Polyoxyethylene-based ionic conduction type propellant and preparation method thereof

A polyethylene oxide, ion-conducting technology, used in offensive equipment, explosives processing equipment, explosives, etc., to achieve high energy density, reduce agglomeration, and improve combustion efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The preparation method comprises the following steps:

[0032] S1. A certain amount of plasticizer (such as ethylene carbonate crystals) is added to a certain amount of solvent (concentration is 40mg / ml), magnetically stirred at room temperature until it dissolves completely (usually 20-30 minutes), and the plasticizer is obtained. plasticizer solution;

[0033] S2. A certain amount of buffer solution (Tris solution) is added to a certain amount of distilled water (usually the concentration is 1-3mg / mL), adding dilute hydrochloric acid to adjust the pH value between 8-8.5, adding dopamine and stirring for a period of time (usually 5-15 minutes), dopamine is partially polymerized, the solution turns brown, then aluminum powder is added and stirred, so that dopamine is polymerized in situ on the surface of the aluminum powder to form a polydopamine layer, filtered and dried to obtain polydopamine-coated aluminum powder;

[0034] S3. Dissolving a certain amount of polyeth...

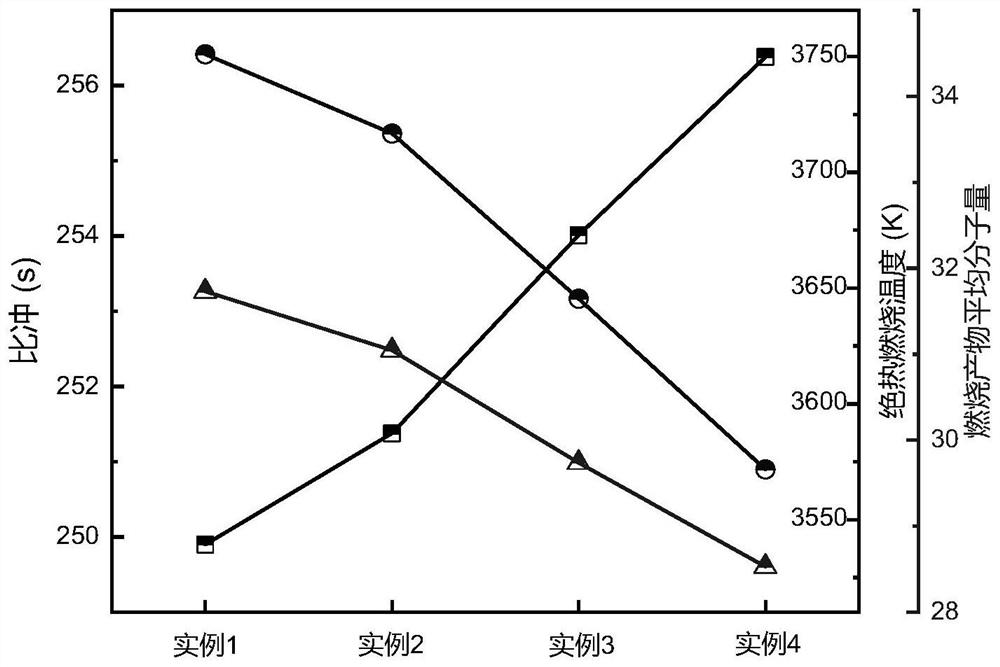

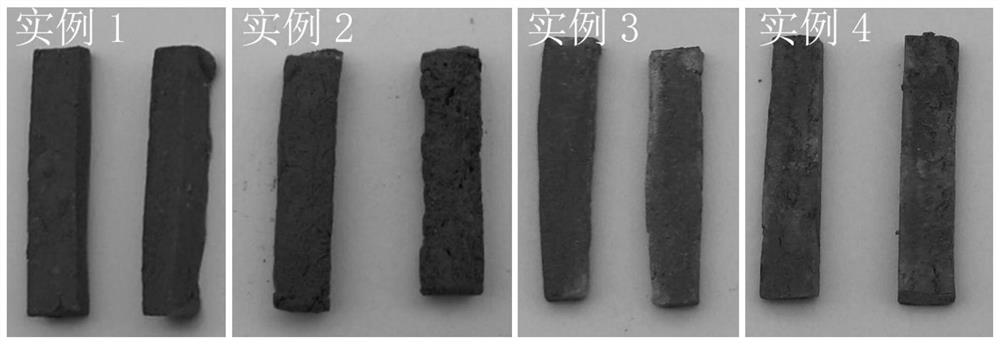

example 1

[0040] A polyoxyethylene-based ion-conductive propellant and a preparation method thereof, comprising the following process steps:

[0041] (1) Preparation of plasticizer solution: 200 mg of ethylene carbonate crystals were weighed, dissolved in 5 ml of absolute ethanol, and magnetically stirred at room temperature for 20 minutes to obtain a plasticizer solution.

