Electromagnetic shielding adhesive tape and preparation method of hexagonal-boron-nitride-nanosheet-modified double-sided conductive adhesive tape layer thereof

A technology of hexagonal boron nitride and conductive tape, applied in the direction of conductive adhesives, film/sheet adhesives, adhesives, etc., can solve the problem of increasing product weight, inevitable gaps and openings in shielding frames, and affecting shielding covers Conductivity and integrity and other issues, to achieve the effect of improving flexibility and conductivity, improving adhesion and reducing fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

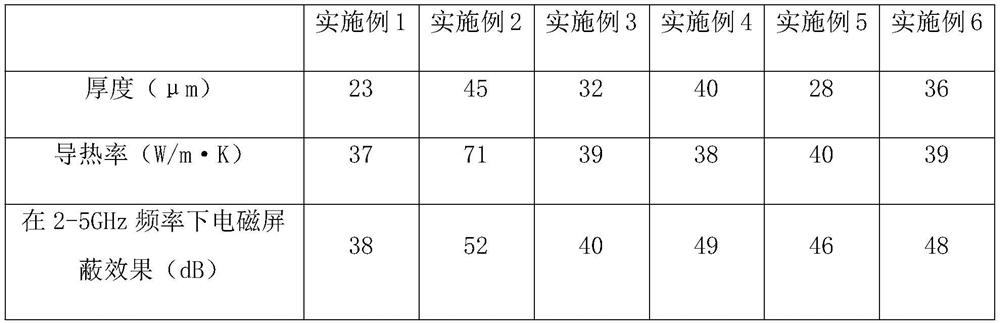

Examples

Embodiment 1

[0026] (1) Add the hexagonal boron nitride powder into the tetrahydrofuran solution, stir, ultrasonically disperse at 800W for 1-2h, centrifuge at 10000r / min for 15-30min, take the supernatant, dry and grind to obtain the size Hexagonal boron nitride nanosheet material with a thickness of 0.4-0.7 μm and a thickness of 0.9-2 nm.

[0027] (2) Add dopamine hydrochloride into the buffer solution, stir evenly, according to the mass ratio of dopamine hydrochloride and hexagonal boron nitride nanosheet material is 1:2.5, add hexagonal boron nitride nanosheet material, at 35 ℃ Heating and pre-reacting for 2 hours to obtain a polydopamine-modified hexagonal boron nitride nanosheet solution.

[0028] (3) According to the mass ratio of butyl acrylate, methyl methacrylate, acrylic acid, hydroxyethyl acrylate and polydopamine-modified hexagonal boron nitride nanosheets as 90:15:3:2:8, butyl acrylate , methyl methacrylate, acrylic acid and hydroxyethyl acrylate were added to a weak alkalin...

Embodiment 2

[0032] (1) Add the hexagonal boron nitride powder into the tetrahydrofuran solution, stir, ultrasonically disperse at 1000W for 2h, centrifuge at 11000r / min for 30min, take the supernatant, dry and grind to obtain a size of 0.4-0.7 μm, hexagonal boron nitride nanosheet material with a thickness of 0.9-2nm.

[0033] (2) Add dopamine hydrochloride into the buffer solution, stir evenly, according to the mass ratio of dopamine hydrochloride and hexagonal boron nitride nanosheet material is 1:3, add hexagonal boron nitride nanosheet material, at 40 ℃ Pre-react by heating for 4 hours to obtain a polydopamine-modified hexagonal boron nitride nanosheet solution.

[0034] (3) According to the mass ratio of butyl acrylate, methyl methacrylate, acrylic acid, hydroxyethyl acrylate and polydopamine-modified hexagonal boron nitride nanosheets as 100:20:5:4:10, butyl acrylate , methyl methacrylate, acrylic acid, and hydroxyethyl acrylate were added to a weak alkaline solvent, heated and emuls...

Embodiment 3

[0038] (1) Add the hexagonal boron nitride powder into the tetrahydrofuran solution, stir, ultrasonically disperse at 900W for 1.5h, centrifuge at 10500r / min for 20min, take the supernatant, dry it, and grind it to obtain a solution with a size of 0.4- 0.7μm, hexagonal boron nitride nanosheet material with a thickness of 0.9-2nm.

[0039] (2) Add dopamine hydrochloride into the buffer, stir evenly, according to the mass ratio of dopamine hydrochloride and hexagonal boron nitride nanosheet material is 1:2.8, add hexagonal boron nitride nanosheet material, at 38 ℃ Heating and pre-reacting for 3 hours to obtain a polydopamine-modified hexagonal boron nitride nanosheet solution.

[0040] (3) According to the mass ratio of butyl acrylate, methyl methacrylate, acrylic acid, hydroxyethyl acrylate and polydopamine-modified hexagonal boron nitride nanosheets as 95:18:4:3:9, butyl acrylate , methyl methacrylate, acrylic acid, and hydroxyethyl acrylate were added to a weak alkaline solv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com