Gradient coating for boiler tail heating surface and preparation method thereof

A tail heating surface, gradient coating technology, applied in the direction of coating, chemical instruments and methods, metal material coating technology, etc., to achieve high hardness, reduce the risk of cracking and peeling, and improve the effect of coating strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

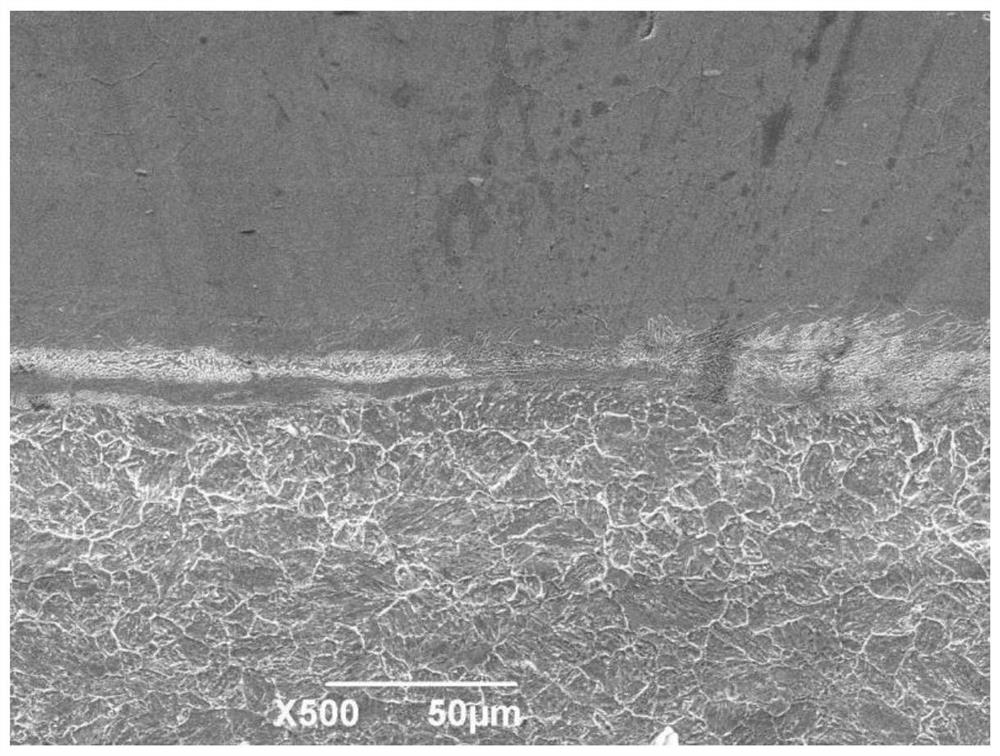

[0060] This embodiment provides a gradient coating for the heating surface of the boiler tail, and the gradient coating for the heating surface of the boiler tail includes a first coating, a second coating and a third coating; the first coating The layer, the second coating and the third coating are sequentially arranged from the heated surface close to the boiler tail and away from the heated surface of the boiler tail;

