Preparation method of hydrocortisone sodium succinate for injection

A technology of hydrocortisone sodium succinate and hydrocortisone succinate, which is applied in the field of chemical pharmacy, can solve the problems of severe solvation of products, unqualified clarity, difficult filtration and separation, etc., to reduce alkalinity and quality Stable and reliable, high reconstitution clarity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

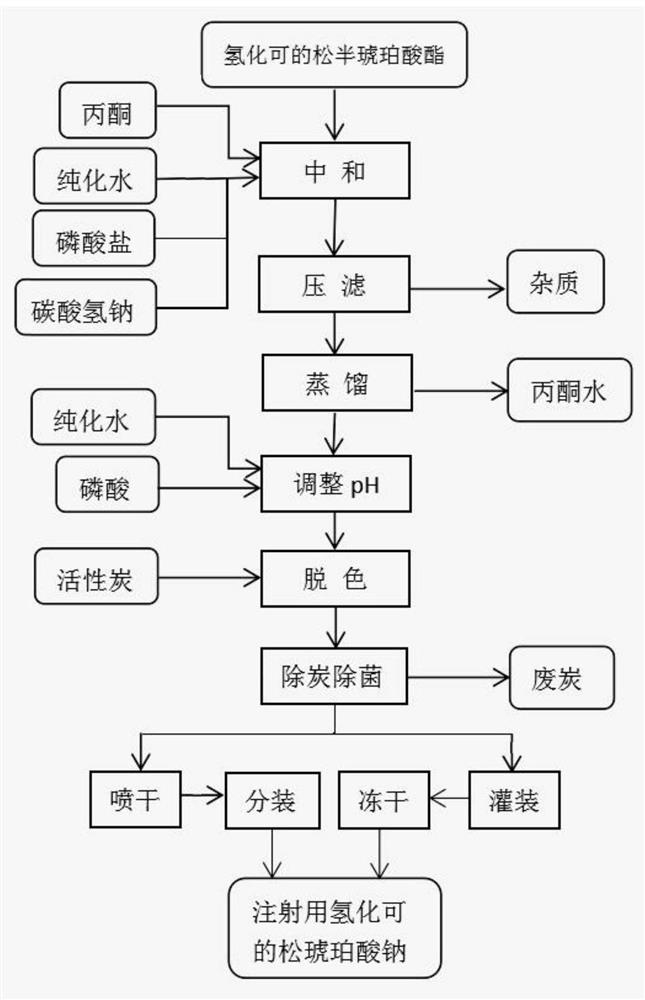

[0037] A preparation method for hydrocortisone sodium succinate for injection, comprising the following steps:

[0038] ①Stir 200g of acetone and 100g of hydrocortisone succinate at 20-30°C until suspended to obtain a suspension;

[0039] ② In addition, mix 700g of water, 25g of sodium bicarbonate, and 10g of phosphate mixture at a temperature of 20-30°C, fully stir to dissolve and exhaust, and make a mixed salt solution;

[0040] ③Control the temperature at 20-30°C, slowly add the mixed salt solution obtained in step ② into the suspension in step ①, and carry out neutralization reaction. After dissolving in about 30 minutes, cool the reaction system to 18°C, and slowly Stir at a high speed for 3h, then filter;

[0041] ④Below 40°C, vacuum distill half the volume of acetone water from the filtrate, then add some water to adjust the solution concentration to 15%;

[0042] ⑤Reduce the temperature of the solution in step ④ to 15-20°C, add 3g of activated carbon, adjust the pH t...

Embodiment 2

[0047] A preparation method for hydrocortisone sodium succinate for injection, comprising the following steps:

[0048] ①Put 160g of acetone and 100g of hydrocortisone succinate into the neutralization kettle, stir and suspend at 20-30°C to obtain a suspension;

[0049] ② Separately mix 400g of water, 18g of sodium bicarbonate, and 6g of phosphate at a temperature of 20-30°C, fully stir to dissolve and exhaust, and make a mixed salt solution;

[0050] ③Control the temperature at 20-30°C, slowly add the mixed salt solution obtained in step ② into the suspension in step ①, and carry out the neutralization reaction. After 30 minutes of dissolution, cool the reaction system to 13°C, and then slowly Stir for 6h, then filter;

[0051] ④Below 40°C, vacuum distill half of the volume of acetone water from the filtrate, then add an appropriate amount of water to adjust the total concentration of hydrocortisone sodium succinate and phosphate to 20%;

[0052] ⑤Reduce the temperature of ...

Embodiment 3

[0057] A preparation method for hydrocortisone sodium succinate for injection, comprising the following steps:

[0058] ①Stir and suspend 220g of acetone and 100g of hydrocortisone succinate at 20-30°C to obtain a suspension;

[0059] ② Separately mix 800g of water, 20g of sodium bicarbonate, and 8g of phosphate mixture at a temperature of 20-30°C, fully stir to dissolve and exhaust, and make a mixed salt solution;

[0060] ③Control the temperature at 20-30°C, slowly add the mixed salt solution obtained in step ② into the suspension in step ①, and carry out the neutralization reaction. After 30 minutes of dissolution, cool the reaction system to 15°C, and then slowly Stir for 5h, then filter;

[0061]④Below 40°C, vacuum distill half the volume of acetone water from the filtrate, and then add an appropriate amount of water to adjust the solution concentration to 10%;

[0062] ⑤Reduce the temperature of the solution in step ④ to 15-20°C, add 2g of activated carbon, adjust the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com