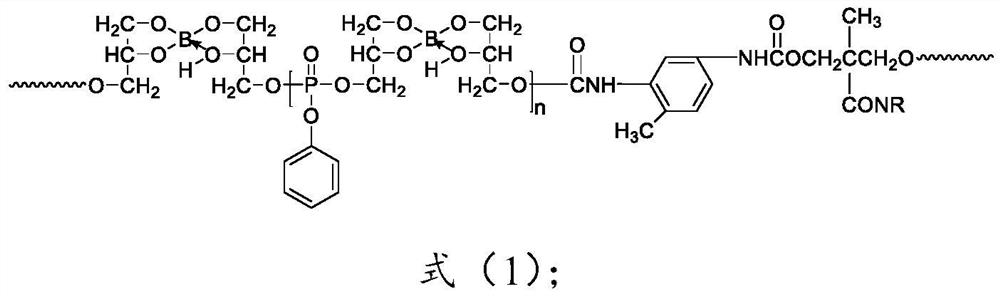

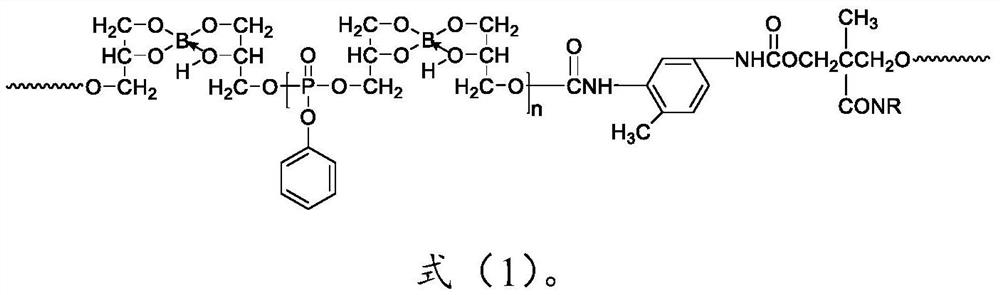

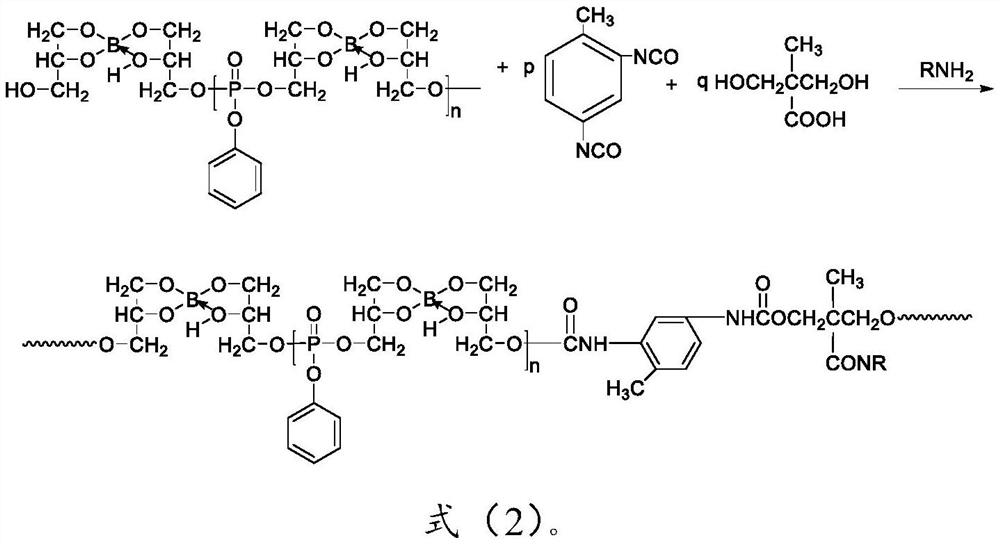

Phosphorus-boron heterochain prepolymer block polyurethane fabric flame-retardant water-based sizing agent and preparation method and application thereof

A prepolymer and polyurethane technology, applied in flame-retardant fibers, textiles and papermaking, fiber processing, etc., can solve the problems of easy powder loss, poor compatibility, and high dosage, and achieve the effect of smooth and wear-resistant hand feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0056] 1. The preparation of phosphobora chain prepolymer block polyurethane aqueous copolymer comprises the following steps:

[0057] (1) In a four-neck flask equipped with mechanical stirring, nitrogen protection, condensing reflux, water bath heating and temperature control devices, add 50ml xylene, 75g PDCP-DGB, and dibutyltin dilaurate accounting for 3‰ of TDI mass.

[0058] (2) Turn on stirring and nitrogen, and heat the reaction system in step (1) to 60±1°C in a water bath. After the heat preservation system is uniform, add 17.0g TDI and 8.0g DMPA dropwise, keep the system temperature at 75±1°C, and keep warm for 2h , separation and recovery of the upper xylene.

[0059] (3) Cool down the reaction system after separation and removal of xylene to 45±1°C, then add monoethanolamine and 50ml of water, continue stirring for 1 hour, adjust the pH=9.0, and then adjust the product viscosity to 1500Cp (25°C) with water , to obtain the diluent of phosphorus bora chain prepolymer...

no. 2 example

[0064] 1. The preparation of phosphobora chain prepolymer block polyurethane aqueous copolymer comprises the following steps:

[0065] (1) In a four-necked flask equipped with mechanical stirring, nitrogen protection, condensing reflux, water bath heating and temperature control devices, add 50ml of xylene, 77g of PDCP-DGB, and dibutyltin dilaurate accounting for 5‰ of TDI mass.

[0066] (2) Turn on stirring and blow nitrogen, heat the reaction system of step (1) in a water bath to 65±1°C, after the heat preservation system is uniform, add 16.0g TDI and 7.0g DMPA dropwise, keep the system temperature at 75±1°C, and keep warm for 1.5 h, separating and recovering the upper layer of xylene.

[0067] (3) Cool down the reaction system after separation and removal of xylene to 50±1°C, then add monoethanolamine and 50ml of water, continue stirring for 1 hour, adjust the pH=8.0, and then adjust the product viscosity to 1800Cp (25°C) with water , to obtain the diluent of phosphorus bo...

no. 3 example

[0072] 1. The preparation of phosphobora chain prepolymer block polyurethane aqueous copolymer comprises the following steps:

[0073] (1) In a four-neck flask equipped with mechanical stirring, nitrogen protection, condensing reflux, water bath heating and temperature control devices, add 50ml of xylene, 76.0g of PDCP-DGB, and dibutyltin dilaurate accounting for 4‰ of TDI mass.

[0074] (2) Turn on stirring and nitrogen gas, and heat the reaction system in step (1) to 60±1°C in a water bath. After the heat preservation system is uniform, add 16.5g TDI and 7.5g DMPA dropwise, keep the system temperature at 70±1°C, and keep warm for 2.5 h, separating and recovering the upper layer of xylene.

[0075] (3) Cool down the reaction system after separation and removal of xylene to 45±1°C, then add monoethylamine and 50ml of water, continue stirring for 1h, adjust the pH=7.5, and then adjust the product viscosity to 2000Cp (25°C) with water ), to obtain the diluent of phosphorus bora...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com