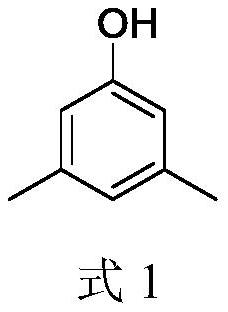

Production method of 3, 5-dimethylphenol and pressure-controlled production device used in production method

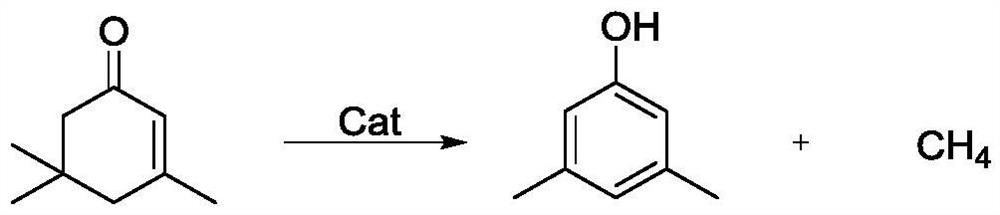

A technology of dimethylphenol and production equipment, which is applied in the production of bulk chemicals, chemical instruments and methods, and the preparation of organic compounds, and can solve the problem of 3,5-dimethylphenol selectivity decline, conversion rate and selectivity Low, high equipment requirements, etc., to achieve the effect of improving selectivity and conversion, low reaction temperature, and high reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

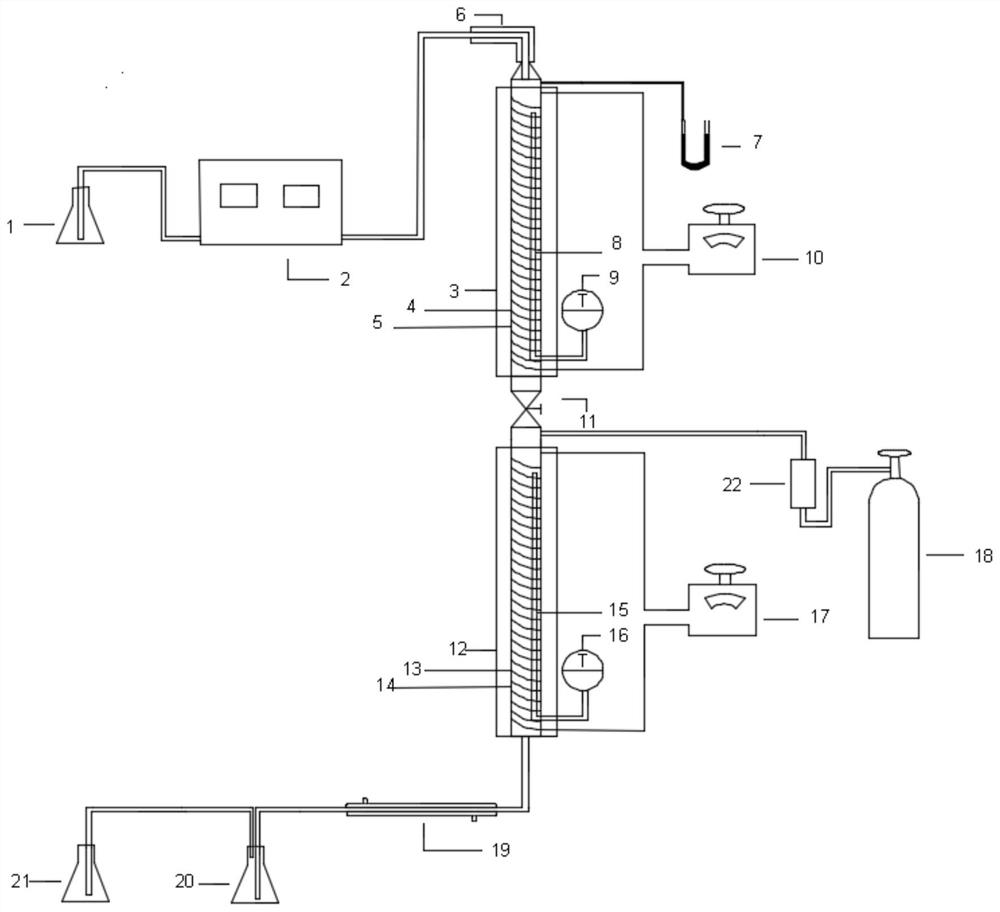

[0040] Device Example 1, a pressure-controlled production device, which is a cracking reactor, includes a raw material container 1, a sampling pump 2, a reaction tube I5 with a heating device and a pressure gauge 7, a reaction tube II14 with a heating device, and a Heat pipe 6, the gas bottle 18 that is used to dress inert gas.

[0041] Reaction tube I5 is the upper half tubular reactor, and reaction tube II14 is the lower half tubular reactor.

[0042] The heating device of reaction tube I5 is composed of heating wire I4, temperature measuring tube I8, thermocouple I9, and voltage regulator box I10; heating wire I4 and temperature measuring tube I8 are located in the inner cavity of reaction tube I5, and thermocouple I9 and voltage regulator The box I10 is located on the periphery of the reaction tube I5; the regulator box I10 is electrically connected with the heating wire I4 to realize the adjustment of the temperature in the reaction tube I5; the temperature measuring tube...

Embodiment 1

[0058] Embodiment 1, the production method of the 3,5-xylenol that utilizes the pressure-controlling type production device described in device example 1 to carry out:

[0059] (1) Weigh 100g of isophorone and add 0.8g of 1,2-dibromoethane. After mixing, add the resulting mixture into raw material container 1. When the temperature of reaction tube I5 rises to 470°C and reaction tube II14 rises to 510°C, The mixture is fed to the reaction tube I5 under the control of the injection pump 2, and the feed rate is 4ml / min;

[0060] Set the temperature of the preheating tube 6 to 400-450°C, so that the mixture is vaporized, and the gasified mixture enters the reaction tube I5;

[0061] Adjust the size of the pressure control valve 11, observe the change in the height of the mercury column of the U-shaped tube manometer 7, and control the height difference of the mercury column to be about 23 cm (the pressure of the reaction tube I5 is 0.3 atm). Adjust the size of the valve of the ga...

Embodiment 2~ Embodiment 9

[0068] Change the catalyst consumption in embodiment 1, feed rate, reaction pressure and reaction temperature of upper stage reactor (reaction tube I5), all the other steps are equal to embodiment 1 (nitrogen flow remains constant), obtain following embodiment respectively, obtained The conversion of isophorone and the selectivity of MX are shown in Table 1 below.

[0069] Table 1

[0070]

[0071] Explanation: In Example 4, the residence time of the material in the reaction tube I5 and the reaction tube II14 is about 35s and 15s respectively; in Example 5, the residence time of the material in the reaction tube I5 and the reaction tube II14 is about 30s and 10s respectively.

[0072] Embodiment 10~Example 11, change the reaction temperature of the second half section reactor (reaction tube II14) in the embodiment 1, all the other steps are equal to embodiment 1, obtain the following examples respectively, the conversion ratio of gained isophorone and The selectivity of MX...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com