A kind of production technology of tremella oligosaccharide

A production process, tremella technology, applied in the direction of sugar derivatives, sugar derivatives, sugar derivatives preparation, etc., can solve the problems of insoluble in water, large molecular weight, strong viscosity, etc., to reduce production environment requirements, composition The effect of simple, controllable degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

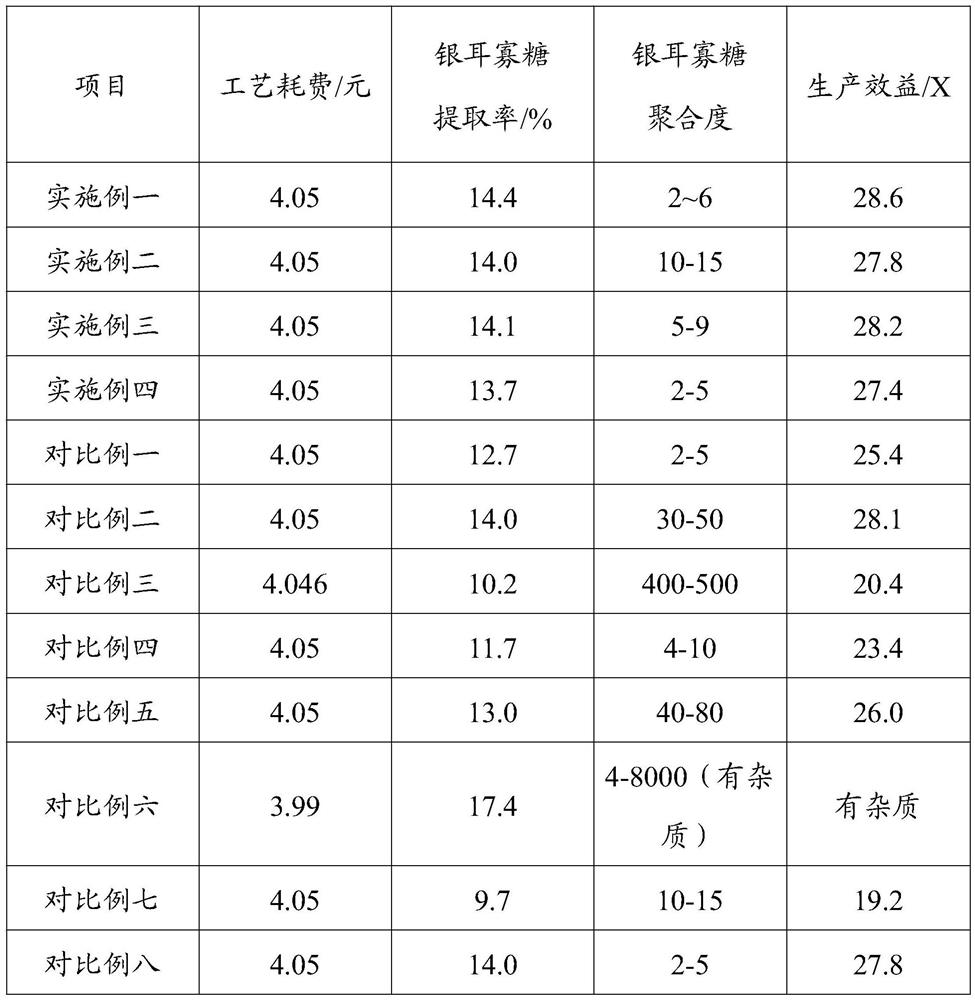

Examples

Embodiment 1

[0041] The preparation method of tremella oligosaccharide in the present embodiment, concrete steps are as follows:

[0042] Step 1: screening and culturing strains, preparing components and their concentrations are: tremella polysaccharide 2g / L, peptone 5g / L, yeast powder 1g / L, iron phosphate 0.01g / L, and the solvent is tap water, the pH of the mixture is =7.4, sterilize the culture medium at 121°C for 20 minutes, at a temperature of 28°C and a shaking speed of 180rpm, select rotten Tremella fungus for shaking culture in the culture liquid, dilute the shaken culture liquid by more than one dilution, and apply The components and their concentrations are as follows: tremella polysaccharide 15g / L, agarose 6g / L, peptone 5g / L, yeast powder 1g / L, iron phosphate 0.01g / L, and the solvent is tap water, and the pH of the mixture is = 7.4. Sterilize at 121°C for 20 minutes to screen the medium plate, make more than three parallel samples for each dilution, incubate the plate upside down...

Embodiment 2

[0047] The preparation method of tremella oligosaccharide in the present embodiment, concrete steps are as follows:

[0048] Step 1, strain screening and cultivation, preparation of each component and its concentration are: white fungus polysaccharide 1g / L, peptone 3g / L, yeast powder 0.5g / L, iron phosphate 0.01g / L, and the solvent is tap water, the mixed solution pH = 7.4, sterilized at 121°C for 20 minutes in the culture medium, at a temperature of 28°C and a shaking speed of 180rpm, select rotten white fungus and shake it in the culture medium, then dilute the shaken culture medium by more than one dilution Apply to each component and its concentration is: tremella polysaccharide 10g / L, agarose 6g / L, peptone 3g / L, yeast powder 0.5g / L, iron phosphate 0.01g / L, and the solvent is tap water, the mixed solution pH = 7.4, sterilize at 121°C for 20 minutes on the plate of the screening medium, make more than three parallel samples for each dilution, and culture the plate upside dow...

Embodiment 3

[0053] The preparation method of tremella oligosaccharide in the present embodiment, concrete steps are as follows:

[0054] Step 1, strain screening and cultivation, preparation of each component and its concentration are: tremella polysaccharide 3g / L, peptone 8g / L, yeast powder 2.5g / L, iron phosphate 0.02g / L, and the solvent is tap water, the mixed solution pH = 7.4, sterilized at 121°C for 20 minutes in the culture medium, at a temperature of 28°C and a shaking speed of 180rpm, select rotten white fungus and shake it in the culture medium, then dilute the shaken culture medium by more than one dilution Apply to each component and its concentration is: tremella polysaccharide 20g / L, agarose 9g / L, peptone 8g / L, yeast powder 2.5g / L, iron phosphate 0.02g / L, and the solvent is tap water, the mixed solution pH = 7.4, sterilize at 121°C for 20 minutes on the plate of the screening medium, make more than three parallel samples for each dilution, and culture the plate upside down at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com