Pretreatment method of sucralose wastewater

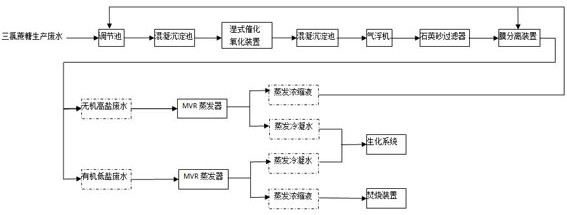

A sucralose and pretreatment technology, applied in food industry wastewater treatment, water/sewage treatment, heating water/sewage treatment, etc., can solve the problems of substandard effluent, many impurities, and difficult to degrade, so as to reduce cleaning times, Improved separation efficiency and improved biochemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A kind of pretreatment method of sucralose waste water, concrete implementation steps are as follows:

[0026] (1) Waste water produced by sucralose 5m 3 / h (CODcr at 100000mg / L) enters the regulating tank, uses air stirring, adds ammonia water with a mass concentration of 20% to the regulating tank to adjust the pH to 7.0, then pumps it into the stirring reactor, and adds 1500g of coagulant polyaluminum chloride and coagulant polyacrylamide 150g, control the pH of the wastewater to 7, settle for 2 hours, the wastewater enters the vertical flow sedimentation tank, the sediment is dehydrated by the screw dehydrator, the sediment mud cake is treated as hazardous waste, and the supernatant enters the wet catalytic oxidation The device carries out catalytic oxidation treatment, the pressure is 25MPa, the temperature is 210°C, the organic matter in the wastewater is cracked, and the macromolecules that are difficult to degrade such as heterocycles, rings, and long chains bec...

Embodiment 2

[0031] (1) Waste water produced by sucralose 2.5m 3 / h (CODcr at 100000mg / L) enters the regulating tank, uses air stirring, adds ammonia water with a mass concentration of 20% to the regulating tank to adjust the pH to 7.0, then pumps it into the stirring reactor, and adds 1000g of coagulant polyaluminum chloride And coagulant polyacrylamide 100g, control the pH of the wastewater to 7, settle for 2.2h, the wastewater enters the vertical flow sedimentation tank, the sediment is dehydrated by the screw dehydrator, the sediment mud cake is treated as hazardous waste, and the supernatant enters the wet catalytic The oxidation device carries out catalytic oxidation treatment, the pressure is controlled at 25MPa, the temperature is 210°C, the organic matter in the wastewater is cracked, and the macromolecular organic matter that is difficult to degrade such as heterocycle, ring, and long chain becomes small molecular organic matter, providing conditions for subsequent biochemistry; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com