Preparation method of salbutamol sulfate impurities

A technology for salbutamol sulfate and impurities, which is applied in the field of preparation of salbutamol sulfate impurities, can solve the problems that the preparation method has not been reported in the literature, and achieve the effects of mild and controllable reaction conditions, high yield, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

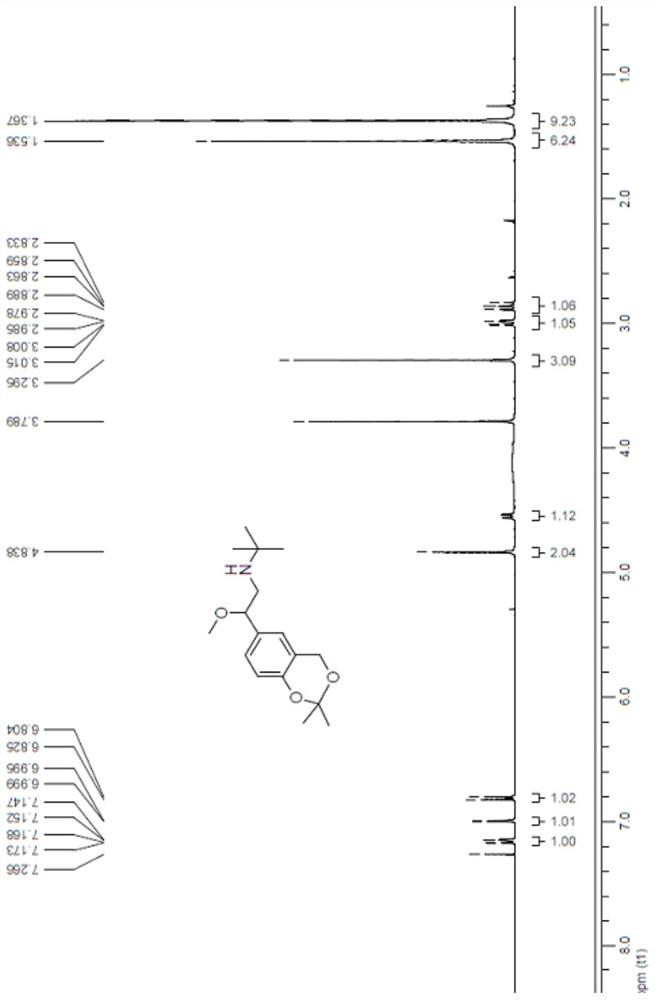

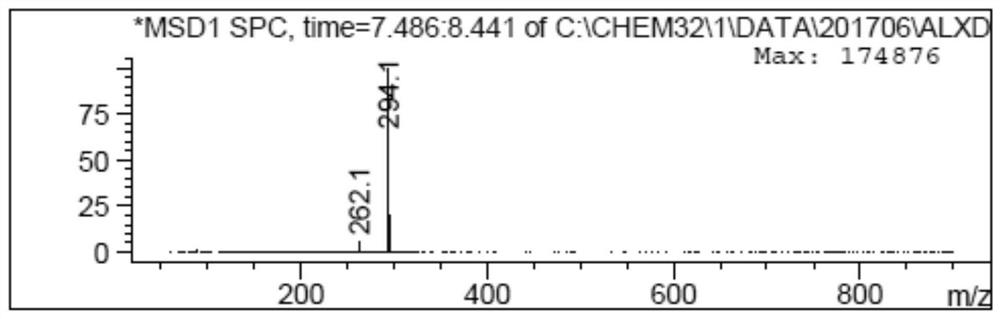

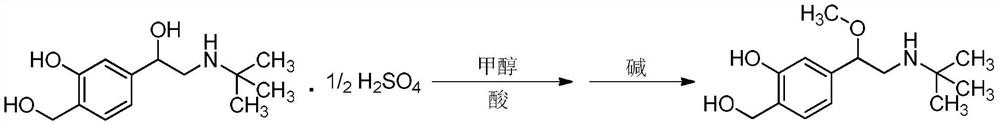

[0029] Preparation of methyl ether intermediate

[0030]

[0031] Take 100ml of methanol, add 5.0g of salbutamol sulfate, add 1ml of 37% hydrochloric acid; keep the reaction at 10-20°C for 16 hours, and TLC shows that the reaction is complete.

[0032] Post-processing: Add sodium bicarbonate to the reaction solution until the solution is alkaline, concentrate to dryness, add 30ml of water, extract with 2*30ml of dichloromethane, dry the organic phase with anhydrous sodium sulfate, concentrate to dryness, and use column layer Analysis and purification, the eluent is petroleum ether: ethyl acetate = 2:1-1:1, 1.0 g of methyl ether intermediate was obtained, and the yield was 23%.

Embodiment 2

[0034] Preparation of methyl ether intermediate

[0035]

[0036] Take methanol 60ml, add salbutamol sulfate 3.0g, add 98% sulfuric acid 0.2ml. The reaction was incubated at 10-20° C. for 16 hours, and TLC showed that the reaction was complete.

[0037] Post-processing: Add sodium bicarbonate to the reaction solution until the solution is alkaline, concentrate to dryness, add 20ml of water, extract with 2*15ml of dichloromethane, dry the organic phase with anhydrous sodium sulfate, concentrate to dryness, and use column layer Analysis and purification, the eluent is petroleum ether:ethyl acetate=2:1-1:1, 0.52g of methyl ether intermediate was obtained, and the yield was 20%.

Embodiment 3

[0039] Preparation of methyl ether intermediate

[0040]

[0041] Take 60ml of methanol, add 3.0g of salbutamol sulfate, and add 0.6ml of 37% hydrochloric acid. The reaction was incubated at 10-20° C. for 16 hours, and TLC showed that the reaction was complete.

[0042] Post-processing: Add sodium carbonate to the reaction solution until the solution is alkaline, concentrate to dryness, add 20ml of water, extract with 2*15ml of dichloromethane, dry the organic phase with anhydrous sodium sulfate, concentrate to dryness, and perform column chromatography For purification, the eluent was petroleum ether:ethyl acetate=2:1-1:1, and 0.59 g of methyl ether intermediate was obtained with a yield of 23%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com