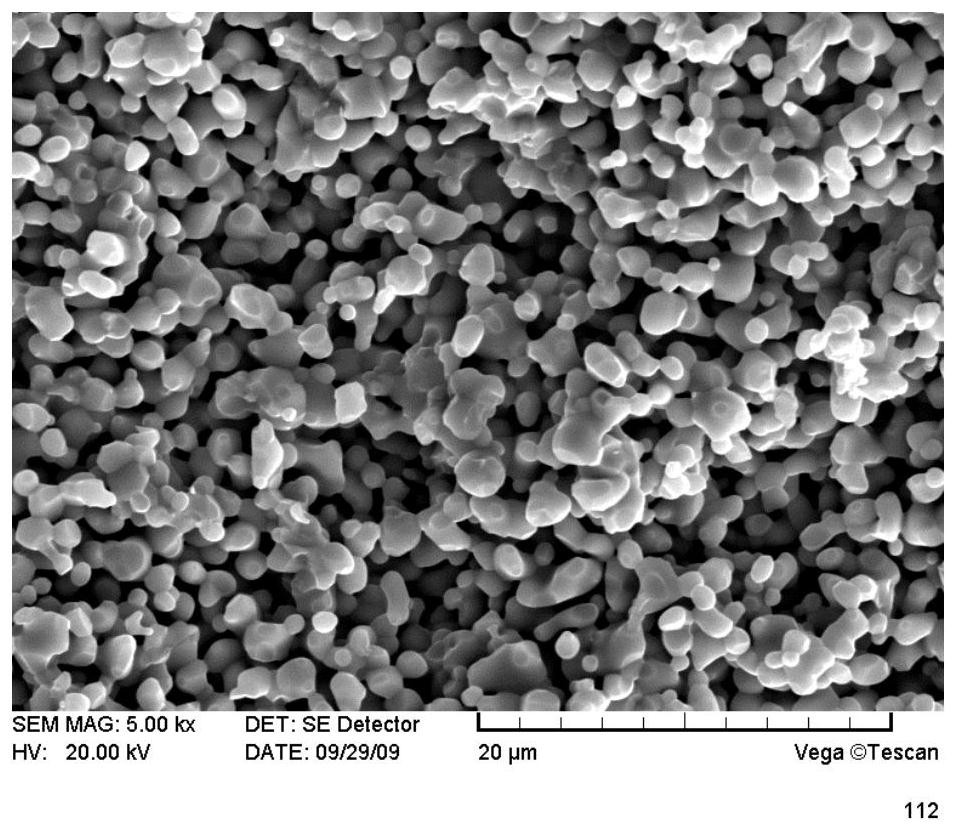

[0061] The raw materials of each coating include niobium carbide powder, modified graphene powder and zirconium-nickel-based amorphous alloy powder;

[0062] In the first coating layer, the mass percentage of niobium carbide powder is 5%, the mass percentage of modified graphene powder is 5%, and the mass percentage of zirconium-nickel-based amorphous alloy powder is 90%. ;

[0063]In the second coating layer, the mass percentage of niobium carbide powder is 9%, the mass percentage of modified graphene powder is 9%, and the mass percentage of zirconium-nick...

Embodiment 2

[0088] This embodiment provides a gradient coating for the heating surface of the boiler tail, and the gradient coating for the heating surface of the boiler tail includes a first coating, a second coating and a third coating; the first coating The layer, the second coating and the third coating are sequentially arranged from the heated surface close to the boiler tail and away from the heated surface of the boiler tail;

[0089] The raw materials of each coating include niobium carbide powder, modified graphene powder and zirconium-nickel-based amorphous alloy powder;

[0090] In the first coating layer, the mass percentage of niobium carbide powder is 6%, the mass percentage of modified graphene powder is 6%, and the mass percentage of zirconium-nickel-based amorphous alloy powder is 88% ;

[0091] In the second coating layer, the mass percentage of niobium carbide powder is 10%, the mass percentage of modified graphene powder is 10%, and the mass percentage of zirconium-ni...

Embodiment 3

[0114] This embodiment provides a gradient coating for the heating surface of the boiler tail, and the gradient coating for the heating surface of the boiler tail includes a first coating, a second coating and a third coating; the first coating The layer, the second coating and the third coating are sequentially arranged from the heated surface close to the boiler tail and away from the heated surface of the boiler tail;

[0115] The raw materials of each coating include niobium carbide powder, modified graphene powder and zirconium-nickel-based amorphous alloy powder;

[0116] In the first coating layer, the mass percentage of niobium carbide powder is 7%, the mass percentage of modified graphene powder is 7%, and the mass percentage of zirconium-nickel-based amorphous alloy powder is 86%. ;

[0117] In the second coating layer, the mass percentage of niobium carbide powder is 11%, the mass percentage of modified graphene powder is 11%, and the mass percentage of zirconium-n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com