Corrosion-resistant graphene conductive coating on metal surface and preparation method thereof

A conductive coating and metal surface technology, which is applied in the field of graphene corrosion-resistant conductive coating and its preparation, can solve problems such as graphene derivative agglomeration, and achieve the effects of improving corrosion resistance, conductivity, and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

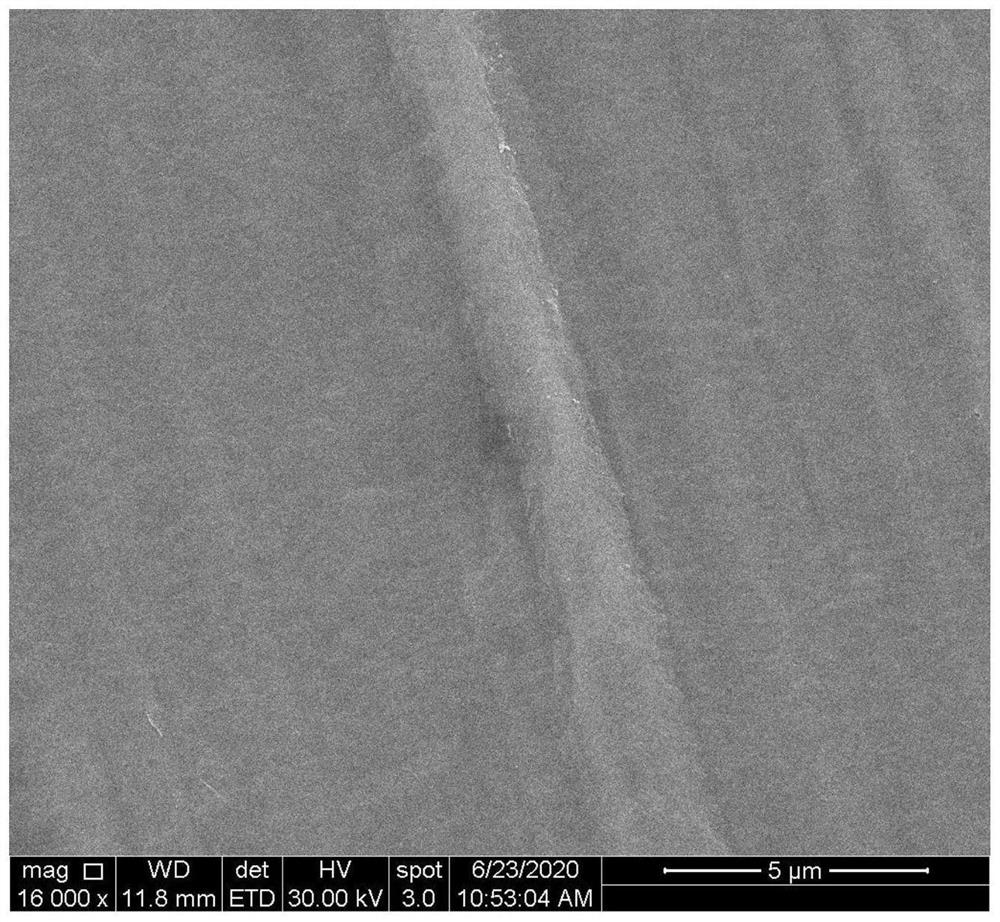

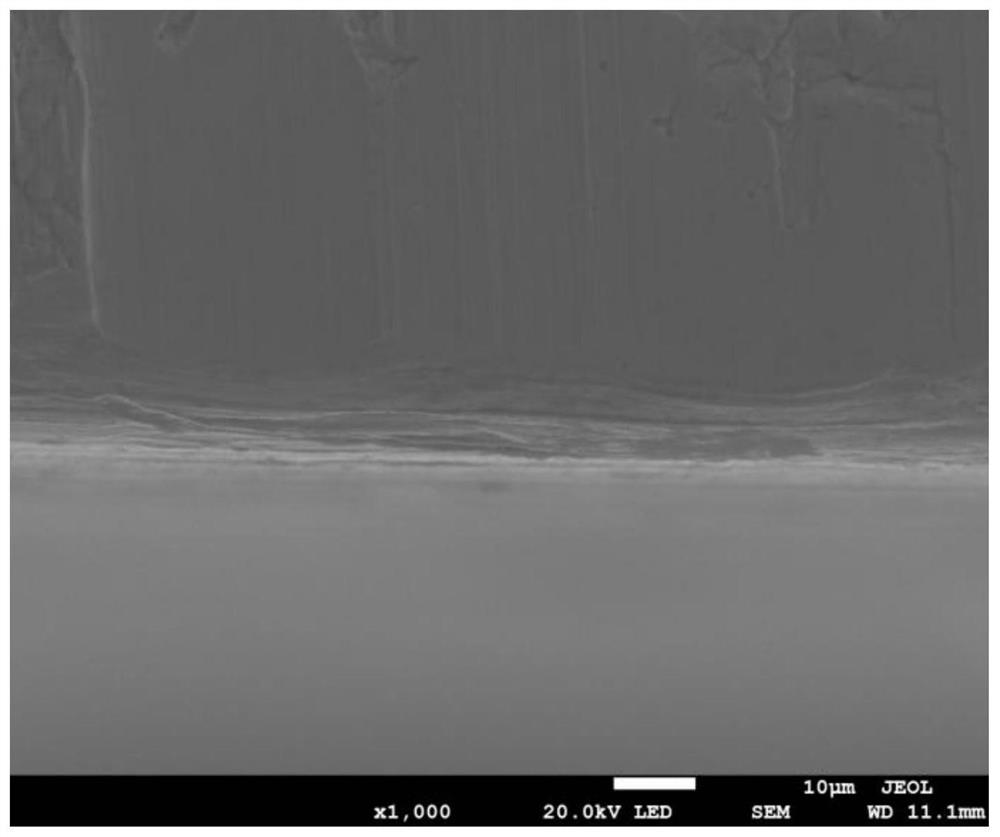

[0019] refer to Figure 1-2 , a graphene corrosion-resistant conductive coating for metal surfaces and a preparation method thereof, comprising:

[0020] A metal substrate, a coating skeleton parallel to the metal substrate, a chemical corrosion inhibitor arranged on the coating skeleton and a modifier for chemical modification of the coating skeleton, the coating skeleton is parallel Graphene aligned on the metal substrate can provide electronic pathways and a barrier to corrosive media.

[0021] Further, the chemical corrosion inhibitor is a soluble salt, including one or more of ammonium fluorozirconate, ammonium zirconium carbonate, ammonium phosphate, ammonium fluorotitanate, ammonium metavanadate, which can further enhance the corrosion resistance of the coating. corrosion.

[0022] Further, the modifier includes silane coupling agent modification, titanate coupling agent modification, benzenesulfonic acid modification and polyether ammonia modification, and the modifi...

Embodiment 1

[0030] Step 1: Using 500 mg graphene oxide as a precursor, introduce 184 mg p-aminobenzenesulfonic acid for sulfonation modification, improve the water dispersibility of graphene, and finally obtain a 4 mg / mL sulfonated graphene oxide aqueous dispersion;

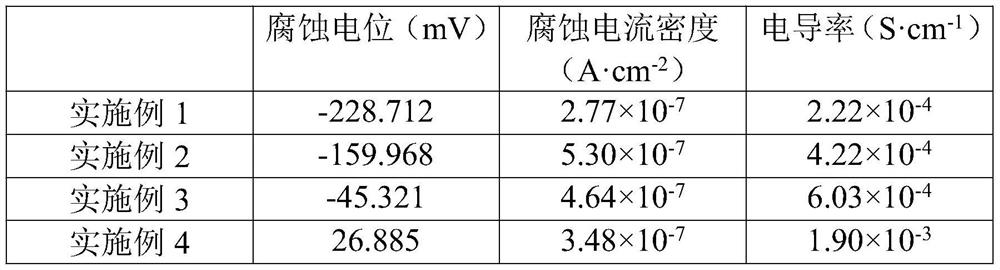

