Antistatic impregnating compound for glass fibers and preparation method thereof

A technology of glass fiber and antistatic agent, which is applied in the field of glass fiber antistatic sizing agent and its preparation, can solve the problems that cannot meet the needs of the production workshop, and achieve the reduction of hairiness, lower dynamic friction coefficient, and excellent antistatic effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

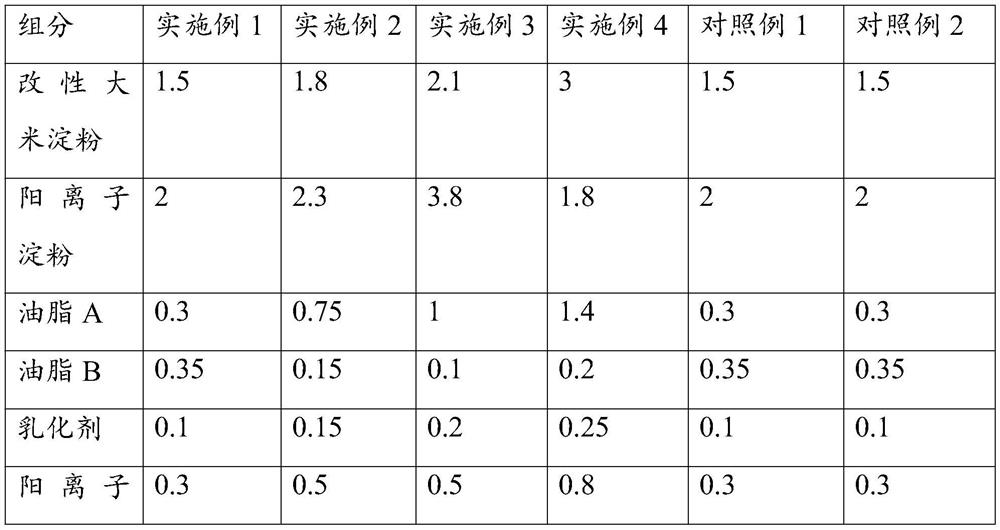

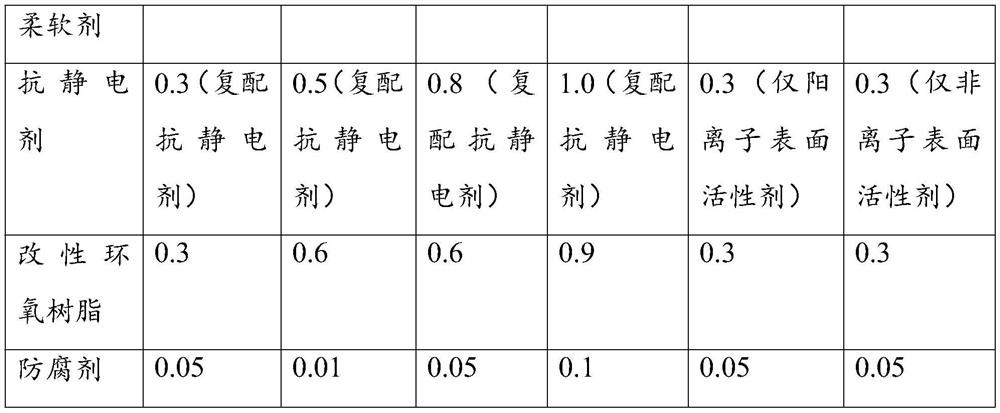

Examples

Embodiment 1

[0048] S1. After adding modified rice starch and cationic starch to 50% of the total amount of the preparation, start stirring, and simultaneously heat up to 85° C., and treat at a constant temperature for 30 minutes; wherein, the solubility of modified rice starch is 30%, and the solubility of cationic starch is 100% starch tertiary amino alkyl ether.

[0049] S2. Mix and stir the preheated grease A, grease B, emulsifier and cationic softener, and heat up to 60°C, then add 50% of the total amount of grease A, grease B, emulsifier and cationic softener Water at 65°C until the emulsification is complete to obtain an emulsion; among them, fat A is glyceride; fat B is C 12 and C 18 Fatty acid esters composed of C 30 The fatty acid ester mixture; the emulsifier is a compound emulsifier composed of polyoxyethylene polyoxypropylene ether and fatty acid polyoxyethylene amide with a mass ratio of 1:1; the cationic softener is C 12 The product obtained by the reaction of fatty acids...

Embodiment 2

[0053] S1. Add modified rice starch and cationic starch to water with 55% of the total amount prepared and start stirring. Simultaneously, the temperature is raised to 95° C. and treated at a constant temperature for 40 minutes. Among them, the solubility of modified rice starch is 20%, and the solubility of cationic starch is 100% quaternary ammonium starch ether.

[0054] S2. Mix and stir the preheated grease A, grease B, emulsifier and cationic softener, and heat up to 65°C, then add 55% of the total amount of grease A, grease B, emulsifier and cationic softener Water at 60°C until the emulsification is complete to obtain an emulsion, wherein fat A is hydrogenated corn oil; fat B is C 18 Fatty acid ester; the emulsifier is a composite emulsifier composed of sorbitan oleate and polyoxyethylene sorbitan oleate in a mass ratio of 1:1; the cationic softener is C 18 The product obtained by the reaction of fatty acids with diethylenetriamine.

[0055] S3. Add water at 30°C to t...

Embodiment 3

[0058] S1, add modified rice starch and cationic starch to the water of 65% of the total amount of preparation, start stirring, and simultaneously heat up to 100 ° C, and treat at a constant temperature for 50 minutes, wherein the solubility of modified rice starch is 30%, and the solubility of cationic starch is 100% quaternary ammonium starch ether.

[0059] S2. Mix and stir the preheated grease A, grease B, emulsifier and cationic softener, and heat up to 70°C, then add 60% of the total amount of grease A, grease B, emulsifier and cationic softener Water at 70°C until the emulsification is complete to obtain an emulsion, wherein fat A is hydrogenated palm oil; fat B is C 12 Fatty acid esters composed of C 24 fatty acid ester; emulsifier is a compound emulsifier composed of sorbitan stearate and polyoxyethylene ether sorbitan stearate with a mass ratio of 1:1; the cationic softener is C 12 The product obtained by the reaction of fatty acids with tetraethylenepentamine.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com