Hygroscopic heating yarn and preparation method and application thereof

A technology of moisture absorption and heating, yarn, applied in wet spinning, spinning solution preparation, yarn, etc., can solve the problems of high maintenance requirements, non-alkali and acid resistance, easy to wrinkle, etc., and achieve good application and high hygroscopicity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

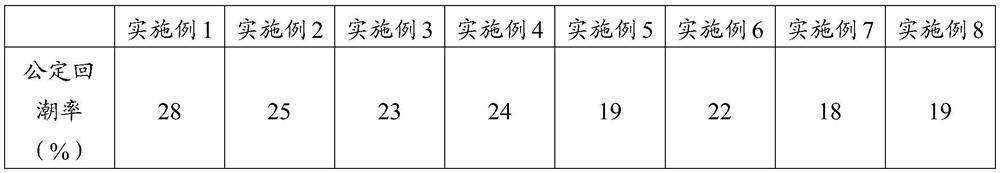

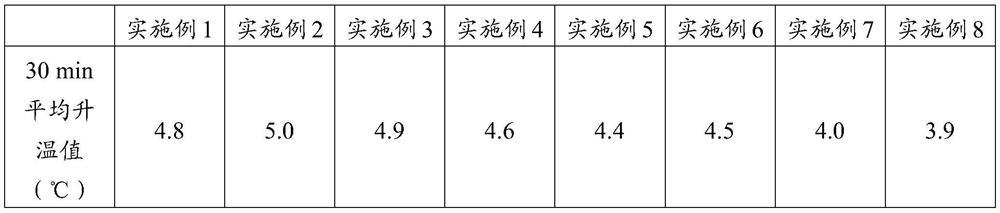

Examples

Embodiment 1

[0023]5g of polyacrylonitrile was added to 100g of strong base solvent to carry out the hydrolysis reaction. The strong base solvent was made up of 10mL ethanol, 10g sodium hydroxide and deionized water, and reacted at 100°C for 3h; the hydrolysate was adjusted to pH 5.5; then add the crosslinking agent triallyl cyanurate to carry out the crosslinking reaction at 125°C for 2h, and the mass of the crosslinking agent is 0.03% of the mass of the polyacrylonitrile. The cross-linked product was added to a zinc chloride aqueous solution with a concentration of 20wt.% and then subjected to wet spinning. The spinning speed of the wet spinning was 15m / min, the draft ratio was 3.8, and the winding speed was 25m / min. , The drying temperature is 130 ℃; finally, the fiber obtained by wet spinning is mixed with wool fiber at a blending ratio of 20:80, and then through the processes of opening, carding, combing, drawing, roving and spinning to obtain moisture-absorbing heating yarn line.

Embodiment 2

[0025]Add 5g of polyacrylonitrile to 100g of a strong base solvent to carry out the hydrolysis reaction. The strong base solvent is made up of 12mL of ethanol, 15g of sodium hydroxide and deionized water, and reacted at 85°C for 4h; the hydrolysate is adjusted to The pH is 6.5; the crosslinking agent triallyl cyanurate is added to carry out the crosslinking reaction at 120° C. for 1.5 hours, and the mass of the crosslinking agent is 0.08% of the mass of the polyacrylonitrile. The crosslinked product was added to a 25wt.% aqueous sodium thiocyanate solution and then subjected to wet spinning. The spinning speed of the wet spinning was 15m / min, the draft ratio was 3.5, and the winding speed was 20m / min. min, the drying temperature is 140℃; finally, the fiber obtained by wet spinning is mixed with wool fiber at a blending ratio of 20:80, and then through the processes of opening, carding, combing, drawing, roving and spinning to obtain moisture and heat generation Yarn.

Embodiment 3

[0027]Add 5g of polyacrylonitrile to 100g of strong base solvent for hydrolysis reaction, the strong base solvent is made up of 15mL ethanol, 2.8g sodium hydroxide and deionized water, react at 80℃ for 5h; add nitric acid to the hydrolyzate to adjust To pH 7.0; then add the cross-linking agent polyethyleneimine to carry out the cross-linking reaction at 140° C. for 1 h, and the mass of the cross-linking agent is 0.10% to the mass of the polyacrylonitrile. The crosslinked product was added to a sodium thiocyanate aqueous solution with a concentration of 30wt.% and then subjected to wet spinning. The spinning speed of the wet spinning was 17m / min, the draft ratio was 2.5, and the winding speed was 30m / min. min, the drying temperature is 150℃; finally, the fiber obtained by wet spinning is mixed with cotton fiber at a blending ratio of 25:75, and then through the processes of opening, carding, combing, drawing, roving and spinning to obtain moisture and heat generation Yarn.

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com