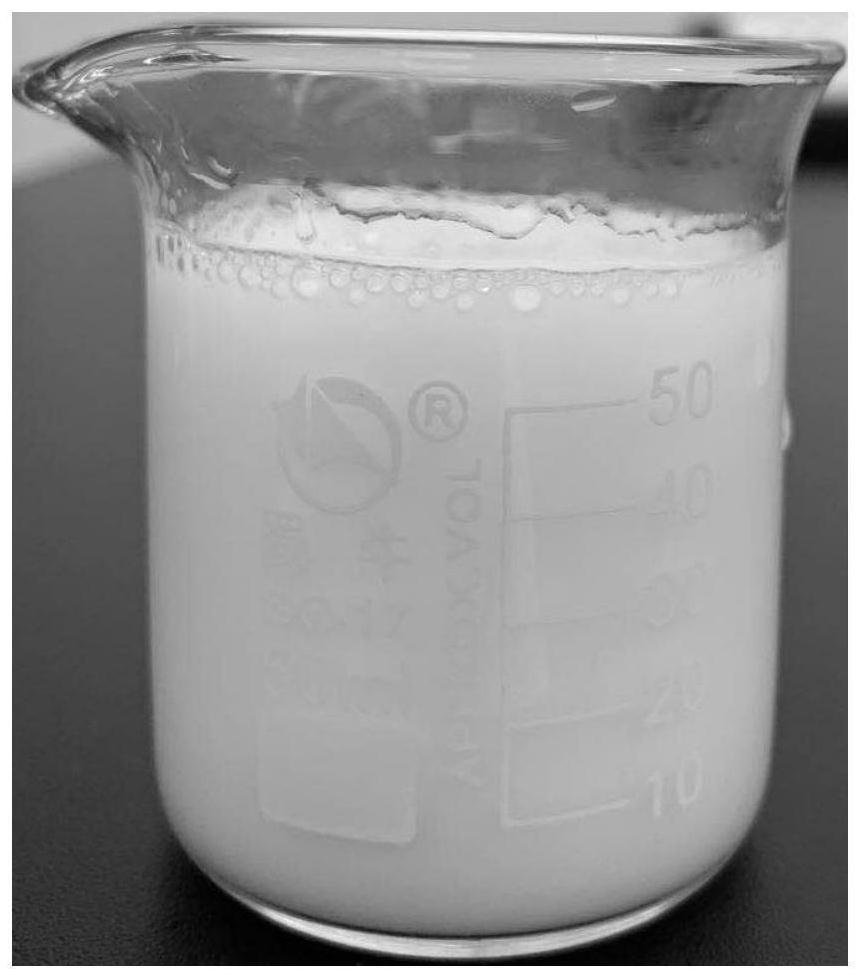

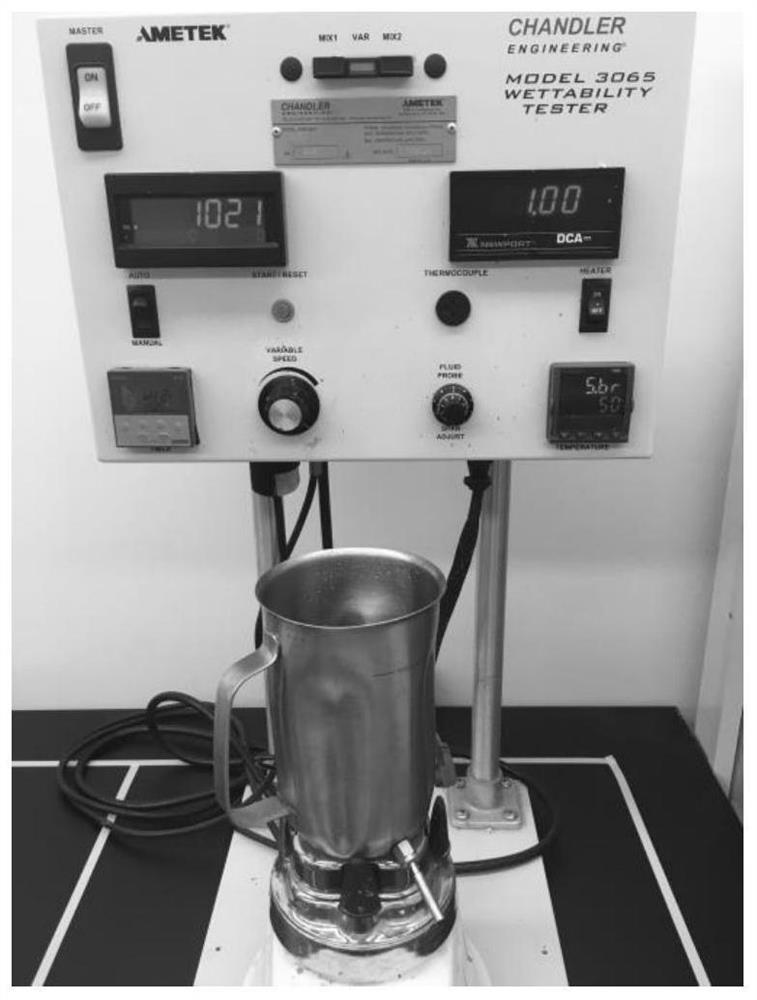

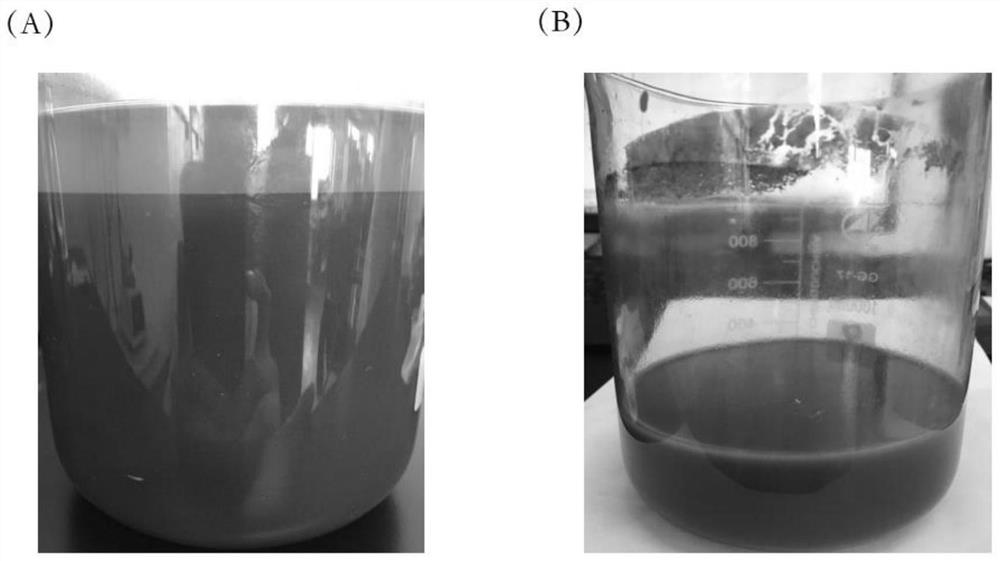

[0098] The emulsifying ability of the flushing agent of each embodiment and comparative example to the base oil of shale gas oil-based drilling fluid is evaluated as follows:

[0099] The shale gas oil-based drilling fluid base oil is 5# white oil, and the flushing agent prepared in each embodiment and each comparative example is diluted with water to a concentration of 15 wt%. Mix 5# white oil with the diluent samples of each embodiment and each comparative example according to the volume ratio: 5:95, 10:90, 20:80, stir and mix at 2000r / min for 30min, observe the mixing state and stability Time, the data are shown in Table 2-Table 4. The emulsification effect of the flushing agent on the base oil is closely related to the oil displacement function of the flushing agent on the oil-based drilling fluid. The emulsification effect can be obtained through the mixing state and stability time.

[0100] Table 2

[0101]

[0102]

[0103] table 3

[0104]

[0105]

[01...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com