Coal gangue-based porous composite material as well as preparation method and application thereof

A technology of porous composite materials and coal gangue, applied in the field of materials, can solve the problems of inability to adsorb heavy metals, etc., achieve excellent adsorption capacity, strong chelation performance, and reduce the effect of impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

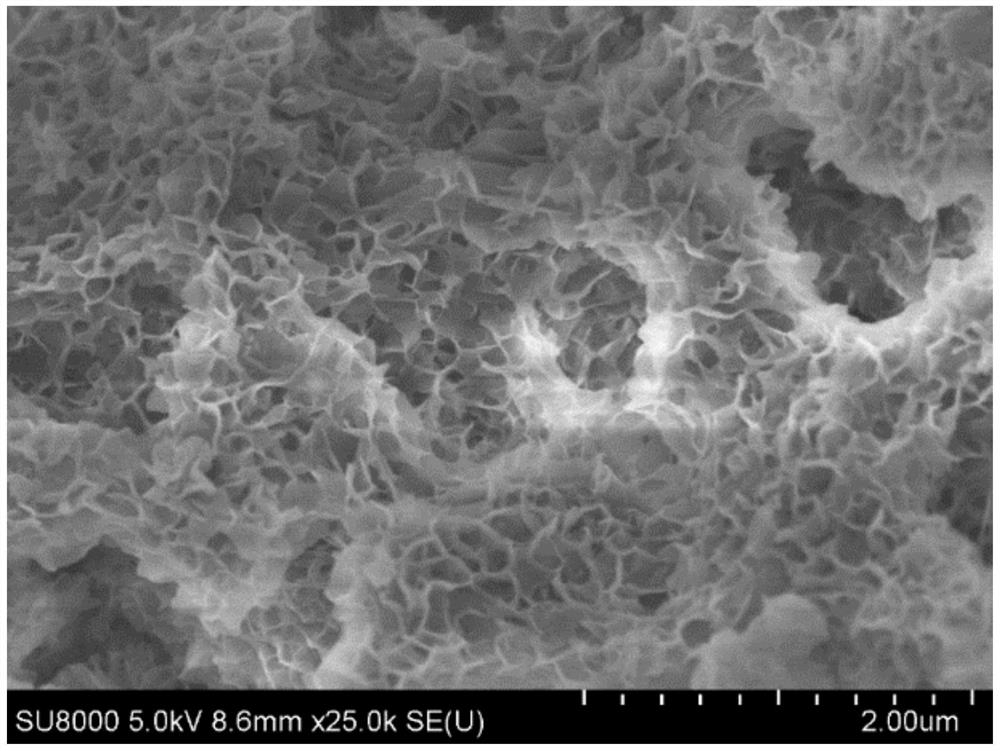

Image

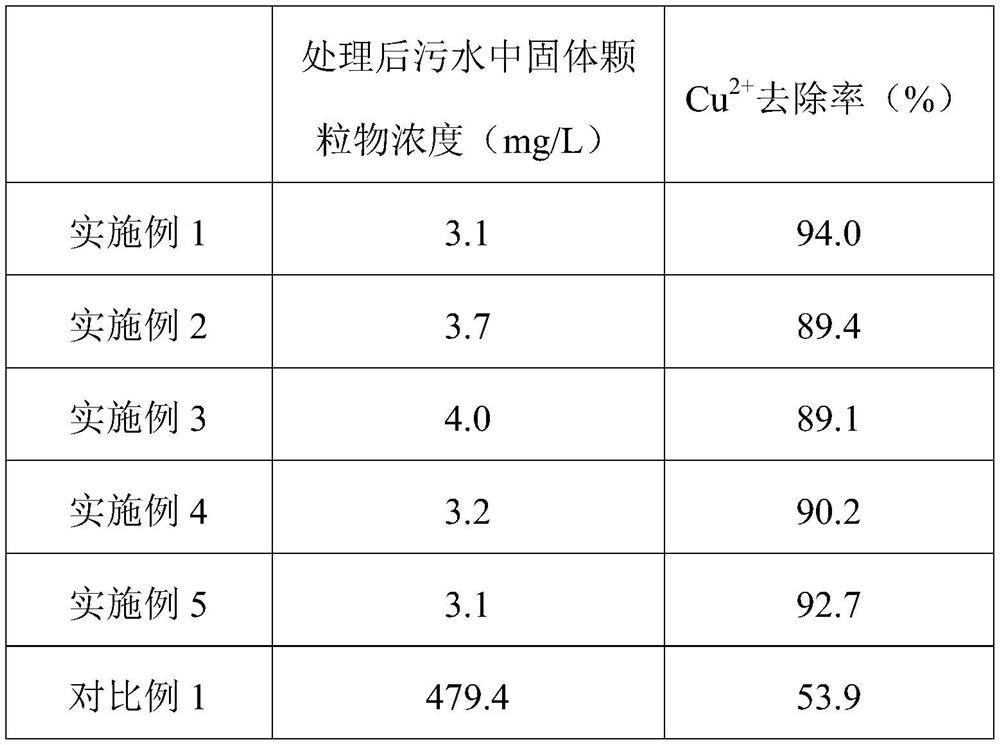

Examples

Embodiment 1

[0088] This embodiment provides a coal gangue-based porous composite material, the preparation method of which is as follows:

[0089] (1) Take coal gangue, after preliminary mechanical crushing and further 6h of 350rpm ball milling, to obtain coal gangue fine powder with an average particle size of 1.6μm (D90 is 2.4μm); after heat treatment at 600°C for 4h, take it out at 25°C Leave to cool.

[0090] (2) the coal gangue fine powder that step (1) obtains and the massfraction that accounts for slurry quality are 0.03% sodium dodecylbenzene sulfonate, 0.8% polyurethane, 0.5% hydrophilic modified nano-carbon, 3% aluminum sol was ball milled with an appropriate amount of water, and the slurry was taken out after 1 hour, further stirred by high-speed mechanical stirring at 1100 rpm for 15 minutes to foam, then injected into a mold, and dried at 40°C for 10 hours.

[0091] After demoulding, the green body was heated up to 1100°C under an air atmosphere program and held for 2 hours ...

Embodiment 2

[0095] This embodiment provides a coal gangue-based porous composite material, the preparation method of which is as follows:

[0096] (1) Take coal gangue, after preliminary mechanical crushing and further 8h of 300rpm ball milling, to obtain coal gangue fine powder with an average particle size of 0.1μm (D90 is 2.4μm); after heat treatment at 500°C for 10h, take it out at 25°C Leave to cool.

