A super anti-dispersion, anti-segregation concrete and its preparation method and construction technology

A concrete and anti-segregation technology, which is applied to the processing of building materials, construction, building construction, etc., can solve the problems of adverse effects on the anti-cracking performance of pumped concrete, the decrease of the viscosity of pumped concrete, and the impact on the uniformity of concrete, so as to improve Anti-segregation performance, improve thixotropy, and prevent heavy components from settling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

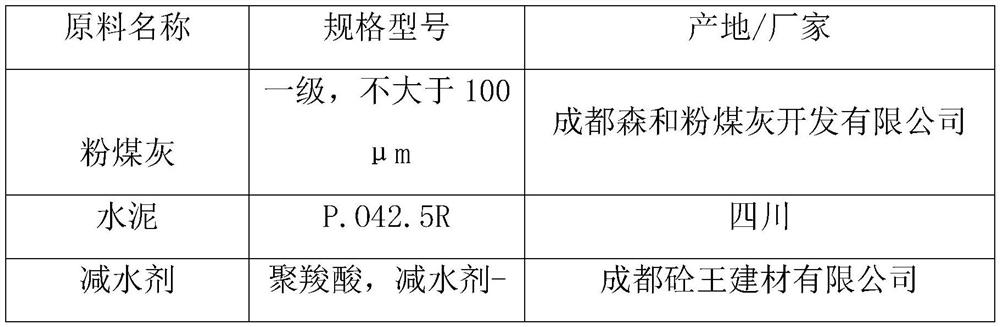

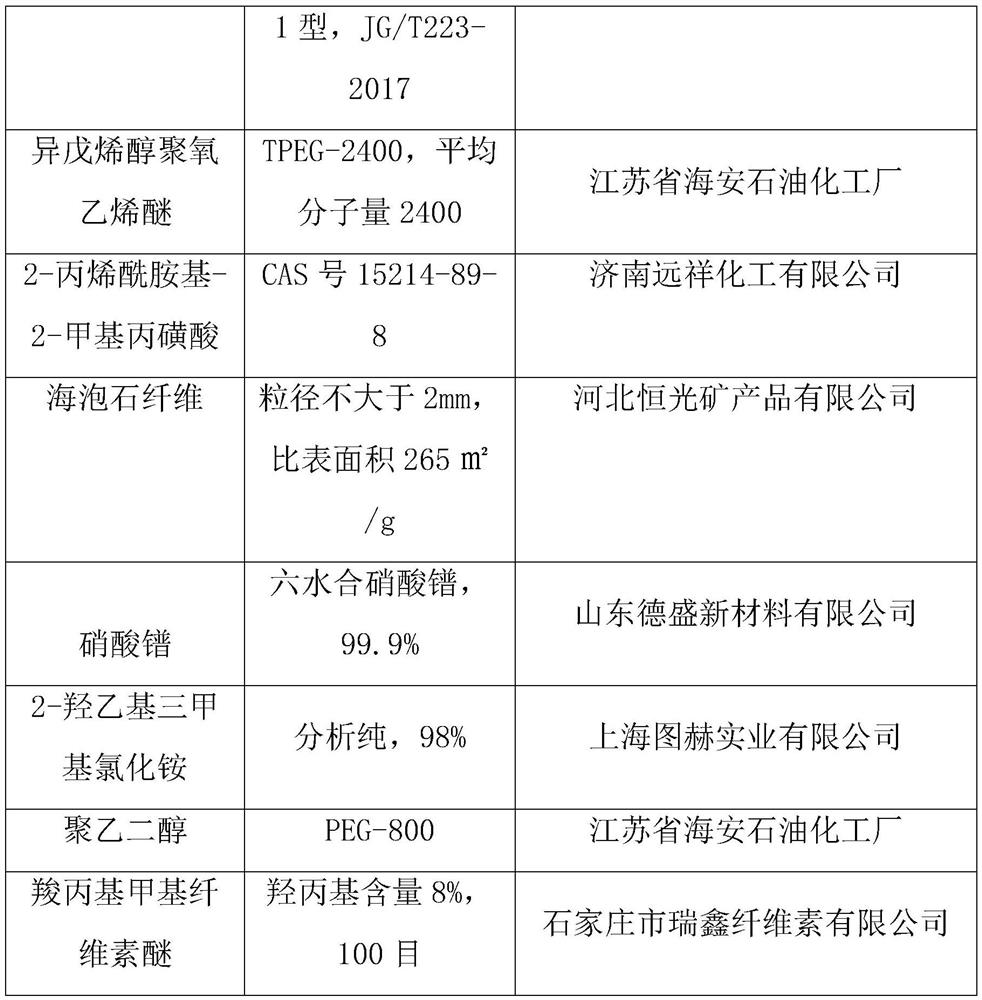

Method used

Image

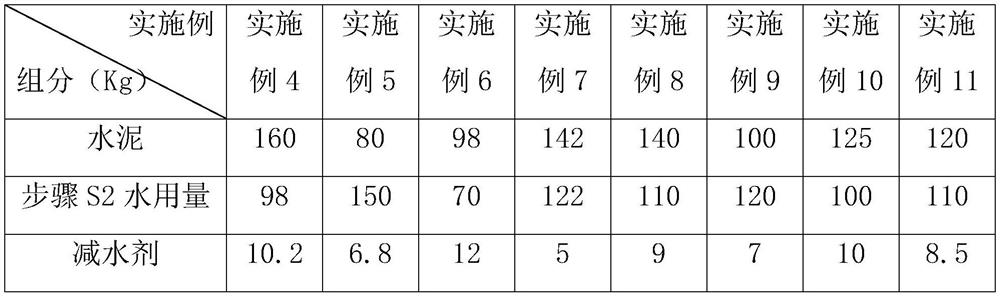

Examples

Embodiment 1

[0040] Embodiment 1: a kind of preparation method of super anti-dispersion, anti-segregation concrete, comprises the steps:

[0041] Take 0.55kg of praseodymium nitrate, add water to prepare a praseodymium nitrate aqueous solution with a mass concentration of 4%, add 2.5kg of sepiolite fibers, stir at a speed of 100 rpm, heat to 75°C for 240min, filter, and complete the praseodymium modification. Prepare praseodymium-modified sepiolite fiber; get 1kg of 2-hydroxyethyltrimethylammonium chloride, add water to prepare a 2-hydroxyethyltrimethylammonium chloride aqueous solution with a mass concentration of 6%, add praseodymium modified The permanent sepiolite fiber was stirred at a speed of 100 rpm, heated to 75°C for 200 minutes, filtered, and the filter cake was dried at 100°C for 180 minutes to complete the organic modification and obtain the modified sepiolite fiber.

[0042] S1 Mixing: Weigh 160kg of gravel, add 300kg of sand, 185kg of fly ash, 2.2kg of polyethylene glycol an...

Embodiment 2

[0045] The difference between embodiment 2 and embodiment 1 is that no polyethylene glycol is added in embodiment 2, and the others are consistent with embodiment 1.

Embodiment 3

[0047] The difference between embodiment 3 and embodiment 1 is that no carboxypropyl methyl cellulose ether is added in embodiment 3, and the others are consistent with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com