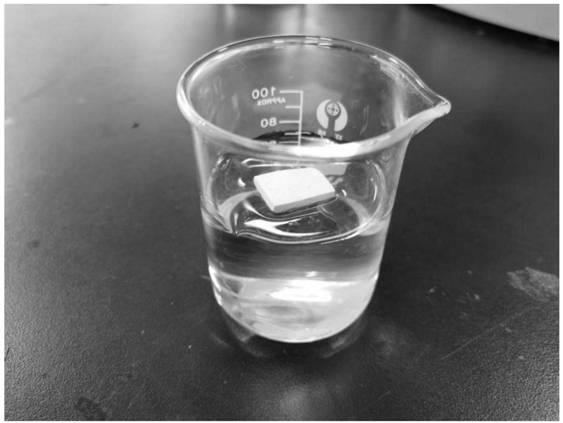

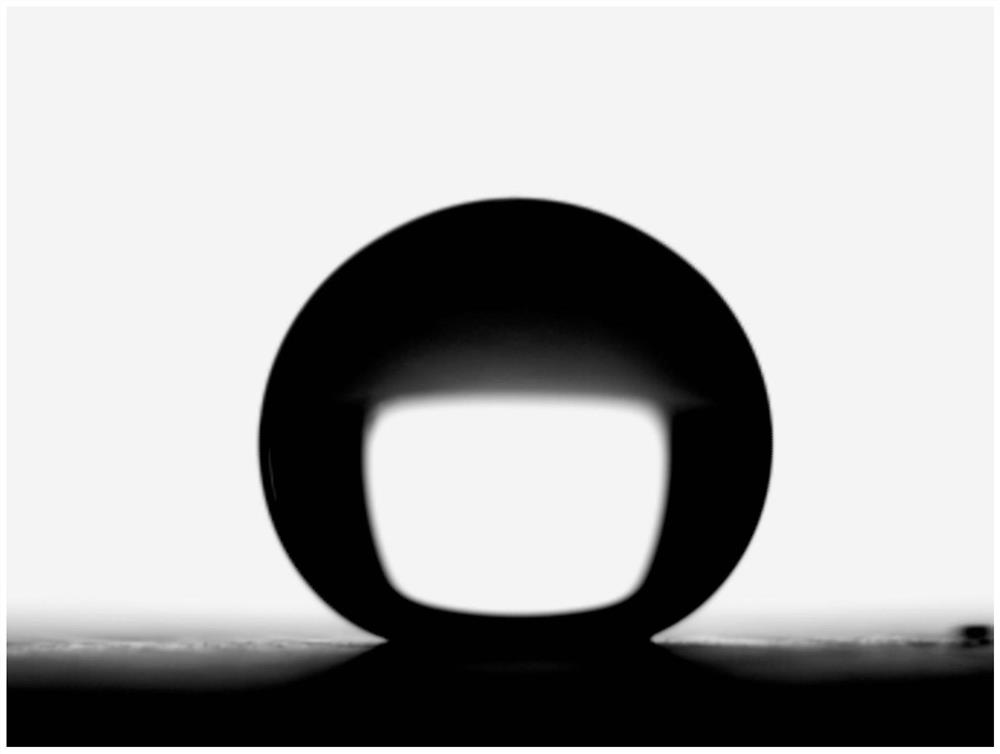

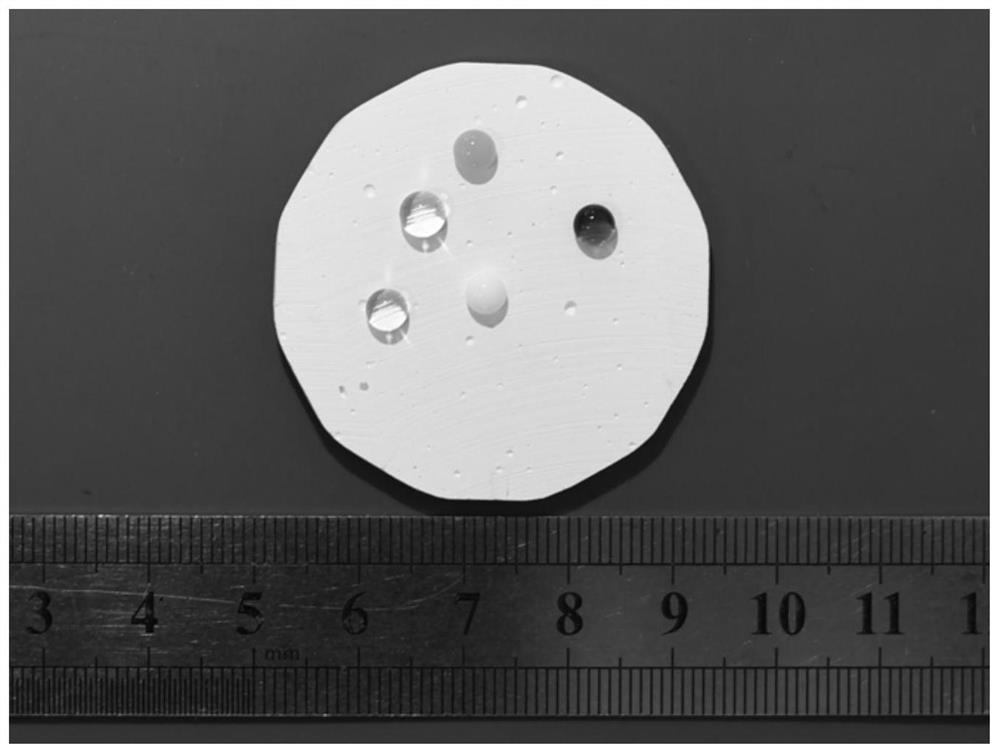

Self-cleaning light-weight high-strength porous ceramic taking waste glass as raw material as well as preparation method and application of self-cleaning light-weight high-strength porous ceramic

A porous ceramic and self-cleaning technology, applied in ceramic products, applications, and other household appliances, etc., can solve the problems of backward recycling technology of waste glass, achieve significant economic and social benefits, solve difficult recycling technologies, and simple preparation methods Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] 1. Weigh the powder (alumina powder with an average particle size of 0.2um and glass powder with an average particle size of 2.5um at a mass ratio of 1:1), and then press the mass ratio of powder and water in a ball mill jar Add deionized water at a ratio of 2.7:1, and adjust the pH of the solvent water to about 2 with an acid-base regulator. Add the above-mentioned weighed powder into the solvent spoon by spoon, stir while adding, after stirring evenly, under the state of rapid stirring (300r / min), add propionic acid and polyvinyl alcohol (the addition of propionic acid is according to each g powder is calculated by adding 0.04mmol propionic acid, and the amount of polyvinyl alcohol is calculated according to 1wt% of the powder mass), after stirring for 5-10min, add n-octane in an amount of oil-water volume ratio of 2:1, and grind The mass ratio of the ball to the ceramic powder is 1:1, adding alumina grinding balls. The speed of the ball mill is 300r / min. After ball ...

Embodiment 2

