High-stability in-glaze color domestic porcelain and production process thereof

A technology with high stability and high production technology, which is applied in the field of in-glaze daily-use porcelain, can solve the problems of in-glaze daily-use porcelain stability, smoothness, and long firing time of in-glaze daily-use porcelain , to achieve the effect of reducing the firing time, high yield and smooth appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A high-stability in-glaze porcelain for daily use, including raw materials, the mass ratio of raw materials is: 50 parts of kaolin, 3 parts of feldspar, 3 parts of calcium oxide, 5 parts of bone meal, 1 part of aluminum oxide, and 3 parts of silicon dioxide 5 parts of starch, 1 part of sodium oxide, 1 part of titanium oxide, 1 part of defoamer, 3 parts of talcum powder, and the feldspar can be potassium sodium feldspar.

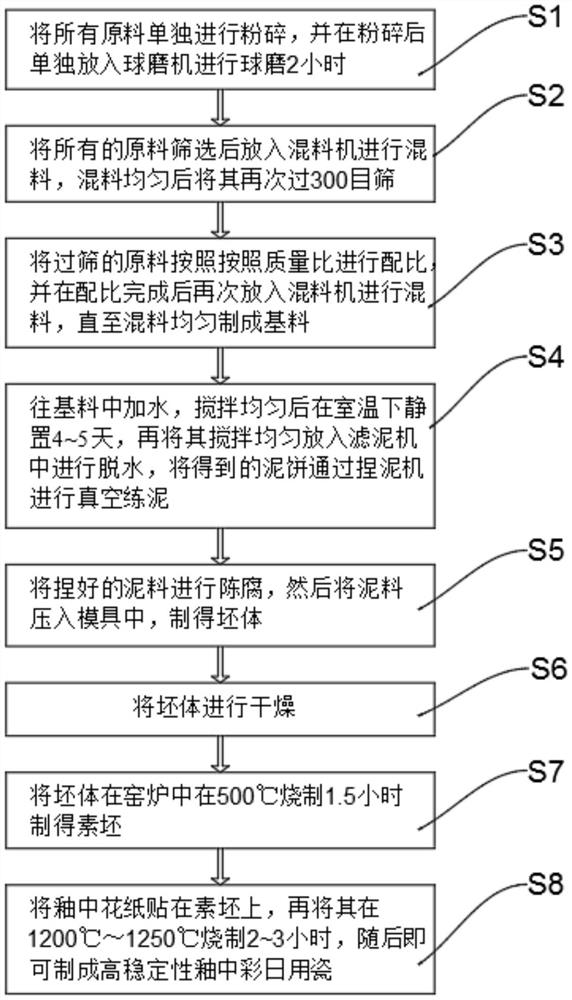

[0034] A production process of high-stability in-glaze daily-use porcelain, comprising the following steps:

[0035] S1: Pulverize all the raw materials separately, put them into a ball mill for 2 hours after pulverization, and pass each raw material after ball milling through a 300-mesh sieve;

[0036] S2: After screening all the raw materials, put them into the mixer for mixing. After mixing evenly, pass them through a 300-mesh sieve again, and remove the iron after the raw materials are sieved;

[0037] S3: Proportion the sieved raw materials accor...

Embodiment 2

[0044] The mass ratio of raw materials is: 55 parts of kaolin, 5 parts of feldspar, 5 parts of calcium oxide, 10 parts of bone meal, 3 parts of aluminum oxide, 5% of silicon dioxide, 5 parts of starch, 2 parts of sodium oxide, and 2 parts of titanium oxide. 3 parts, 3 parts of defoaming agent, 5 parts of talcum powder, and the feldspar can be potassium sodium feldspar.

[0045] A production process of high-stability in-glaze daily-use porcelain, comprising the following steps:

[0046] S1: Pulverize all the raw materials separately, put them into a ball mill for 2 hours after pulverization, and pass each raw material after ball milling through a 300-mesh sieve;

[0047] S2: After screening all the raw materials, put them into the mixer for mixing. After mixing evenly, pass them through a 300-mesh sieve again, and remove the iron after the raw materials are sieved;

[0048] S3: Proportion the sieved raw materials according to the mass ratio, and put them into the mixer for mix...

Embodiment 3

[0055] The mass ratio of raw materials is: 60 parts of kaolin, 8 parts of feldspar, 8 parts of calcium oxide, 15 parts of bone meal, 5 parts of aluminum oxide, 8% of silicon dioxide, 10 parts of starch, 3 parts of sodium oxide, and 3 parts of titanium oxide. 5 parts, 5 parts of defoaming agent, 8 parts of talcum powder, and the feldspar can be potassium sodium feldspar.

[0056] A production process of high-stability in-glaze daily-use porcelain, comprising the following steps:

[0057]S1: Pulverize all the raw materials separately, put them into a ball mill for 2 hours after pulverization, and pass each raw material after ball milling through a 300-mesh sieve;

[0058] S2: After screening all the raw materials, put them into the mixer for mixing. After mixing evenly, pass them through a 300-mesh sieve again, and remove the iron after the raw materials are sieved;

[0059] S3: Proportion the sieved raw materials according to the mass ratio, and put them into the mixer for mix...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap