Slope-induced self-assembled colloidal crystals based on industrial applications and preparation methods thereof

A technology of colloidal crystals and self-assembly, applied in self-gel state, chemical instruments and methods, crystal growth, etc., can solve the problems of cumbersome process, long production cycle, complicated production process, etc., and achieve easy industrialization and not easy Volatile, low-cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Embodiment 1: Using the present invention to realize the assembly of polystyrene beads with a diameter of 370 nm into a single-layer colloidal crystal.

[0045] (1) Select a silicon wafer with a size of 20mm×20mm×400μm as the chip substrate, clean the substrate according to the standard RCA method, and then hydrophilize it. The hydrophilization treatment method is to soak the substrate in a mixture of hydrogen peroxide and concentrated sulfuric acid for at least 6 hours. The volume ratio of hydrogen peroxide and concentrated sulfuric acid is not strictly limited. This experiment uses a volume ratio of hydrogen peroxide and concentrated sulfuric acid of 1:3.

[0046] (2) Wash the self-made polystyrene beads with a diameter of 370nm twice, and then disperse them in the mixed solution of ethanol and ethylene glycol (8:1 volume ratio), where the volume fraction of the beads in the mixed solution is 3%.

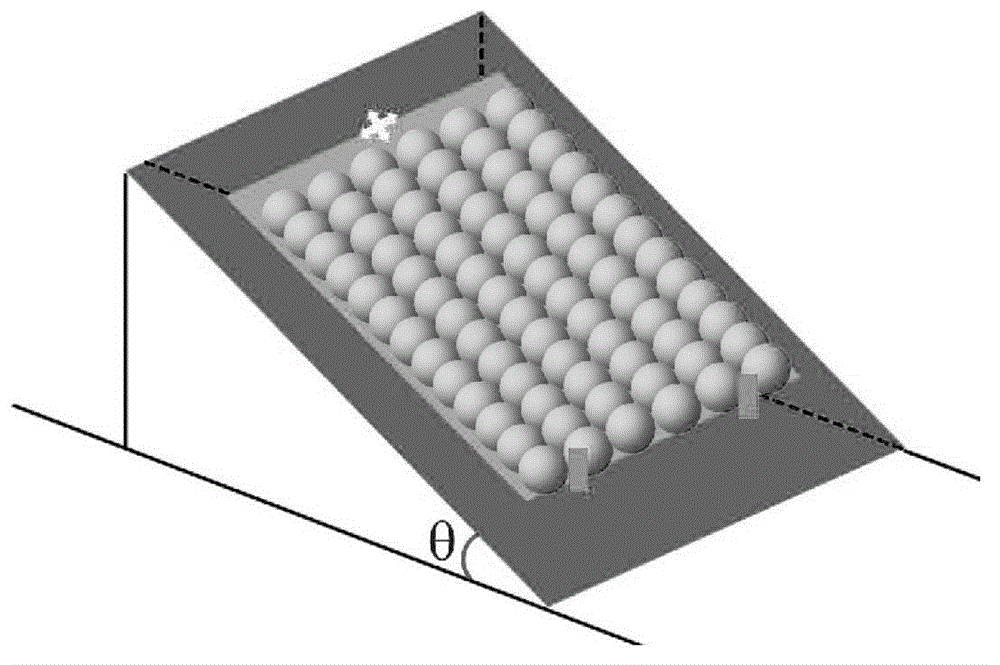

[0047] (3) Fix the substrate obtained in step (1) on a slope with an...

