Medical soft PVC material suitable for electron beam irradiation sterilization and preparation method thereof

A technology of PVC material and electron beam irradiation, which is applied in the field of modification of medical PVC materials, can solve the problems of mechanical property decline, yellowing of medical PVC materials, etc., and achieve the effect of easy absorption, preventing PVC degradation, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

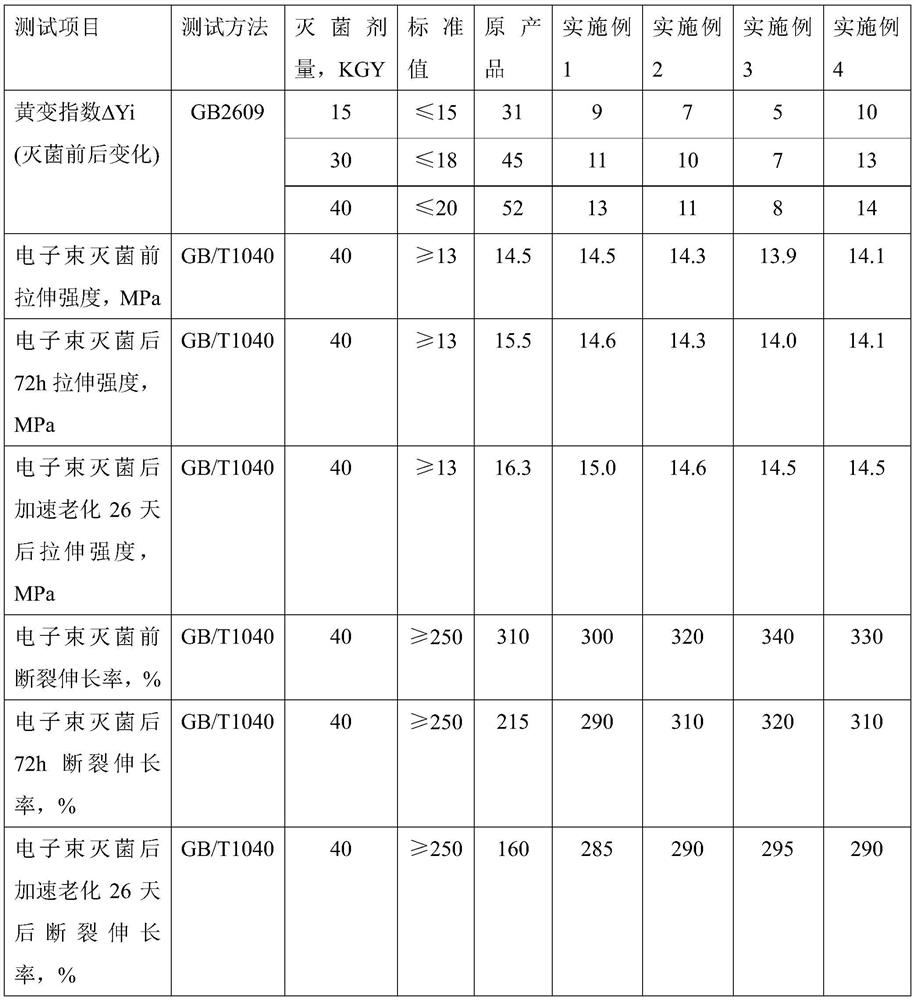

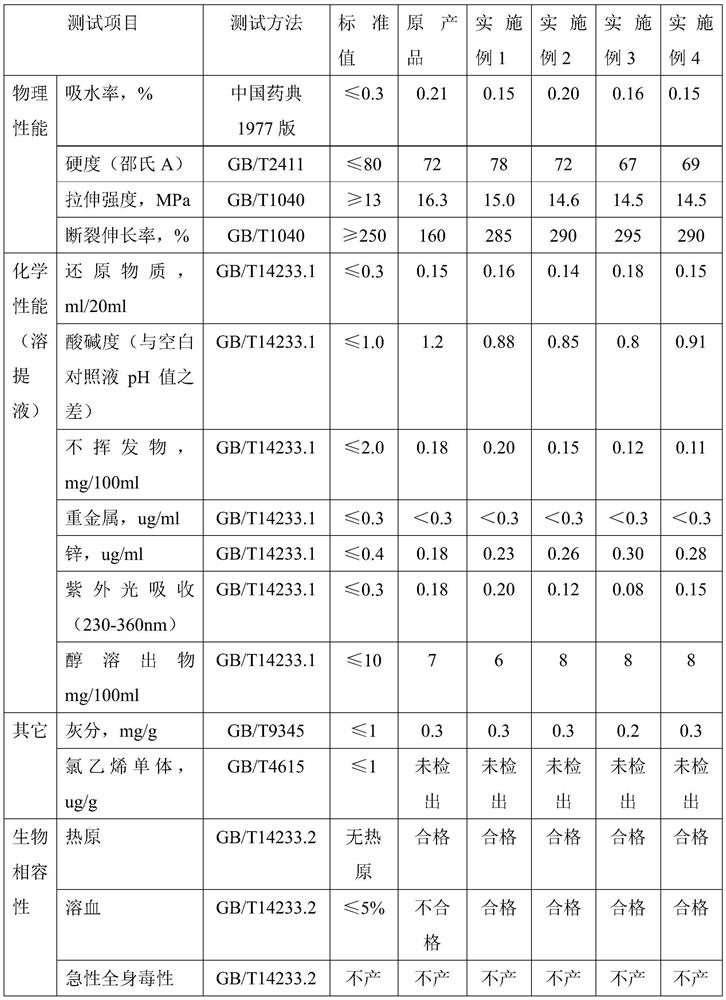

Examples

Embodiment 1

[0028] The material provided by the invention is formulated by weight ratio from the following raw materials:

[0029] Medical PVC resin powder: 100 parts;

[0030] Plasticizer DEHP: 40 parts;

[0031] Ultrafine calcium / zinc stabilizer: 1.5 parts;

[0032] Auxiliary heat stabilizer: 12 parts;

[0033] Antioxidant 2246S: 0.25 parts;

[0034] Antioxidant DSTP: 0.25 parts;

[0035] Lubricant: 1.0 parts.

[0036] The ultrafine calcium / zinc stabilizer is composed of 30-60% calcium stearate, 5-10% zinc glycerol, 5-10% zinc acetylacetonate, 10-20% stearoylbenzoylmethane , 5-15% of 1,3-diphenylpropanedione-rare earth metal organic complexes and 10-25% of bis(2,4-di-tert-butylphenol) pentaerythritol diphosphite; The auxiliary heat stabilizer is epoxy linseed oil; the lubricant is composed of 40-60% stearic acid and 40-60% polyethylene wax.

[0037] Specific production steps:

[0038] 1) Zinc stearate, zinc glycerol, zinc acetylacetonate, stearyl benzoyl methane, 1,3-diphenylpro...

Embodiment 2

[0043] The material provided by the invention is formulated by weight ratio from the following raw materials:

