Antibacterial and antistatic edge band and preparation method thereof

An edge banding and antistatic technology, applied in the field of composite materials, can solve the problems affecting the appearance and quality of PVC edge banding, low water content, poor conductivity, etc., and achieve the effect of avoiding adsorption on the surface of the edge banding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

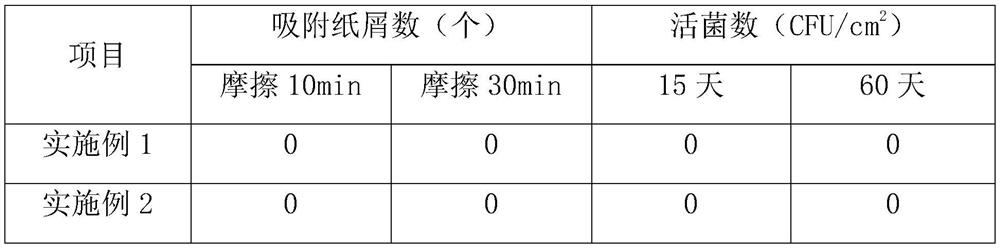

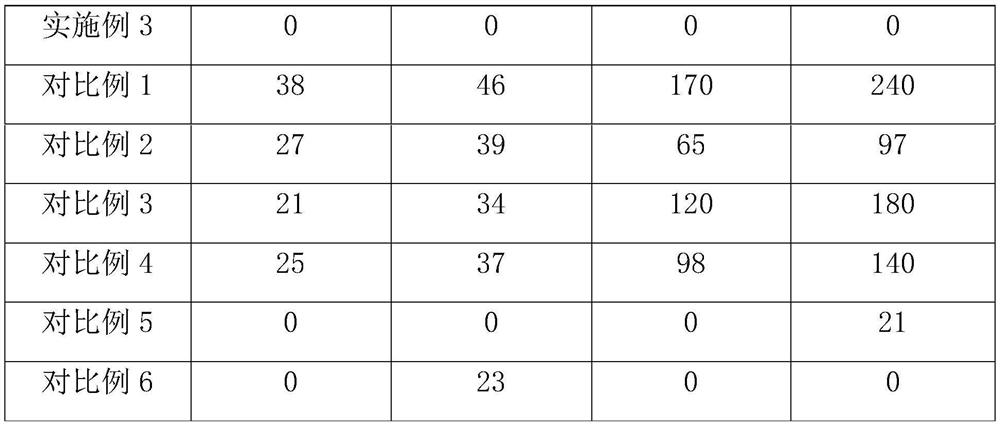

Examples

preparation example Construction

[0050] Preparation example of nano liposome dispersion

[0051] Chitosan quaternary ammonium salt in the following raw materials was purchased from Hangzhou Linran Biotechnology Co., Ltd., item number 1029019201; sodium lauryl sulfate was purchased from Shanghai Jingyi Chemical Technology Co., Ltd., model K12; glyceryl monostearate was purchased from Weifang Shengbaolong Technology Co., Ltd.; vegetable oleic acid was purchased from coconut oleic acid produced by Guangzhou Runquan Chemical Co., Ltd.; Tween 80 was purchased from Zhengzhou Wanbo Chemical Products Co., Ltd., model T-80; methanol is 99.9% anhydrous methanol .

preparation example 1

[0052] Preparation example 1: Nano liposome dispersion is prepared by the following method:

[0053] S11. Weigh 0.8 kg of chitosan quaternary ammonium salt, 0.32 kg of sodium lauryl sulfate, 6.4 kg of glycerol monostearate, 0.8 kg of oleic acid, 800.48 kg of Tween, 136 kg of methanol, and 47.2 kg of water; For vegetable oleic acid;

[0054] S12, dissolving chitosan quaternary ammonium salt, glyceryl monostearate, and oleic acid in methanol liquid at 65 degrees Celsius to obtain an oil phase; dissolving sodium lauryl sulfate and Tween 80 in In water, heated to 65 degrees Celsius to obtain an aqueous phase;

[0055] S13, slowly inject the oil phase prepared in S12 into the water phase under the high-speed homogenization condition of 2100r / min, homogenize for 25min, and then stir for 25min under the magnetic stirring effect of 1500r / min to obtain a translucent nanoemulsion;

[0056] S14. Disperse the translucent nanoemulsion prepared in S13 into water at 8 degrees Celsius at a ...

preparation example 2

[0057] Preparation example 2: Nano liposome dispersion is prepared by the following method:

[0058] S11. Weigh 0.5kg of chitosan quaternary ammonium salt, 0.2kg of sodium lauryl sulfate, 4kg of glyceryl monostearate, 0.5kg of oleic acid, 800.3kg of Tween, 85kg of methanol, and 29.5kg of water; vegetable oleic acid;

[0059] S12, dissolving chitosan quaternary ammonium salt, glyceryl monostearate, and oleic acid in methanol liquid at 60 degrees Celsius to obtain an oil phase; dissolving sodium lauryl sulfate and Tween 80 in In water, heated to 60 degrees Celsius to obtain an aqueous phase;

[0060] S13, the oil phase prepared in S12 is slowly injected into the water phase under the high-speed homogenization condition of 1800r / min, homogenized for 20min, and then stirred for 25min under the magnetic stirring effect of 1500r / min to obtain a translucent nanoemulsion;

[0061] S14. Disperse the translucent nanoemulsion prepared in S13 into water at 4 degrees Celsius at a stirrin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com