Embodiment 2

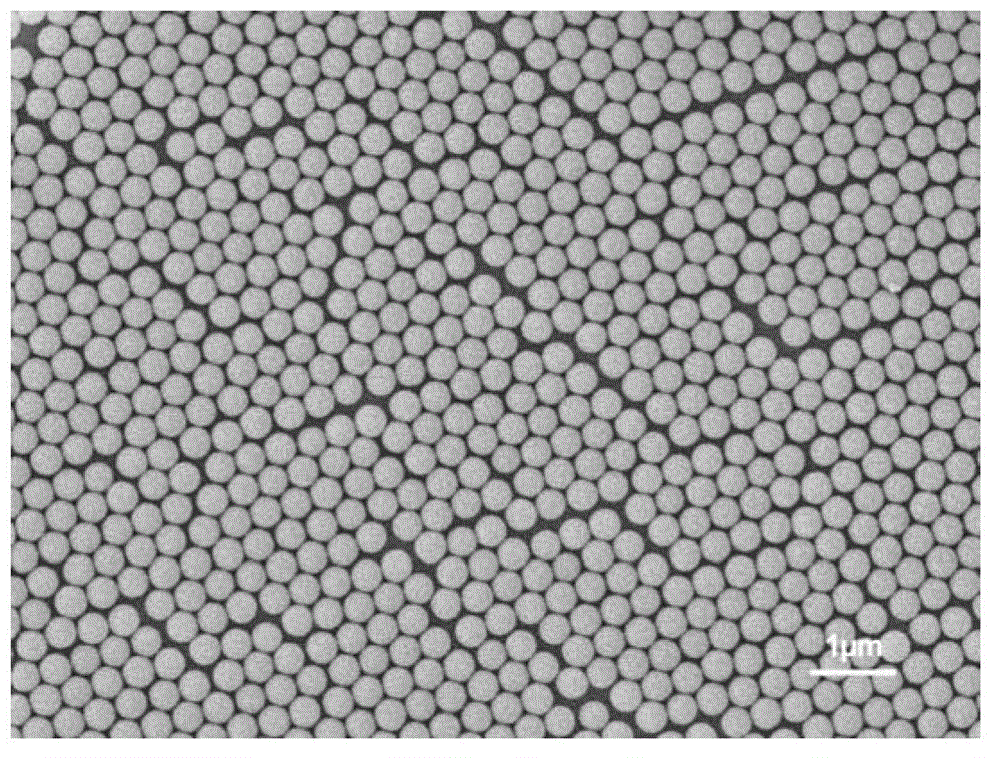

[0052] Embodiment 2: Using the present invention to realize the assembly of polystyrene beads with a diameter of 460 nm into a single-layer colloidal crystal.

[0053] (1) Select a silicon wafer with a size of 40mm×40mm×400μm as the chip substrate, clean the substrate according to the standard RCA procedure, and then hydrophilize it. For the hydrophilization treatment method, refer to step (1) of Example 1.

[0054] (2) Wash the self-made polystyrene beads with a diameter of 460nm twice, and then disperse them in a mixture of ethanol and ethylene glycol (volume ratio 6:1), where the volume fraction of the beads in the mixture is 10%.

[0055] (3) Fix the substrate obtained in step (1) on a slope with an inclination angle of 30°.

[0056] (4) Put the inclined plane containing the substrate into an incubator, and set the temperature of the incubator to 75°C.

[0057] (5) Take 120 μL of the monodisperse polystyrene nanosphere glue solution obtained in step (2) and drop it on t...

Embodiment 3

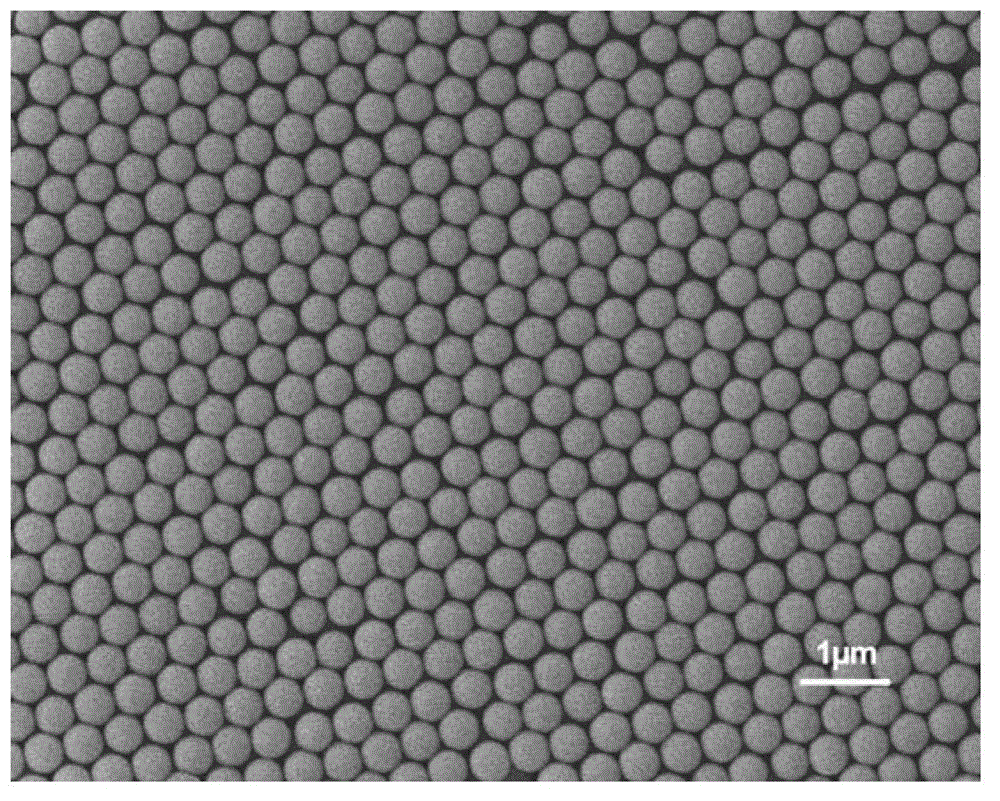

[0060] Embodiment 3: Using the present invention to realize the assembly of polystyrene beads with a diameter of 3 μm into a single-layer colloidal crystal.

[0061] (1) Select a silicon wafer with a size of 20mm×20mm×400μm as the chip substrate, clean the substrate according to the standard RCA procedure, and then hydrophilize it. For the hydrophilization treatment method, refer to step (1) of Example 1.

[0062] (2) Wash the self-made polystyrene beads with a diameter of 3 μm twice, and then disperse them in a mixture of ethanol and ethylene glycol (volume ratio 5:1), where the volume fraction of the beads in the mixture is 15%.

[0063] (3) Fix the substrate obtained in step (1) on a slope with an inclination angle of 85°.

[0064] (4) Put the inclined plane containing the substrate into an incubator, and set the temperature of the incubator to 80°C.

[0065] (5) Take 30 μL of the monodisperse polystyrene nanosphere glue solution obtained in step (2) and drop it on the t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com