[0031] Step 2: Mix the obtained modified graphene aqueous dispersion with the inorganic corrosion inhibitor ammonium zirconium carbonate at a mass ratio of 2:1, and ultrasonically disperse for 10 minutes to prepare a concentration of 0.1mol L -1 sedimentation fluid. The metal substrate is used as the anode, and the platinum sheet is used as the cathode. After the electric field of 20V is applied for 5 minutes, the modified graphene and the soluble corrosion inhibitor in the electrolyte are deposited on the surface of the metal substrate together, and after drying, an aligned graphene is formed. etch the conductive coating. The corrosion current density of the prepared orientation-aligned graphene corrosion-resistant conduct...

Embodiment 2

[0035] Step 1: Using 500 mg graphene oxide as a precursor, introduce 184 mg p-aminobenzenesulfonic acid for sulfonation modification, improve the water dispersibility of graphene, and finally obtain a 4 mg / mL sulfonated graphene oxide aqueous dispersion;

[0036] Step 2: Mix the obtained modified graphene aqueous dispersion with the inorganic corrosion inhibitor ammonium zirconium carbonate at a mass ratio of 4:1, and ultrasonically disperse for 10 minutes to prepare a concentration of 0.5mol L -1 sedimentation fluid. The metal substrate is used as the anode, and the platinum sheet is used as the cathode. After 15 minutes under the action of an electric field of 20V, the modified graphene and the soluble corrosion inhibitor in the electrolyte are co-deposited on the surface of the metal substrate, and the aligned graphene is formed after drying. Corrosion-resistant conductive coating. The corrosion current density of the prepared orientation-aligned graphene corrosion-resista...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Corrosion current density | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Corrosion current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com