A method for high production of short-chain fatty acids using microbial symbiotic fermentation technology

A short-chain fatty acid, symbiotic fermentation technology, applied in the field of microorganisms, can solve problems such as difficult application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

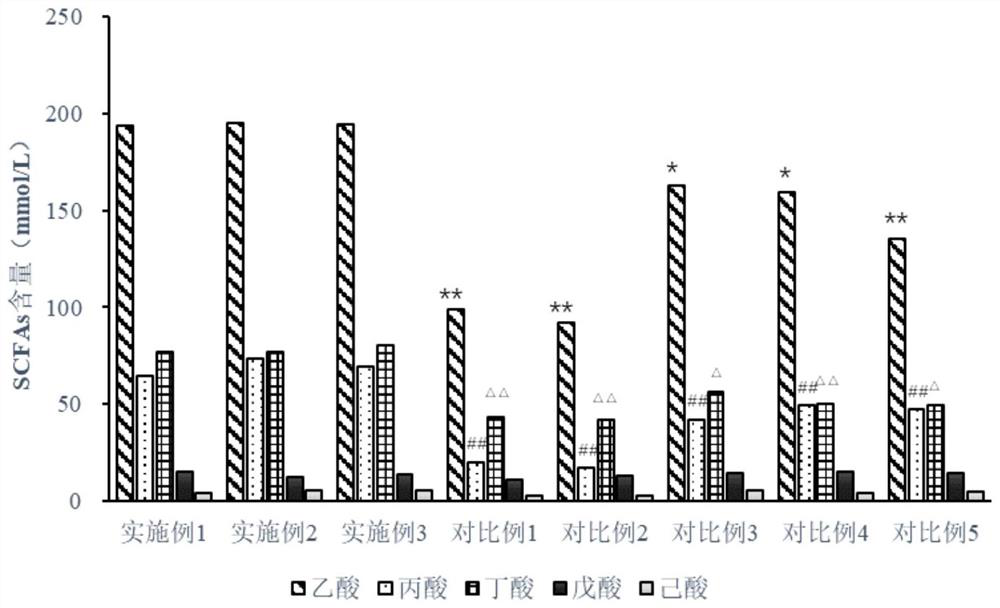

Examples

Embodiment 1

[0033] A method for high-yielding short-chain fatty acids using microbial symbiotic fermentation technology, comprising the following steps:

[0034] 1) Jerusalem artichoke pretreatment: wash 50kg of fresh Jerusalem artichoke, after the water on the surface is naturally dried, put it into a beater for beating, beat at 20Hz for 10 minutes, and obtain Jerusalem artichoke pulp;

[0035] 2) Seaweed pretreatment: Wash 50kg of seaweed, and after the moisture on the surface dries naturally, cut it into 2-5cm long and 2-5cm wide blocks, and dry it in a blast drying oven (70°C) until the water content is 10%, placed in a grinder to grind to 60 mesh, and sieved to obtain seaweed powder;

[0036] 3) Preparation of fermented pulp medium: take 10 kg of Jerusalem artichoke pulp prepared in step 1), 2 kg of seaweed powder prepared in step 2), and 0.1 kg of sodium glutamate, disperse in 87.9 kg of water, mix, and homogenize under a pressure of 20 MPa for 8 minutes , adjust the pH to 6, keep it...

Embodiment 2

[0040] A method for high-yielding short-chain fatty acids using microbial symbiotic fermentation technology, comprising the following steps:

[0041] 1) Jerusalem artichoke pretreatment: wash 50kg of fresh Jerusalem artichoke, after the water on the surface is naturally dried, put it into a beater for beating, beat at 20Hz for 10 minutes, and obtain Jerusalem artichoke pulp;

[0042] 2) Seaweed pretreatment: Wash 50kg of seaweed, and after the moisture on the surface is naturally dried, cut it into 2-5cm long and 2-5cm wide blocks, and dry it in a blast drying oven (70°C) until the moisture content is 10%, placed in a grinder to grind to 60 mesh, and sieved to obtain seaweed powder;

[0043] 3) Preparation of fermented pulp medium: take 20 kg of Jerusalem artichoke pulp prepared in step 1), 5 kg of seaweed powder prepared in step 2), and 0.5 kg of sodium glutamate, disperse in 74.5 kg of water, mix, and homogenize under a pressure of 20 MPa for 8 minutes , adjust the pH to 7,...

Embodiment 3

[0047] A method for high-yielding short-chain fatty acids using microbial symbiotic fermentation technology, comprising the following steps:

[0048] 1) Jerusalem artichoke pretreatment: wash 50kg of fresh Jerusalem artichoke, after the water on the surface is naturally dried, put it into a beater for beating, beat at 20Hz for 10 minutes, and obtain Jerusalem artichoke pulp;

[0049] 2) Seaweed pretreatment: Wash 50kg of seaweed, and after the moisture on the surface is naturally dried, cut it into 2-5cm long and 2-5cm wide blocks, and dry it in a blast drying oven (70°C) until the moisture content is 10%, placed in a grinder to grind to 60 mesh, and sieved to obtain seaweed powder;

[0050] 3) Preparation of fermented pulp culture medium: 40 kg of Jerusalem artichoke pulp prepared in step 1), 10 kg of seaweed powder prepared in step 2), and 1 kg of sodium glutamate were dispersed in 49 kg of water, mixed, homogenized under a pressure of 20 MPa for 8 min, and adjusted The pH ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com