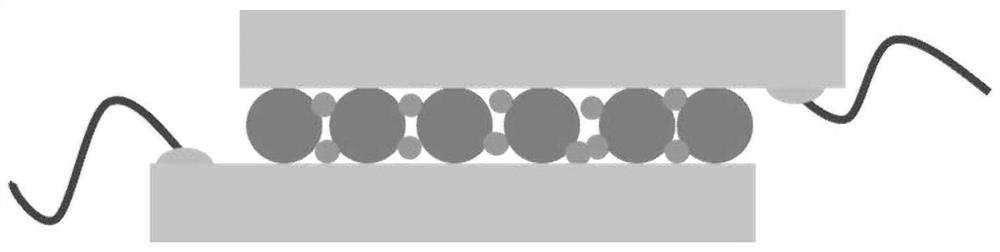

A kind of titanium dioxide/carbon dot composite film pressure sensor and its preparation method

A technology of pressure sensor and titanium dioxide, which is applied in thin film varistors, varistor cores, fluid pressure measurement by changing ohmic resistance, etc., can solve the problems of high production equipment requirements and complicated preparation process, and achieve low cost , simple preparation process and simple sensor structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The invention provides a preparation method of a titanium dioxide / carbon dot composite membrane pressure sensor, comprising the following steps:

[0041] (1) Preparation of porous TiO2 thin film:

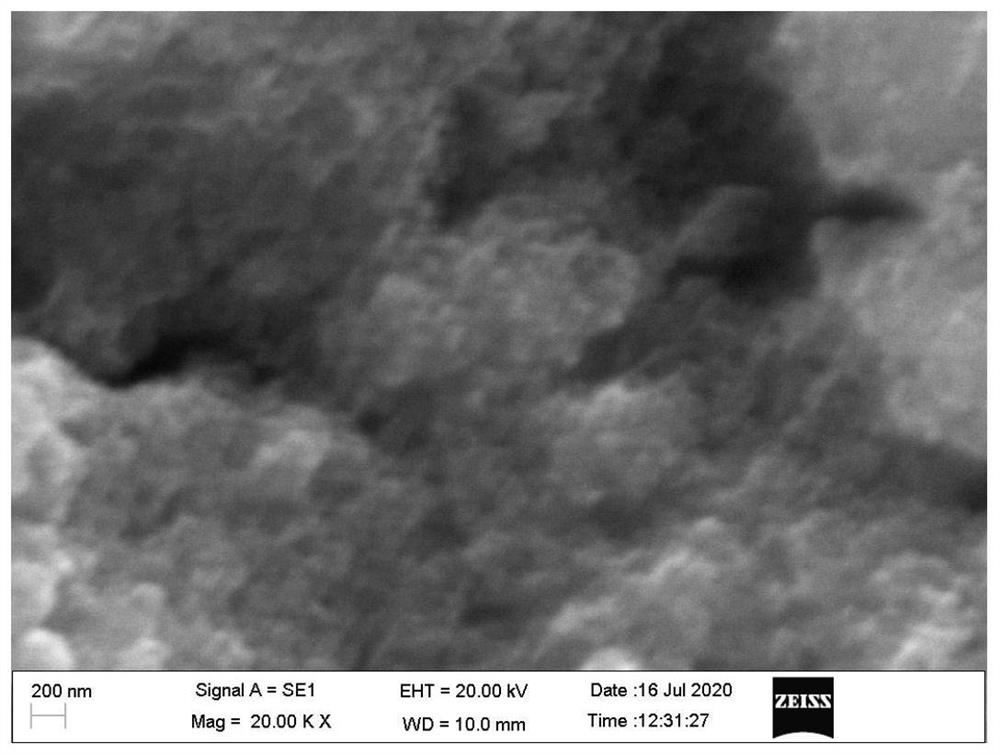

[0042] According to the mass ratio, 60-70% polyethylene glycol 20000 aqueous solution, 20-25% nano-TiO 2 , 0.5-1.5% acetylacetone and 4-8% absolute ethanol were mixed and stirred, ground, added 4-8% polyethylene glycol octyl phenyl ether aqueous solution, and continued to grind until uniform; TiO 2 slurry; the TiO 2 The slurry is coated on the surface of FTO; it is kept warm for a period of time, and then put into a resistance furnace for sintering to obtain porous TiO 2 film.