[0039] 1. Weigh the powder (alumina powder with an average particle size of 0.4um and glass powder with an average particle size of 2.5um at a mass ratio of 1:2), and then press the mass ratio of powder and water in a ball mill jar Add deionized water at a ratio of 1:1, and adjust the pH of the solvent water to 2 with an acid-base regulator. Add the above-mentioned weighed powder into the solvent one by one, stir while adding, after stirring evenly, under the state of rapid stirring (about 300r / min), add propionic acid and polyvinyl alcohol (the addition of propionic acid is according to Add 0.08mmol propionic acid per gram of powder, the amount of polyvinyl alcohol added is based on 2wt% of the powder mass), after stirring for 5-10min, add n-octane according to the oil-water volume ratio of 1:1, Add alumina grinding balls according to the mass ratio of grinding balls and ceramic powder at 1:1. The speed of the ball mill is 350r / min. After 12 hours of ball milling, inject the...

Embodiment 3

[0043] 1. Weigh the powder (alumina powder with an average particle size of 0.2um and glass powder with an average particle size of 2.5um at a mass ratio of 2:1), and then press the powder to water mass ratio in a ball mill jar Add deionized water at a ratio of 2:1, and adjust the pH of the solvent water to 2 with an acid-base regulator. The above-mentioned powders weighed are added into the solvent one by one spoonfuls, and stirred while adding, after stirring evenly, under the state of rapid stirring (300r / min), add valeric acid and polyethylene glycol (the addition of valeric acid is according to Add 0.08mmol propionic acid per gram of powder, the amount of polyethylene glycol added is calculated according to 2wt% of the powder mass), after stirring for 5-10min, add hexadecane at an oil-water volume ratio of 1:1 alkanes, according to the mass ratio of grinding balls and ceramic powder 1:1, add alumina grinding balls. The speed of the ball mill is 350r / min. After 12 hours o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com