Processing method of black ginseng

A processing method and technology of black ginseng, which can be applied to medical formulas, medical preparations containing active ingredients, anti-toxins, etc., can solve the problems of poor economy, short natural aging time, single type of rare saponins, etc., and achieve no harmful substance residues , Inhibit the growth of bacteria and avoid the effect of carbonization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The present embodiment provides a kind of processing method of black ginseng, it comprises the following steps:

[0026] (1) Fresh ginseng pre-treatment: Take 4-year-old fresh ginseng, wash it clean, and then dry it at 45°C to control the water content to 15%, then store it in an environment of 1-5°C 6 months.

[0027] (2) Take the preserved fresh ginseng, clean it, and remove the water on the outer surface; then dry it at 45° C. until the water content is 80%.

[0028] (3) Then place it in a sealed tank, feed nitrogen to maintain an oxygen-free environment in the tank and control the reaction pressure in the tank to 20MPa, start heating, control the temperature to 60°C, and react at this temperature for 24h; then Raise the temperature to 85°C, and react at this temperature for 360-480 hours (wherein, every 120 hours, the sealed tank is opened for deflation for 3 minutes), and a tan product is obtained, which is black ginseng.

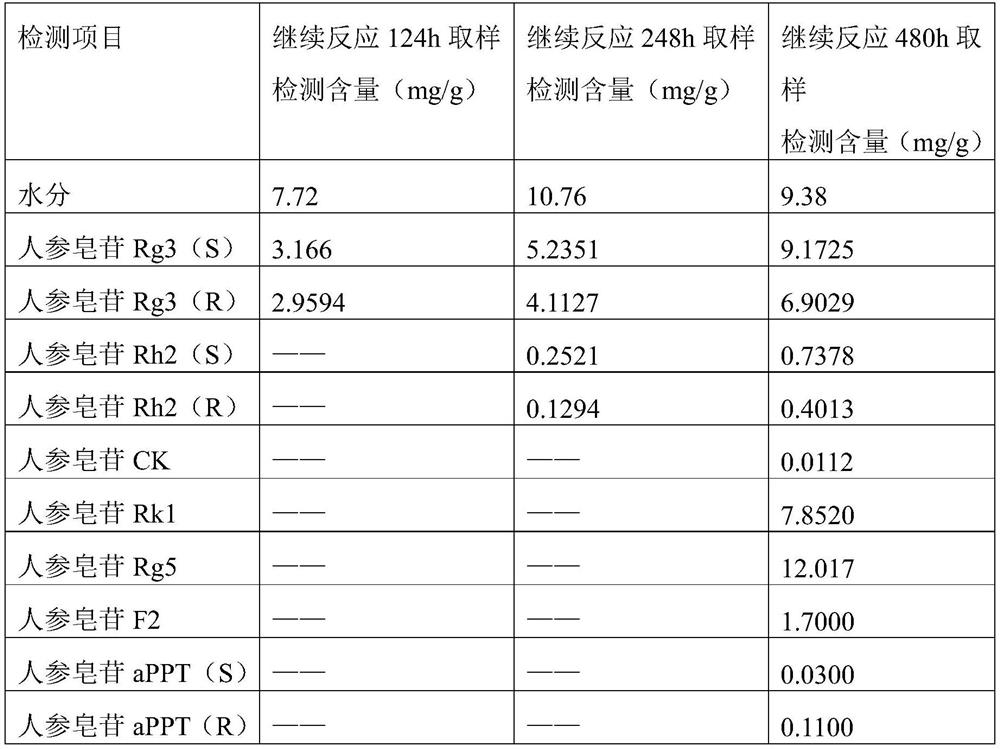

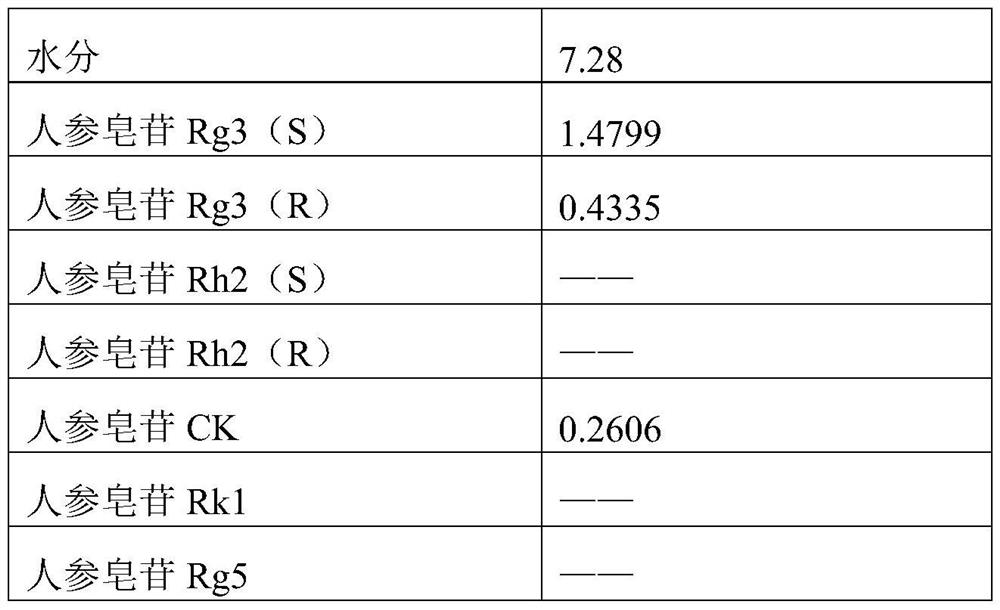

[0029] In the sealed tank, samples were...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com