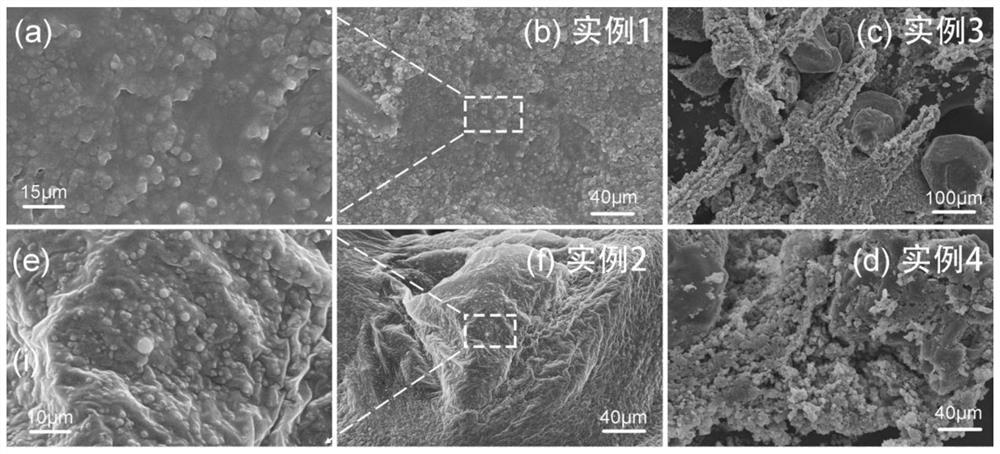

[0042] (2) Preparation of surface-coated polydopamine aluminum powder: Add 0.30 g of dopamine and 0.18 g of Tris buffer solution (pH=8.5) into 150 ml of distilled water, stir until the dopamine molecules partially polymerize (the color turns brown), and then add 2.0 g of micron aluminum powder (1-2 μm) was stirred for 4 hours to in-situ polymerize polydopamine on the surface of the aluminum powder to form a polydopamine layer, and the mixture was taken out, centrifuged and freeze-dried to obtain an aluminum powder whose surface was evenly coated with polydopamine.

[0043] (3) Preparation of polymer matrix: Weigh 90...

example 2

[0053] A polyoxyethylene-based ion-conductive propellant and a preparation method thereof, comprising the following process steps:

[0054] (1) Preparation of plasticizer solution: 200 mg of ethylene carbonate crystals were weighed, dissolved in 5 ml of absolute ethanol, and magnetically stirred at room temperature for 20 minutes to obtain a plasticizer solution.

[0055] (2) Preparation of surface-coated polydopamine aluminum powder: Add 0.30 g of dopamine and 0.18 g of Tris buffer solution (pH=8.5) into 150 ml of distilled water, stir until the dopamine molecules partially polymerize (the color turns brown), and then add 2.0 g of micron aluminum powder (1-2 μm) was stirred for 4 hours to in-situ polymerize polydopamine on the surface of the aluminum powder to form a polydopamine layer, and the mixture was taken out, centrifuged and freeze-dried to obtain an aluminum powder whose surface was evenly coated with polydopamine.

[0056] (3) Preparation of polymer matrix: Weigh 90...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com