A kind of strongly electron-withdrawing element doped rare earth orthosilicate scintillation material and its preparation method and application

An orthosilicate, electronic element technology, applied in the preparation/processing of rare earth metal compounds, luminescent materials, scintillation components, etc., can solve the problem of shortening the duration of the main amplitude component of the scintillation response, adding high content of doping ions, shortening the Issues such as emission duration, to achieve the effect of shortening the luminous decay time and rise time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

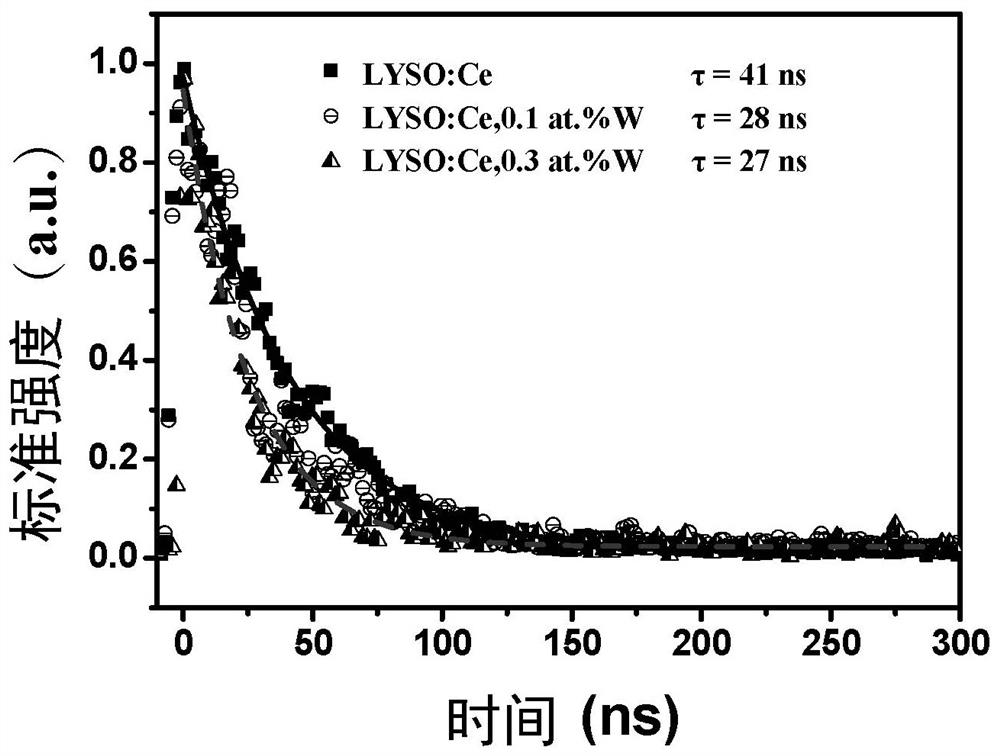

[0054] Embodiment 1 (growth W-doped single crystal)

[0055] Single crystals were grown by the pulling method. Molar ratio WO 3 :CeO 2 :SiO2 2 :Lu 2 o 3 :Y 2 o 3 =2y:0.002:1:0.899-y:0.1 Ingredients (y=0.001, 0.003, 0.005, 0.01), fully mixed, the mixture is pressed into a block under 2500MPa cold isostatic pressure, put into an iridium crucible, through induction Heating and fully melting, and slowly growing a single crystal with a preset size from the melt after inoculation of the seed crystal to obtain Lu 1.798-2y Y 0.2 Ce 0.002 W 2y SiO 5 single crystal.

Embodiment 2

[0056] Embodiment 2 (preparation of W-doped polycrystalline powder)

[0057] According to the ingredients in Example 1, mix thoroughly and evenly, put the powder mixture into a corundum crucible, put it in a muffle furnace, and calcinate at 1600 ° C for 10 hours to undergo a solid phase reaction to obtain Lu 1.798-2y Y0.2 Ce 0.002 W 2y SiO 5 polycrystalline powder.

Embodiment 3

[0058] Embodiment 3 (preparation of W-doped ceramics)

[0059] Non-transparent: mix the ingredients according to Example 1, mix well, press the mixture into a block under 30MPa cold isostatic pressure, put it into a corundum crucible, put it in a muffle furnace, and sinter at 1600 ° C for 10 hours to undergo a solid-state reaction to obtain Lu 1.798- 2y Y 0.2 Ce 0.002 W 2y SiO 5 or Lu 1.798-2y+2y / z Y 0.2 Ce 0.002 W 2y Si (1-2y / z) o 5 Opaque ceramic. Transparent: According to the ingredients in Example 1, fully mix evenly, press the mixture into a block under 5000MPa cold isostatic pressure, and undergo a solid-phase reaction in a vacuum hot-press furnace to remove air bubbles and voids as much as possible to obtain Lu 1.798-2y Y 0.2 Ce 0.002 W 2y SiO 5 Transparent ceramic.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com