Preparation method and application of non-noble metal monatomic difunctional electrocatalyst

A non-precious metal, electrocatalyst technology, applied in chemical instruments and methods, physical/chemical process catalysts, circuits, etc., can solve the problems of low active site density, challenges in single-atom catalysts, high preparation costs, etc., and achieve excellent electrochemistry performance, superior electrocatalytic properties, and large active site density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

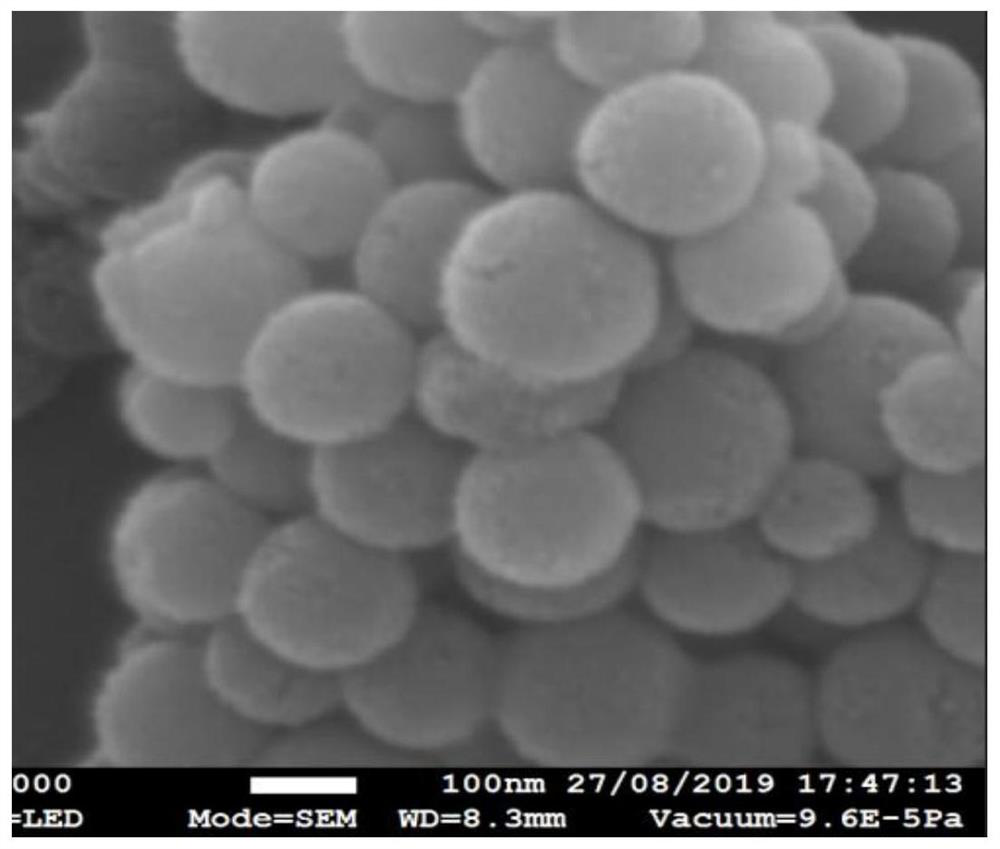

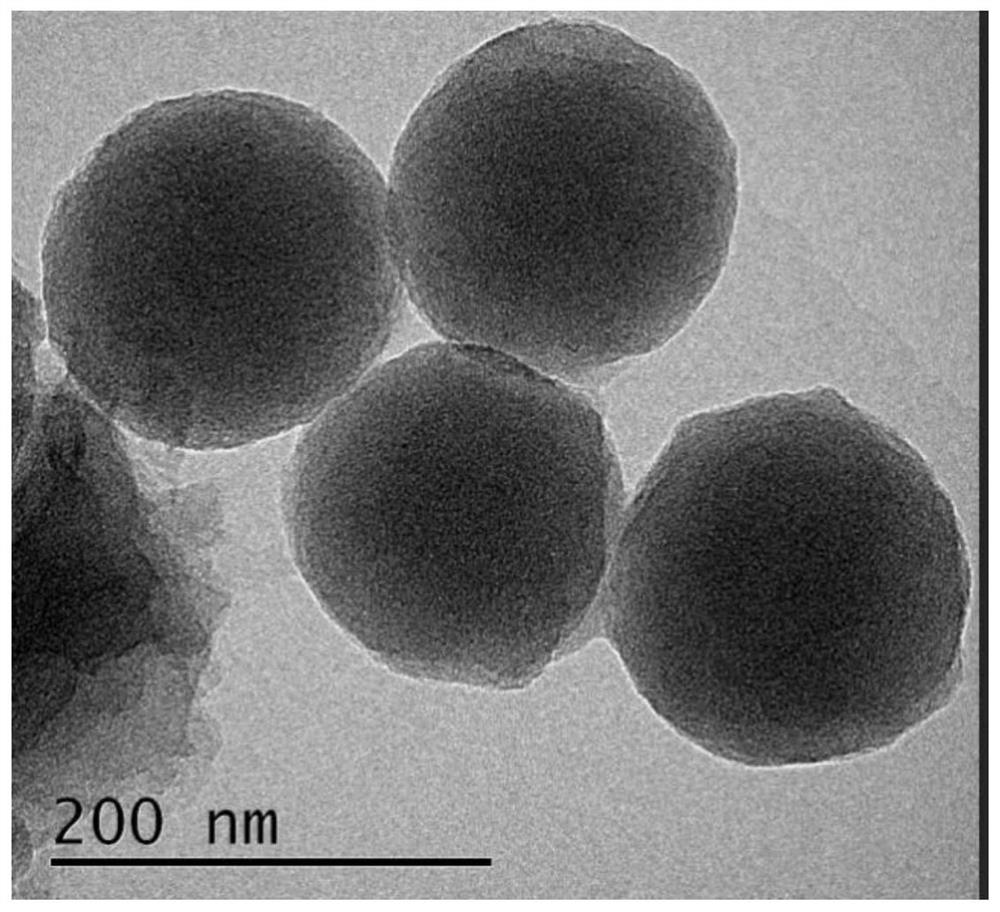

[0046] A method for preparing a non-noble metal monoatomic bifunctional electrocatalyst, specifically comprising the following steps:

[0047] 1) Weigh 150 mg of activated carbon spheres and add to 60 ml of deionized water to form A solution.

[0048] 2) Weigh 0.5g CuCl 2 2H 2 O, add 60ml deionized water to form B solution. .

[0049] 3) After mixing the solutions A and B, stir at room temperature for 20 h.

[0050] 4) Wash with deionized water and dry at 50 degrees.

[0051] 5) Grinding 100 mg of the powder obtained in step 4) with 500 mg of urea to obtain a mixed solid powder.