[0044] Medical PVC resin powder: 100 parts;

[0045] Plasticizer DEHP: 60 parts;

[0046] Ultrafine calcium / zinc stabilizer: 1 part;

[0047] Auxiliary heat stabilizer: 10 parts;

[0048]Antioxidant 2246S: 0.2 parts;

[0049] Antioxidant DLTP: 0.1 parts;

[0050] Lubricant: 0.8 parts.

[0051] The ultrafine calcium / zinc stabilizer is composed of 30-60% calcium stearate, 5-10% zinc glycerol, 5-10% zinc acetylacetonate, 10-20% stearoylbenzoylmethane , 5-15% of 1,3-diphenylpropanedione-rare earth metal organic complexes and 10-25% of bis(2,4-di-tert-butylphenol) pentaerythritol diphosphite; the auxiliary The heat stabilizer is epoxy linseed oil; the lubricant is composed of 40-60% stearic acid and 40-60% polyethylene wax.

[0052] The preparation method is the same as in Example 1.

Embodiment 3

[0054] The material provided by the invention is formulated by weight ratio from the following raw materials:

[0055] Medical PVC resin powder: 100 parts;

[0056] Plasticizer DEHP: 70 parts;

[0057] Ultrafine calcium / zinc stabilizer: 1.2 parts

[0058] Auxiliary heat stabilizer: 8 parts;

[0059] Antioxidant 2246S: 0.1 parts;

[0060] Antioxidant DLTP: 0.1 parts;

[0061] Lubricant: 0.5 parts.

[0062] The ultrafine calcium / zinc stabilizer is composed of 30-60% calcium stearate, 5-10% zinc glycerol, 5-10% zinc acetylacetonate, 10-20% stearoylbenzoylmethane , 5-15% of 1,3-diphenylpropanedione-rare earth metal organic complexes and 10-25% of bis(2,4-di-tert-butylphenol) pentaerythritol diphosphite; The auxiliary heat stabilizer is epoxy linseed oil; the lubricant is composed of 40-60% stearic acid and 40-60% polyethylene wax.

[0063] The preparation method is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com