Multiphase nanocomposite material and its preparation method, nitro group reduction catalyst, application

A nanocomposite material, cobalt nitrate hexahydrate technology, applied in the field of materials, to achieve the effects of strong controllability, simple and green process, and good reduction catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The embodiment of the present invention also provides a method for preparing a multiphase nanocomposite material. The method for preparing a multiphase nanocomposite material includes the following steps:

[0035] Weigh cobalt nitrate hexahydrate, nickel nitrate hexahydrate and ammonium chloride and dissolve them in deionized water and mix them evenly, then add ammonia water to adjust the pH value to 6-7, continue stirring for at least 30 minutes, then add the amorphous Continue to stir and mix the alumina powder for not less than 3 hours, then transfer the stirred and mixed mixture to a sealed environment, heat at 70-80°C for 30-40 hours, cool down naturally, wash, dry, and then protect Calcination at 450-550°C under gas purging, the heating rate of the calcination is 4-6°C per minute, the calcination time is not less than 5 hours, and the multi-phase nanocomposite material is obtained after natural cooling, that is, cobalt-nickel alloy and Amorphous alumina composite....

Embodiment 1

[0050] A kind of amorphous alumina powder, its preparation method is as follows:

[0051] Step 1: Weigh 4.66 g of aluminum sulfate octadecahydrate, 1.68 g of urea, and 0.4 g of sodium tartrate in 70 ml of deionized water, stir for at least 1 hour, transfer to a stainless steel reaction kettle, and heat in an oven at 165°C for 2 hours , after natural cooling, the obtained product was washed with deionized water and absolute ethanol, and centrifuged and dried to obtain a solid powder.

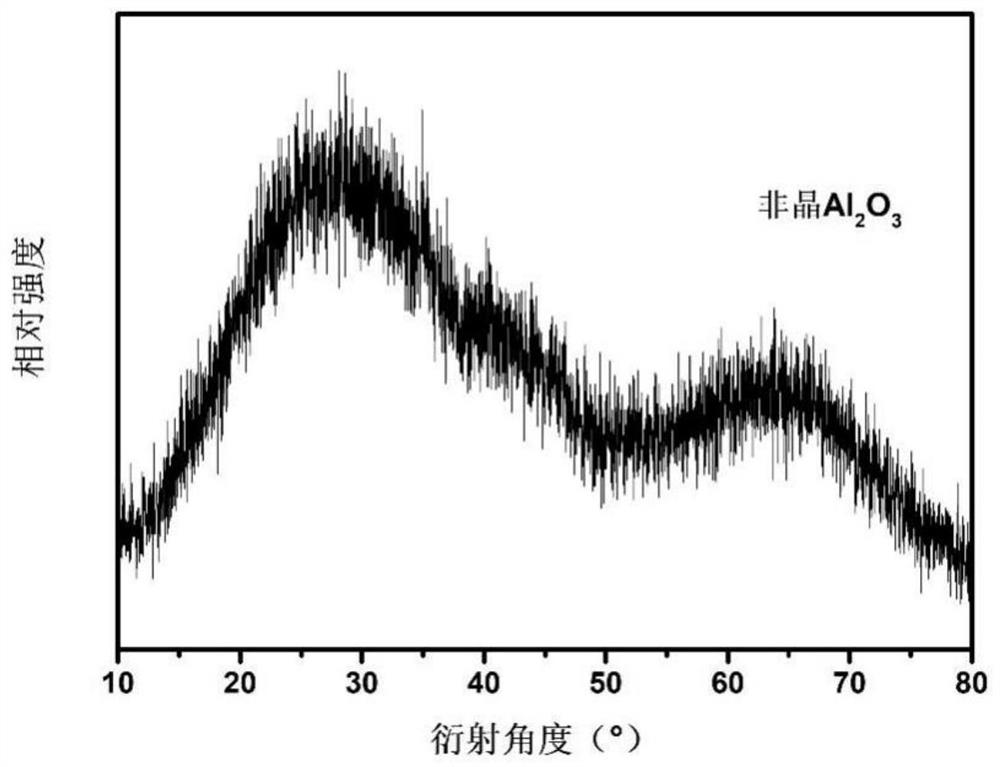

[0052] Step 2: Heat the solid powder obtained in Step 1 in a muffle furnace at a heating rate of 5°C per minute, a calcination temperature of 500°C, and a calcination time of 5 hours. Amorphous alumina powder (appearance is amorphous alumina microspheres), and its X-ray diffraction pattern is as follows figure 1 shown. allowable figure 1 The diffraction peaks of amorphous alumina are seen in the figure, which proves that the preparation is amorphous alumina.