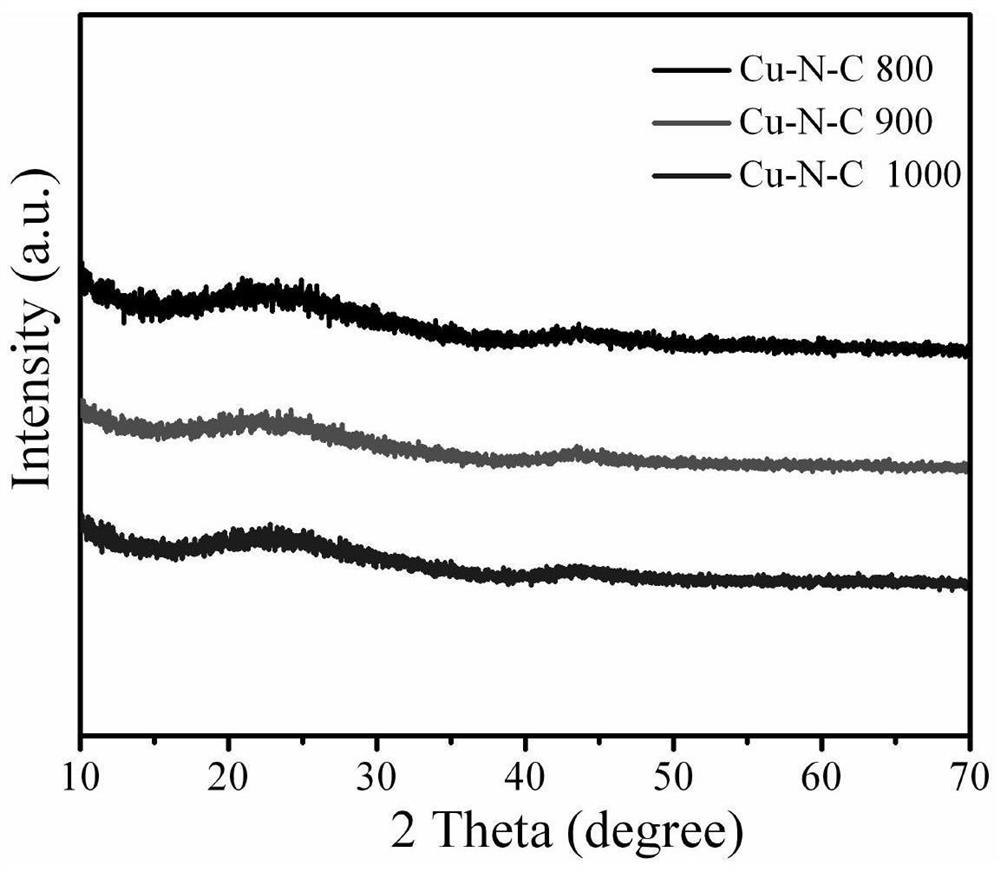

[0052] 6) Put the mixed solid powder obtained in step 5) in a tube furnace, under an inert gas, heat up to 500-1000°C at a heating rate of 2°C / min, and keep it warm for 3 hours to obtain.

Embodiment 2

[0054] A method for preparing a non-noble metal monoatomic bifunctional electrocatalyst, specifically comprising the following steps:

[0055] 1) Weigh 150 mg of activated carbon spheres and add to 60 ml of deionized water to form A solution 1.

[0056] 2) Weigh 0.5g Cu(NO 3 ) 2 , Add 60ml deionized water to form B solution.

[0057] 3) After mixing the solutions A and B, stir at room temperature for 20 h.

[0058] 4) Wash with deionized water and dry at 50 degrees.

[0059] 5) Grinding 100 mg of the powder obtained in step 4) with 500 mg of urea to obtain a mixed solid powder.

[0060] 6) Put the mixed solid powder obtained in step 5) in a tube furnace, under an inert gas, heat up to 1000°C at a heating rate of 2°C / min, and keep it warm for 3 hours to obtain.

Embodiment 3

[0062] A method for preparing a non-noble metal monoatomic bifunctional electrocatalyst, specifically comprising the following steps:

[0063] 1) Weigh 150 mg of activated carbon spheres and add to 60 ml of deionized water to form A solution.

[0064] 2) Weigh 0.5g Cu(CH 3 COO) 2 , Add 60ml deionized water to form B solution.

[0065] 3) After mixing the solutions A and B, stir at room temperature for 20 h.

[0066] 4) Wash with deionized water and dry at 50 degrees.

[0067] 5) Grinding 100 mg of the powder obtained in step 4) with 500 mg of urea to obtain a mixed solid powder.

[0068] 6) Put the mixed solid powder obtained in step 5) in a tube furnace, under an inert gas, heat up to 1000°C at a heating rate of 2°C / min, and keep it warm for 3 hours to obtain.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com