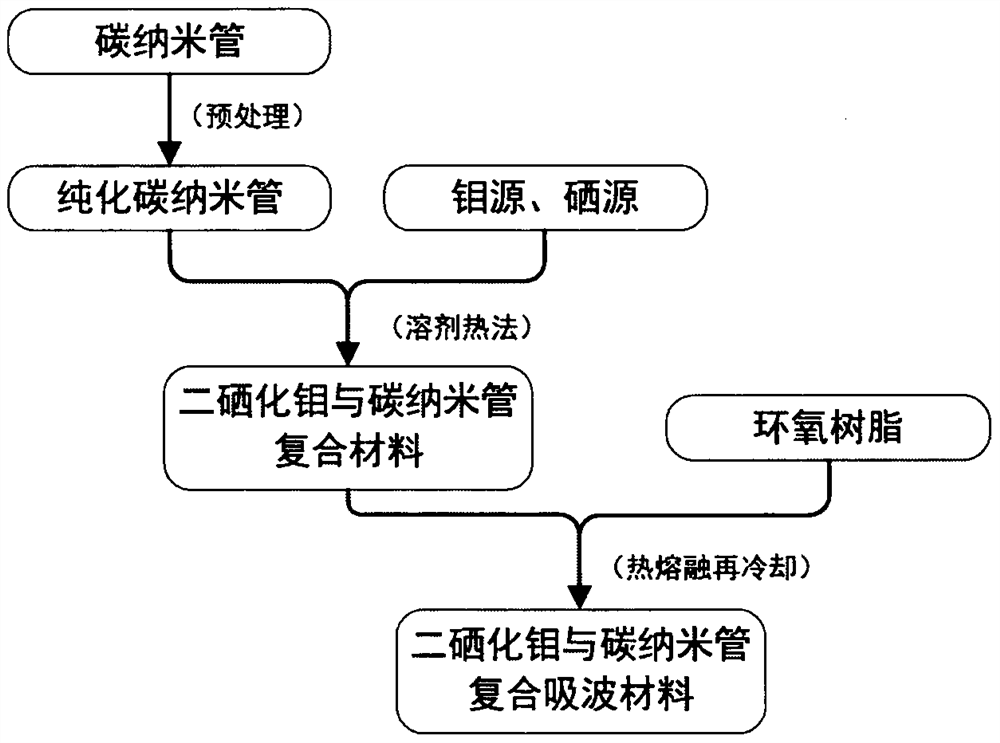

Preparation method of molybdenum diselenide and carbon nanotube composite wave-absorbing material

A carbon nanotube composite, carbon nanotube technology, applied in shielding materials, magnetic field/electric field shielding, antennas, etc., can solve the problems of low density of absorbing materials and high ferrite density, and achieve enhanced conductivity loss and The effect of polarization relaxation loss, low material density, and enhanced wave absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] After ultrasonicating the mixed solution of 100mg carbon nanotubes and 100ml dilute nitric acid (30%) for 3h, filter and wash with deionized water until the solution is neutral, dry in vacuum at 50°C for 12h to obtain purified carbon nanotubes, then 100mg purified carbon nanotubes, 0.071mmol of ammonium molybdate tetrahydrate, 1mmol of potassium selenocyanate and 100mg of polyvinylpyrrolidone were added to a mixed solution of 80ml of ultrapure water and ethylene glycol, and were fully dissolved by ultrasonic and magnetic stirring for 60min.

[0027] Transfer the mixed solution to a 100ml polytetrafluoroethylene liner, put it into a stainless steel autoclave, and react at a high temperature of 200°C for 24 hours. After the reaction, wash the black product with deionized water and absolute ethanol for 3 times to remove impurities, and then vacuum 50 and drying at ℃ for 12 hours to obtain a composite material of molybdenum diselenide and carbon nanotubes.

[0028] Heat 6g ...

Embodiment 2

[0030] 200mg of carbon nanotubes and 200ml of dilute nitric acid (30%) mixed solution was sonicated for 3h, filtered and washed with deionized water until the solution was neutral, and dried in vacuum at 60°C for 12h to obtain purified carbon nanotubes, then 200mg of purified carbon nanotubes, 0.071mmol of ammonium molybdate tetrahydrate, 1mmol of potassium selenocyanate and 120mg of polyvinylpyrrolidone were added to a mixed solution of 80ml of ultrapure water and ethylene glycol, and were fully dissolved by ultrasonic and magnetic stirring for 60min.

[0031] Transfer the mixed solution to a 100ml polytetrafluoroethylene liner, put it into a stainless steel autoclave, and react at a high temperature of 210°C for 22 hours. After the reaction, wash the black product 3 times with deionized water and absolute ethanol to remove impurities, and then vacuum 50 and drying at ℃ for 12 hours to obtain a composite material of molybdenum diselenide and carbon nanotubes.

[0032] Heat 4....

Embodiment 3

[0034] 300mg of carbon nanotubes and 300ml of dilute nitric acid (30%) mixed solution was sonicated for 4h, then filtered and washed with deionized water until the solution was neutral, dried in vacuum at 50°C for 16h to obtain purified carbon nanotubes, and then 300mg of purified carbon nanotubes, 0.143mmol of ammonium molybdate tetrahydrate, 2mmol of potassium selenocyanate and 200mg of polyvinylpyrrolidone were added to a mixed solution of 100ml of ultrapure water and ethylene glycol, and were fully dissolved by ultrasonic and magnetic stirring for 60 minutes.

[0035] Transfer the mixed solution to a 120ml polytetrafluoroethylene liner, put it into a stainless steel autoclave, and react at a high temperature of 210°C for 24 hours. After the reaction, wash the black product with deionized water and absolute ethanol for 3 times to remove impurities, and then vacuum 60 and drying at ℃ for 24 hours to obtain a composite material of molybdenum diselenide and carbon nanotubes.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com