PVC glove with strong ductility and preparation method thereof

A technology of ductility and gloves, which is applied in the direction of gloves, protective clothing, coatings, etc., can solve the problems of limited market share, poor scalability, and affecting operations, etc., and achieve the effects of facilitating heat transfer, fast polymerization rate, and convenient pipeline transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

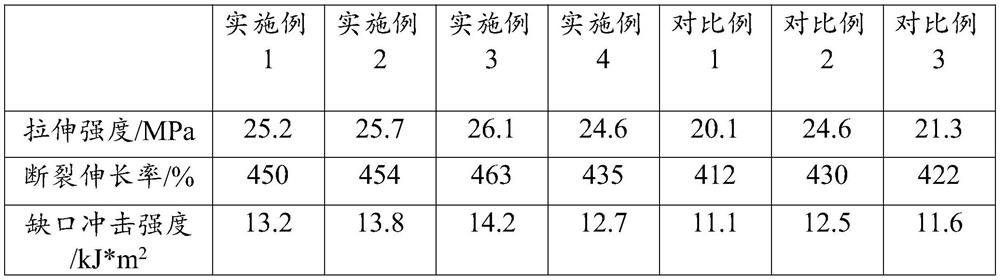

Examples

Embodiment 1

[0028] A preparation method of PVC gloves with strong ductility;

[0029] Step 1. Add 0.1g of sodium lauryl sulfate into 80g of water and stir to dissolve evenly, then add 100g of VCM and mix evenly, add 0.1g of oxidation-reduction initiator and mix evenly, adjust the pH value to 9, and react for polymerization at 45°C After 5 hours, the reaction resulted in a white emulsion, which was then spray-dried to obtain a white powder.

[0030] Step 2, 100g of PVC paste resin, 30g of acetyl citrate, 0.5g of calcium zinc stabilizer, 15g of D70, 5g of sodium carbonate aqueous solution and 0.5g of isopropyl triisostearyl titanate were mixed at 50°C Mix for 2 hours, after the slurry is obtained, vacuum defoaming at 25°C, the time of vacuum defoaming is 4 hours, and the pressure value of vacuum defoaming is -0.01MPa;

[0031] Step 3, dipping the glove model in the slurry at 70°C for 6 seconds, baking and plasticizing it under a nitrogen atmosphere at 220°C for 5 minutes, to obtain gloves ...

Embodiment 2

[0034] A preparation method of PVC gloves with strong ductility;

[0035] Step 1. Add 10g of emulsifier sodium lauryl sulfate into 104g of water and stir to dissolve evenly, then add 130g of VCM and mix evenly, add 3g of oxidation-reduction initiator calcium peroxide and 1-aminobutanol, mix evenly, and adjust the pH The value was 9, and the reaction polymerization was carried out at 45° C. for 5 hours to obtain a white emulsion, which was then spray-dried to obtain a white powder.

[0036] Step 2. Blend 100g of PVC paste resin, 40g of acetyl citrate, 1g of calcium zinc stabilizer, 20g of D70, 5g of sodium carbonate aqueous solution and 1g of isopropyl triisostearyl titanate at 50°C for 2h , after obtaining the slurry, vacuum defoaming at 25°C, the time of vacuum defoaming is 4h, and the pressure value of vacuum defoaming is -0.01MPa;

[0037] Step 3, dipping the glove model in the slurry at 70°C for 6 seconds, baking and plasticizing for 5 minutes under a nitrogen atmosphere ...

Embodiment 3

[0040] A preparation method of PVC gloves with strong ductility;

[0041] Step 1. Add 0.5g of emulsifier sodium lauryl sulfate into 80g of water and stir to dissolve evenly, then add 100g of VCM and mix evenly, then add 0.5g of oxidation-reduction initiator calcium peroxide and 1-aminobutanol and mix evenly. Adjust the pH value to 9, react and polymerize at 45° C. for 5 hours to obtain a white emulsion, which is further spray-dried to obtain a white powder.

[0042] Step 2. Blend 100g of PVC paste resin, 40g of acetyl citrate, 1g of calcium zinc stabilizer, 20g of D70, 5g of sodium carbonate aqueous solution and 1g of isopropyl triisostearyl titanate at 50°C for 2h , after obtaining the slurry, vacuum defoaming at 25°C, the time of vacuum defoaming is 4h, and the pressure value of vacuum defoaming is -0.01MPa;

[0043] Step 3, dipping the glove model in the slurry at 70°C for 6 seconds, baking and plasticizing for 5 minutes under a nitrogen atmosphere at 180-220°C, to obtain ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com