A non-aqueous glycol ether based heat exchange fluid medium

A technology of heat exchange fluid and glycol ether, which is applied in the direction of heat exchange materials, chemical instruments and methods, etc., can solve the problem that the protection performance of the working medium cannot meet the long-term work requirements, the maintenance is not very convenient, and the electronic system burns out, etc. problems, to achieve the effect of eliminating pitting corrosion of the lining, good resistance to storage and sterilization, and good effect of blocking electrical conduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

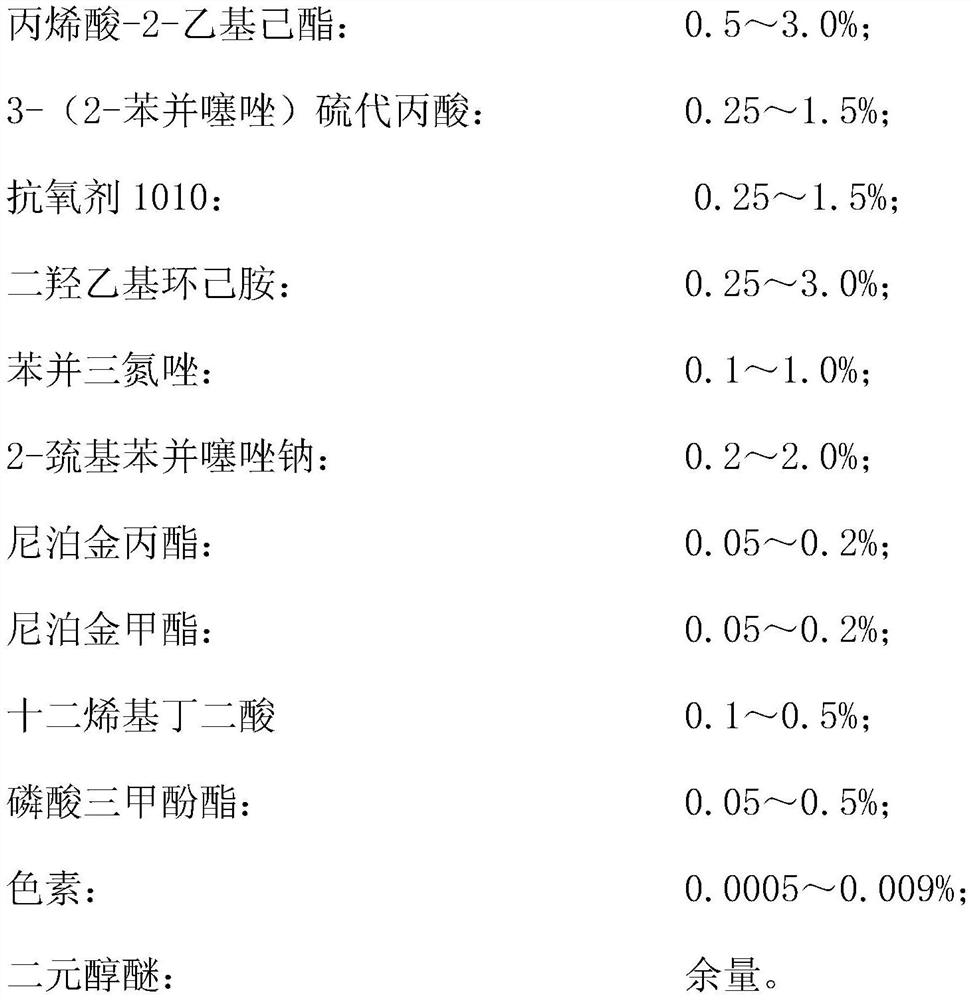

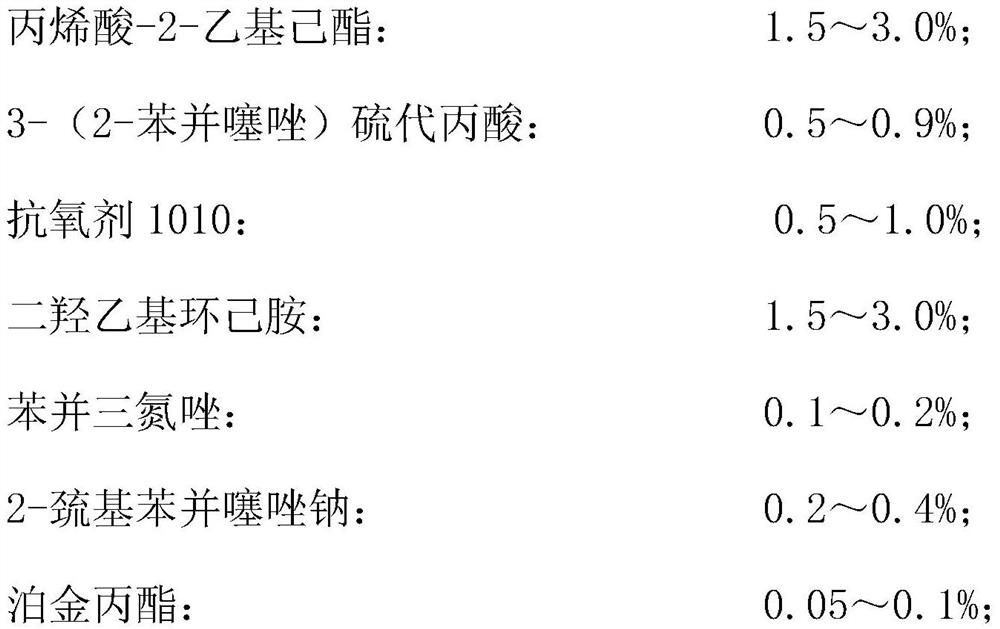

Method used

Image

Examples

Embodiment 1

[0026] Prepare 1000kg of a non-aqueous heat exchange fluid medium used in areas where the lowest temperature is below -60°C:

[0027] Put 600kg of propylene glycol methyl ether into the reaction kettle, keep the temperature in the kettle not exceeding 60°C, then add 2-ethylhexyl acrylate: 20kg, 3-(2-benzothiazole)thiopropionic acid: 7kg, antioxidant Agent 1010: 7kg, benzotriazole: 1.5kg, sodium 2-mercaptobenzothiazole: 3kg, propylparaben: 0.6kg, methylparaben: 0.6kg, dodecenylsuccinic acid: 1kg, tricresyl phosphate: 1.8kg, the time interval for adding the above additives is 10 minutes, after the addition is completed, stir for half an hour and then add dihydroxyethylcyclohexylamine: 27kg, Orisol 2B red: 0.05kg, and then Add the remaining amount of 1,2-propanediol and continue to stir for 6 hours to finally form a pink transparent solution. After passing the inspection, filter through a 0.5-1 μm filter before packaging.

[0028] The general technical indicators and the specifi...

Embodiment 2

[0033] Prepare 1000kg of heat exchange fluid medium for use in a low temperature environment below -65°C:

