Preparation method of metal-fullerene composite nano-powder

A nano-powder and fullerene technology, applied in the field of fullerene, can solve problems such as the introduction of impurities, restrictions on material types, and the inability to prepare highly active metals, and achieve the effect of small metal restrictions and reduced usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029]A method for preparing metal-fullerene composite nano powder is prepared by using a roll-to-roll coating machine. Specifically, it includes the following processes:

[0030](1) Install organic film coils as organic substrates in the roll-to-roll coating machine;

[0031](2) Put high-purity metal and high-purity fullerene powder into the evaporation source of the coating machine. The evaporation source corresponding to the metal can be a resistance heating source, an induction heating source, or a focused electron beam heating source. The heating source corresponding to the fullerene powder adopts a resistance heating source.

[0032](3) Start the vacuum pumping system to pump the vacuum chamber to high vacuum;

[0033](4) Turn on the evaporation power supply and adjust the input power so that stable metal vapor and fullerene vapor are formed at the evaporation source, and the two vapors are co-deposited on the substrate; adjust the volume of the organic film substrate according to the nee...

Embodiment 1

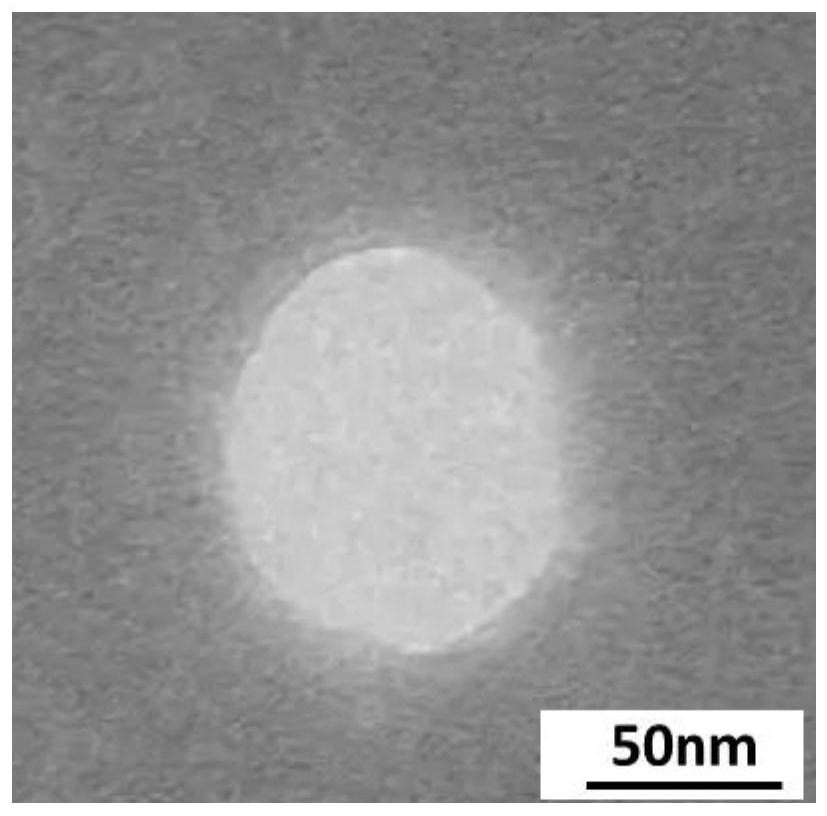

[0037]In the preparation process, the PE film is used as the organic substrate, and the vacuum degree of the vacuum chamber background is 5×10-4Pa; the parameter conditions are: the rotation speed of the PE film is 5 m / min, the temperature of the PE film is 25 degrees; the heating temperature of the aluminum source is 750 degrees; The fullerene heating temperature is 500 degrees; the PE film reciprocates 10 times, and the resistance value of the composite film is measured to be 1.5 megaohms; take out the composite film and immerse it in acetone. After the substrate is completely dissolved, filter to obtain the powder, and the powder is tested by scanning electron microscope. It can be seen that the diameter of the powder is about 50 nanometers. It can be seen that the nanoparticles in the aluminum-fullerene composite film obtained are completely non-adhesive, and the subsequent organic matrix dissolution and removal can obtain extremely uniform and spherical nanometer powders. Body,...

Embodiment 2

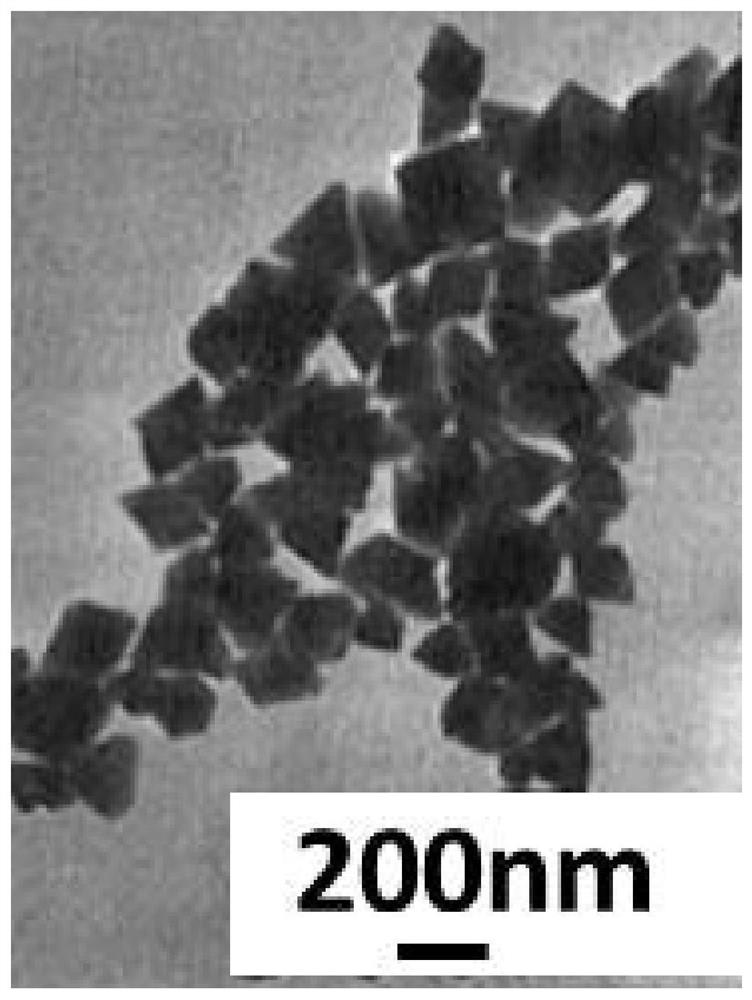

[0039]During the preparation process, the PE film is used as the substrate, the vacuum degree of the vacuum chamber is 5×10-4Pa; the parameter conditions: the rotation speed of the PE film is 5 m / min, the temperature of the PE film is 25 degrees; the heating temperature of the aluminum source is 750 degrees; the fullerene The heating temperature is 500 degrees; the PE film reciprocates 20 times, and the resistance value of the composite film is 700 kohm; take out the composite film, immerse it in acetone, and filter the powder after the substrate is completely dissolved. The powder is tested by scanning electron microscopy, and the particle size is known. About 230 nanometers, see for detailsfigure 2As shown, the nano powder is a relatively uniform flake-like nano powder, the thickness of the flake is about 70 nanometers to 100 nanometers, and the length (width) of the flake is 100 nanometers to 300 nanometers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com