[0097] (2) the coal gangue fine powder that step (1) obtains and the mass fraction that accounts for slurry mass are 0.01% sodium lauryl sulfate, 2% polyurethane, 0.1% hydrophilic modified nano-carbon, 6% The aluminum sol was ball-milled with an appropriate amount of water, and the slurry was taken out after 1 hour, further stirred by high-speed mechanical stirring at 600 rpm for 30 minutes to foam, then injected into a mold, and dried at 15°C for 30 hours.

[0098] After demoulding, the green body was heated up to 500°C under an air atmosphere program and kept for 4 hours to obtain a...

Embodiment 3

[0102] This embodiment provides a coal gangue-based porous composite material, the preparation method of which is as follows:

[0103] (1) Take coal gangue, after preliminary mechanical crushing and further 4h of 400rpm ball milling, to obtain coal gangue fine powder with an average particle size of 10μm (D90 is 2.4μm); after heat treatment at 700°C for 2h, take it out at 25°C cool down.

[0104] (2) the coal gangue fine powder that step (1) obtains and the mass fraction that accounts for slurry mass are 0.05% sodium cetyl sulfate, 0.04% polyurethane, 0.8% hydrophilic modified nano-carbon, 1% The aluminum sol was ball-milled with an appropriate amount of water, and the slurry was taken out after 1 hour, further stirred by high-speed mechanical stirring at 400 rpm for 5 minutes to foam, then injected into a mold, and dried at 60°C for 4 hours.

[0105] After demoulding, the green body was heated up to 1400°C in an air atmosphere and kept for 1 hour to obtain a gangue-based por...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average particle size | aaaaa | aaaaa |

| Average particle size | aaaaa | aaaaa |

| Average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com