[0034] Put 500kg of propylene glycol methyl ether and 200kg of diethylene glycol methyl ether mixture into the reaction kettle, keep the temperature in the kettle not exceeding 60°C, then add 2-ethylhexyl acrylate: 25kg, 3-(2-benzothiazole ) Thiopropionic acid: 8kg, antioxidant 1010: 8kg, benzotriazole: 2kg, sodium 2-mercaptobenzothiazole: 4kg, propylparaben: 0.5kg, methylparaben: 0.5kg , dodecenylsuccinic acid: 1.2kg, tricresyl phosphate: 2kg, the time interval for adding the above-mentioned additives is 10 minutes, after adding, stir for half an hour and then add dihydroxyethylcyclohexylamine: 28kg, Austrian Lisu 2B Red: 0.05kg, add the remaining 1,2-propanediol and continue to stir for 6 hours to form a pink transparent solution. After passing the inspection, filter it through a 0.5-1μm filter and pack it .

[0035] The specific parameters of the glassware corrosion...

Embodiment 3

[0040] Prepare 1000kg of wind power heat exchange fluid medium for use in low temperature environments below -60°C:

[0041] Put 750kg of propylene glycol ethyl ether into the reaction kettle, keep the temperature in the kettle not exceeding 60°C, then add 2-ethylhexyl acrylate: 16kg, 3-(2-benzothiazole)thiopropionic acid: 9kg, antioxidant Agent 1010: 7.5kg, benzotriazole: 10kg, sodium 2-mercaptobenzothiazole: 20kg, propylparaben: 2kg, methylparaben: 2kg, dodecenylsuccinic acid: 5kg, Tricresyl phosphate: 5kg, the time interval for adding the above additives is 10 minutes, after the addition is completed, stir for half an hour and then add dihydroxyethylcyclohexylamine: 30kg, Orisol 2B red: 0.09kg, add the remaining After diethylene glycol continued to stir for 6 hours, a pink transparent solution was finally formed. After passing the inspection, it was filtered through a 0.5-1 μm filter before packaging.

[0042] The specific parameters of the glassware corrosion test are as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com