A high wettability flame retardant electrolyte

An electrolyte and additive technology, which is applied in the field of high-wetting flame-retardant electrolyte, can solve the problems of limiting the power density of lithium batteries, increasing the internal resistance of batteries, and affecting the rate discharge performance of lithium batteries, so as to avoid adverse effects and reduce internal resistance of batteries , to meet the effect of normal charging and discharging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

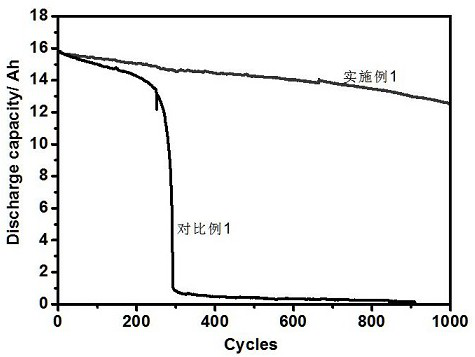

Embodiment 1

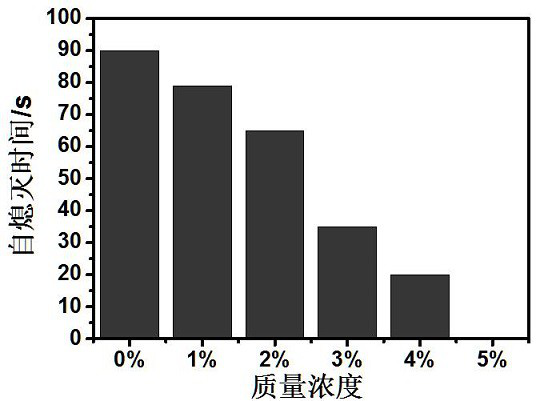

[0036] A high-wetting flame-retardant electrolyte formula, including the following raw materials by weight: ethylene carbonate 30 g, diethyl carbonate 20 g, methyl ethyl carbonate 50 g, F127 0.5 g, fluoroethylene carbonate 5 g, ethylene carbonate Vinyl ester 2 g, acetamide 3 g, ethoxypentafluorocyclotriphosphazene 5 g, lithium difluorooxalate borate 2 g, lithium bisfluorosulfonyl imide 2 g, lithium bistrifluoromethylsulfonyl imide 1g, lithium hexafluorophosphate 15g.

Embodiment 2

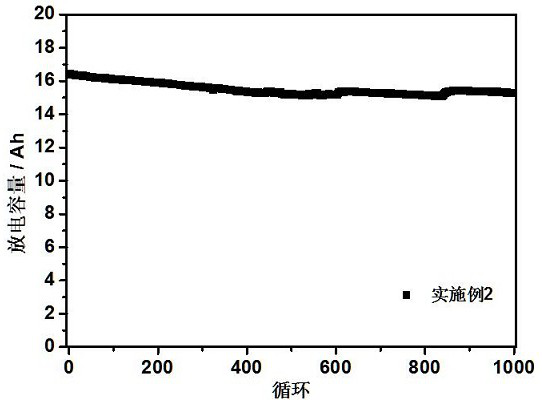

[0038] A high-wetting flame-retardant electrolyte formula, including the following raw materials: ethylene carbonate 25 g, diethyl carbonate 20 g, methyl ethyl carbonate 50 g, F127 0.3 g, ethyl propionate 5 g, F127 0.3 g, Fluoroethylene carbonate 5 g, vinylene carbonate 2 g, acetamide 2 g, ethoxypentafluorocyclotriphosphazene 5 g, difluorooxalate lithium borate 1 g, bisfluorosulfonimide lithium 2 g, Lithium hexafluorophosphate 15 g.

Embodiment 3

[0040] A high-wetting flame-retardant electrolyte formula, including the following raw materials by weight: ethylene carbonate 30 g, diethyl carbonate 20 g, methyl ethyl carbonate 50 g, ethyl propionate 10 g, F127 0.3 g, fluoroethylene carbonate 10 g ester, 2 g vinylene carbonate, 5 g acetamide, 8 g ethoxypentafluorocyclotriphosphazene, 1 g lithium difluorooxalate borate, 2 g lithium bistrifluoromethanesulfonimide, lithium hexafluorophosphate 15 g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com