Pharmaceutical wastewater treatment process

A pharmaceutical wastewater and process technology, applied in water/sewage treatment, natural water body treatment, biological water/sewage treatment, etc., can solve problems such as non-conformity of effluent, reduction of wastewater biodegradability, difficulty in achieving treatment effects, etc., to reduce the burden Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

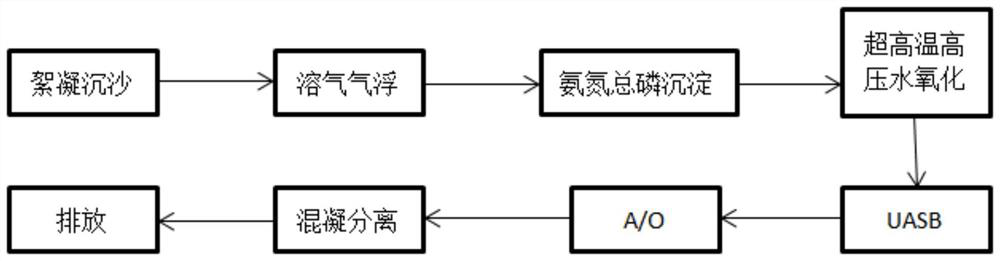

[0047] Add 200-400ppm to one cubic meter of pharmaceutical wastewater containing CODcr=2000mg / L, BOD5=1300mg / L, SS=500mg / L, TP=130mg / L, NH3-N=160mg / L, total nitrogen=400mg / L After the polyaluminum chloride (PAC) is precipitated through the grit chamber, it enters the next slag separation tank, and after adding 100-300ppm of polyoxyethylene polyoxypropylene stearyl ether, 100-300ppm of polyaluminum chloride (PAC) is added. ), remove the floating substances through the grid, and then carry out dissolved air flotation to further gather small particles and small specific gravity substances in the wastewater, and then remove them through the fine grid.

[0048] After the above treatment, add 50-60 grams of sodium hydroxide and 50-60 grams of magnesium oxide in sequence, and after precipitation and separation, add H 2 o 2 After about 20-30g / L (relative to the volume of waste water), pass it into an ultra-high temperature and high pressure water oxidation reactor, keep the temperatu...

Embodiment 2

[0051] Add 400-700ppm to one cubic meter of pharmaceutical wastewater containing CODcr=3000mg / L, BOD5=1800mg / L, SS=600mg / L, TP=150mg / L, NH3-N=180mg / L, total nitrogen=450mg / L After the polymeric ferric sulfate (PFS) is precipitated through the grit chamber, it enters the next slag separation tank. After adding 150-350ppm of nonylphenol polyether, add 100-300ppm of polymeric ferric sulfate (PFS), and remove the floating through the grid. After that, dissolved air flotation is carried out, and the small particles and small specific gravity substances in the wastewater are further collected and floated, and then removed through fine grids.

[0052] After the above treatment, add 40-65 grams of sodium hydroxide and 40-65 grams of magnesium oxide in sequence, and after precipitation and separation, add about 15-40 g / L of oxygen, Cu (NO 3 ) 2 After about 15-30mg / L (relative to the volume of wastewater), pass it into an ultra-high temperature and high pressure water oxidation reactor...

Embodiment 3

[0055] Add 300-500ppm to one cubic meter of pharmaceutical wastewater containing CODcr=4000mg / L, BOD5=2000mg / L, SS=800mg / L, TP=180mg / L, NH3-N=200mg / L, total nitrogen=500mg / L Polyaluminum chloride (PAC) and 200-400ppm polyferric sulfate (PFS) are then precipitated through the grit chamber, and then enter the next slag separation tank, where 200-400ppm of polyoxyethylene polyoxypropylene stearyl ether is added, Add 100-300ppm polymerized ferric sulfate (PFS), remove the floating substances through the grid, and then carry out dissolved air flotation, and further gather and float the small particles and small specific gravity substances in the wastewater, and then remove them through the fine grid.

[0056] After the above-mentioned treatment, 60-90 grams of sodium hydroxide and 60-90 grams of magnesium oxide were sequentially added thereto, and after precipitation and separation, O was added therein. 3 After about 20-45g / L (relative to the volume of waste water), pass it into an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com