Embodiment 2

[0054] Using the amorphous alumina powder prepared in Example 1 to prepare a composite of cobalt-nickel-aluminum hydrotalcite and amorphous alumina as a precursor, the specific steps are as follows:

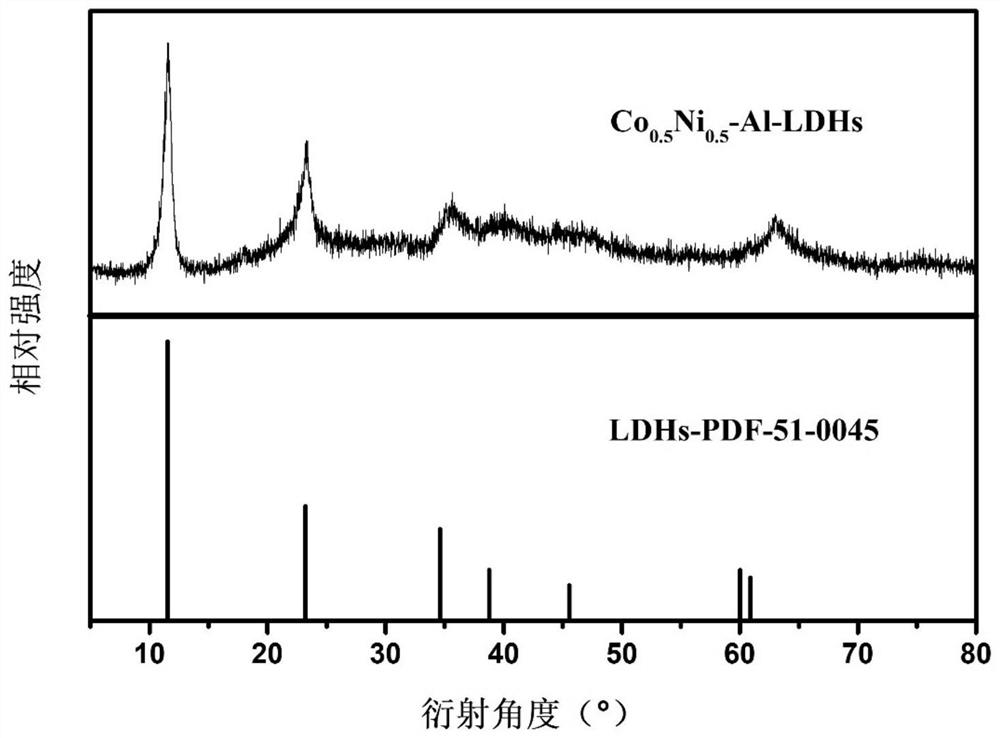

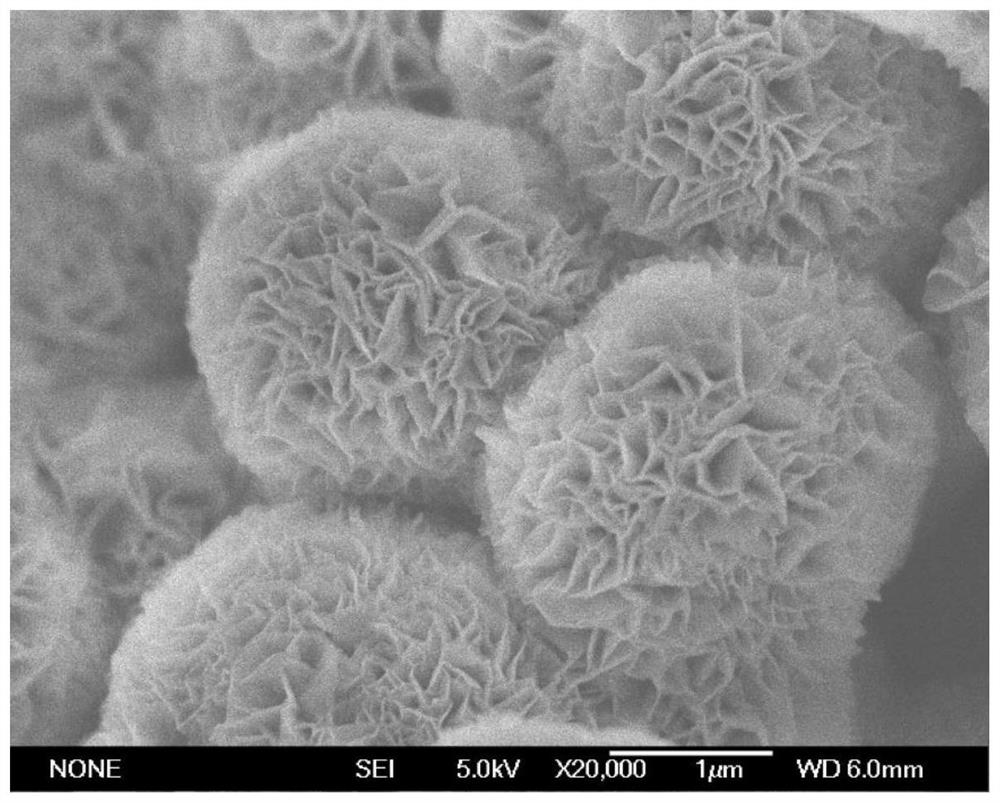

[0055] Weigh 1.16 grams of cobalt nitrate hexahydrate, 1.16 grams of nickel nitrate hexahydrate and 2.57 grams of ammonium chloride are dissolved in 80 milliliters of deionized water, stir until completely dissolved, then adjust the pH to 6.5 with a 3wt% ammonia solution, and continue stirring After at least 30 minutes, add 0.3 g of the amorphous alumina powder prepared in Example 1, continue stirring for no less than 3 hours, transfer the mixture to a stainless steel reaction kettle, heat in an oven at 75°C for 36 hours, and cool down naturally , the resulting product was washed with deionized water and absolute ethanol, and dried by centrifugation to obtain a composite of cobalt-nickel-aluminum hydrotalcite and amorphous alumina as a precursor, denoted as Co 0.5 Ni 0.5 -Al-LDH...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com