[0043] Among them, the concentration of polyethylene glycol 20000 aqueous solution is 10-20g / mL, and the concentration of polyethylene glycol octylphenyl ether aqueous solution is 5-15g / mL; the raw materials are mixed and stirred, and magnetic stirring and ultrasonic stirring are used to alternatel...

Embodiment 1

[0055] (1) Porous TiO 2 Film preparation: Weigh PEG-20000, add it into 10ml ultrapure water, and stir it magnetically to dissolve it; for PEG-20000 aqueous solution with a concentration of 10g / mL, take 65% PEG-20000 aqueous solution, and then add 25% nano-TiO 2 (P25), 0.5% acetylacetone and 5% dehydrated alcohol, magnetic stirring and ultrasonic stirring are alternately processed 6 times; after pouring into a mortar and grinding, adding 4.5% concentration is 10Vol.% Triton X100 aqueous solution, and continue grinding until Uniform; FTO is arranged in a vertical column, and TiO 2 The slurry is coated on the surface of the FTO; placed at room temperature for a period of time, kept at 60°C for 30 minutes, and then placed in a resistance furnace for sintering. The sintering temperature in the resistance furnace was uniformly raised from room temperature to 450°C at 4°C / min, and kept at this temperature for 30 minutes.

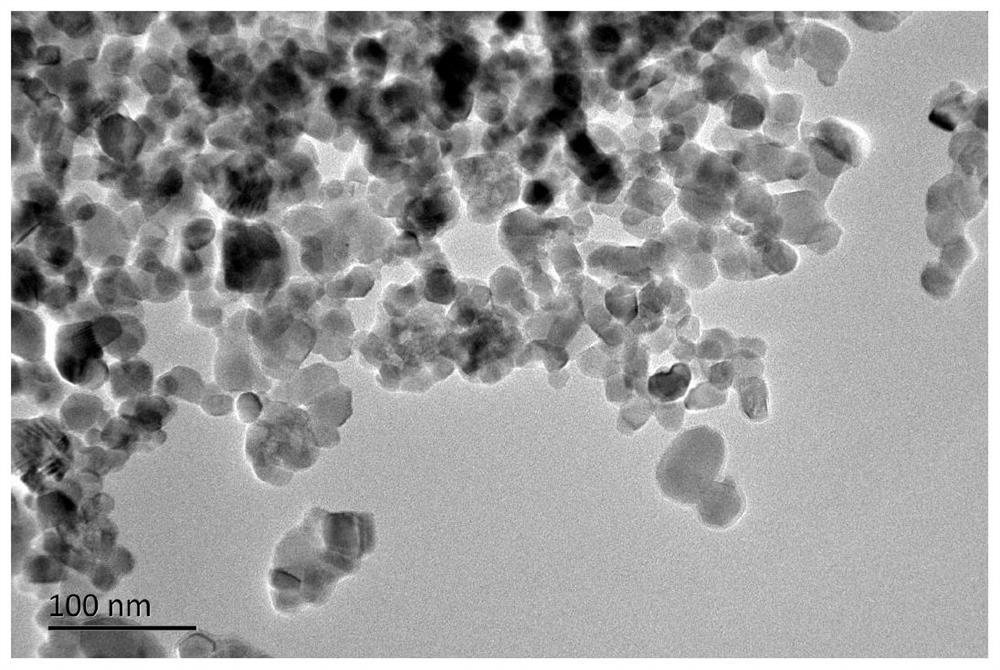

[0056] (2) Preparation of nitrogen-doped carbon dots: Weigh...

Embodiment 2

[0060] (1) Porous TiO 2 Film preparation: Weigh PEG-20000, add it into 10ml ultrapure water, and stir it magnetically to dissolve it; for PEG-20000 aqueous solution with a concentration of 15g / mL, take 62% PEG-20000 aqueous solution, and then add 25% nano-TiO 2 (P25), 1.5% acetylacetone and 7.5% dehydrated alcohol, magnetic stirring and ultrasonic stirring are alternately processed 5 times; after pouring into a mortar and grinding, adding 4% concentration is 5Vol.% Triton X100 aqueous solution, continue grinding until Uniform; FTO is arranged in a vertical column, and TiO 2 The slurry is coated on the surface of the FTO; placed at room temperature for a period of time, kept at 40°C for 50 minutes, and then put into a resistance furnace for sintering. The sintering temperature in the resistance furnace was uniformly raised from room temperature to 400°C at 4°C / min, and kept at this temperature for 40min.

[0061] (2) Preparation of nitrogen-doped carbon dots: weigh 2% of cott...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com