CNF-reinforced steel slag-based geopolymer cementing material, molded body and preparation and application thereof

A technology of polymer glue and molded body, applied in cement production and other directions, can solve the problems of low environmental protection advantages of cementitious materials, low proportion of steel slag, energy consumption, etc., and achieve good industrialization prospects, good mechanical properties, and good comprehensiveness. The effect of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] In the preparation method provided by the present invention, those skilled in the art can choose a suitable method to prepare the molded body from each raw material of the CNF-reinforced steel slag-based geopolymer cementitious material. For example, in the preparation process, when CNF and steel slag are mixed, the method of test grinding and ball milling can be used to grind small-sized steel slag into steel slag powder, and CNF is evenly dispersed in steel slag powder to form uniform CNF and steel slag powder. Steel slag powder mixture; as another example, the curing temperature condition can be room temperature, preferably, the curing temperature condition can be 20-30°C.

[0036] As part of the core technical concept of this technical solution, by ball milling CNF and 2-5mm steel slag in a test mill in a specific proportion, the provided CNF and steel slag powder mixture, and a certain proportion of sodium silicate, NaOH and water prepared alkali After the activato...

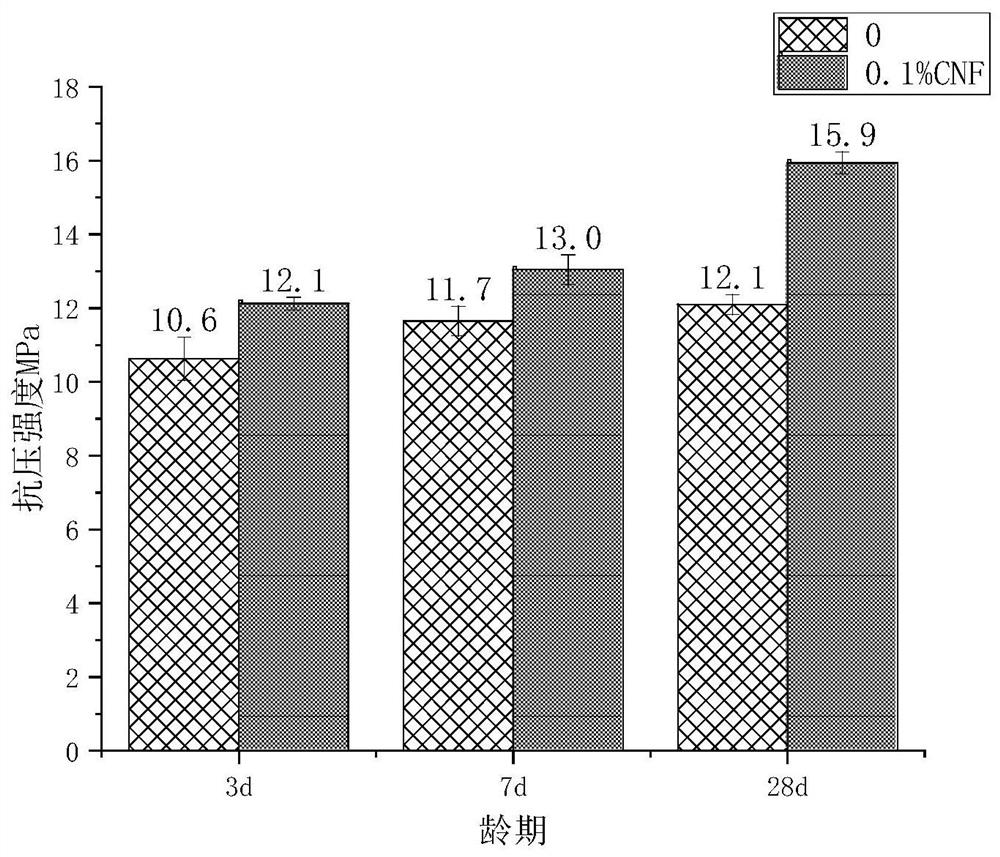

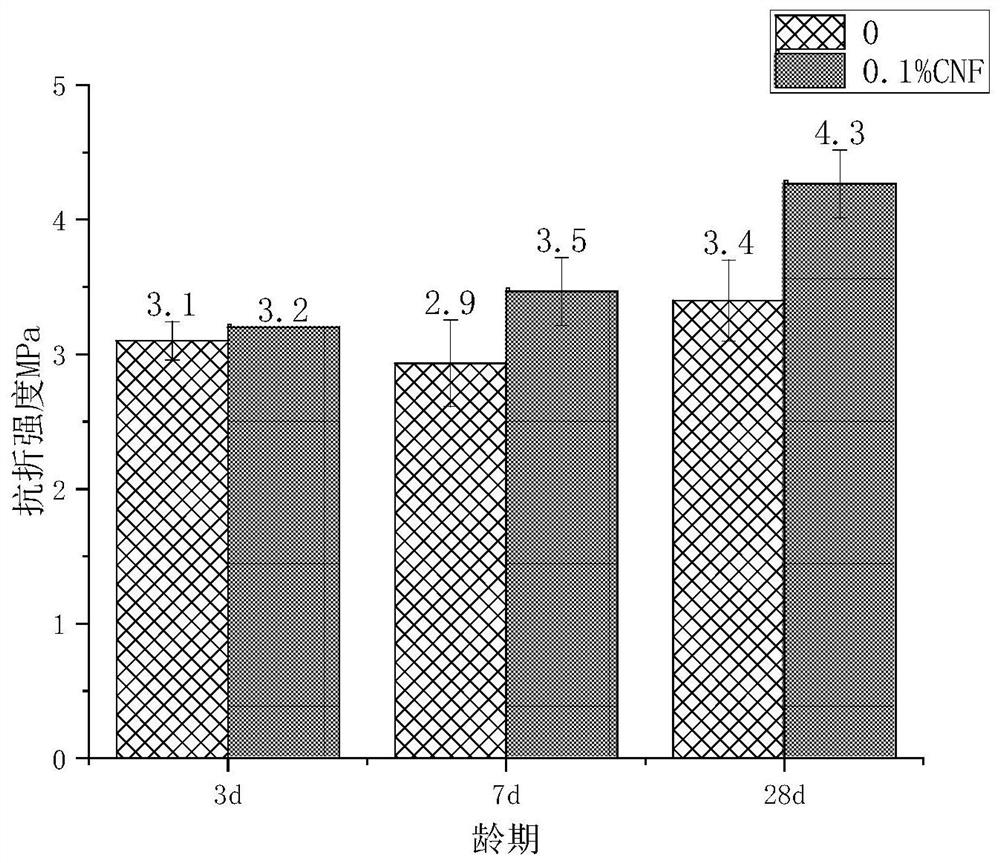

Embodiment 1

[0050] The small particle size (2-5mm) steel slag produced by Taizhen Mineral Products Processing Plant, Lingshou County, Shijiazhuang City, Hebei Province is selected, and its main chemical composition is 36.54% CaO, 24.56% Fe 2 o 3 , 15.64% SiO 2 , 7.39% MgO, 5.43% Al 2 o 3 , 4.54% MnO, 2.62% P 2 o 5 , 1.75% TiO 2 , 1.53% other components, loss on ignition is 3.63% (both mass percentage); analytical pure NaOH of Shanghai Aladdin Biochemical Technology Co., Ltd.; industrial water glass of Shandong Youso Chemical Factory, modulus 3.3, its main chemical composition 8.11% Na 2 O, 5.89% SiO 2 , 66%H 2 O; XFM60CNF (diameter 50-200nm, length 1-15μm, purity ≥ 95%) of Nanjing Xianfeng Nano Material Technology Co., Ltd., the dosage is 0.1% of the steel slag quality; distilled water; choose SM-500 test mill suggested by Wuxi, Jiangsu, The rotating speed is 48r / min.

[0051] Preparation method comprises the following steps in the present embodiment:

[0052] (1) Add 3g of CNF...

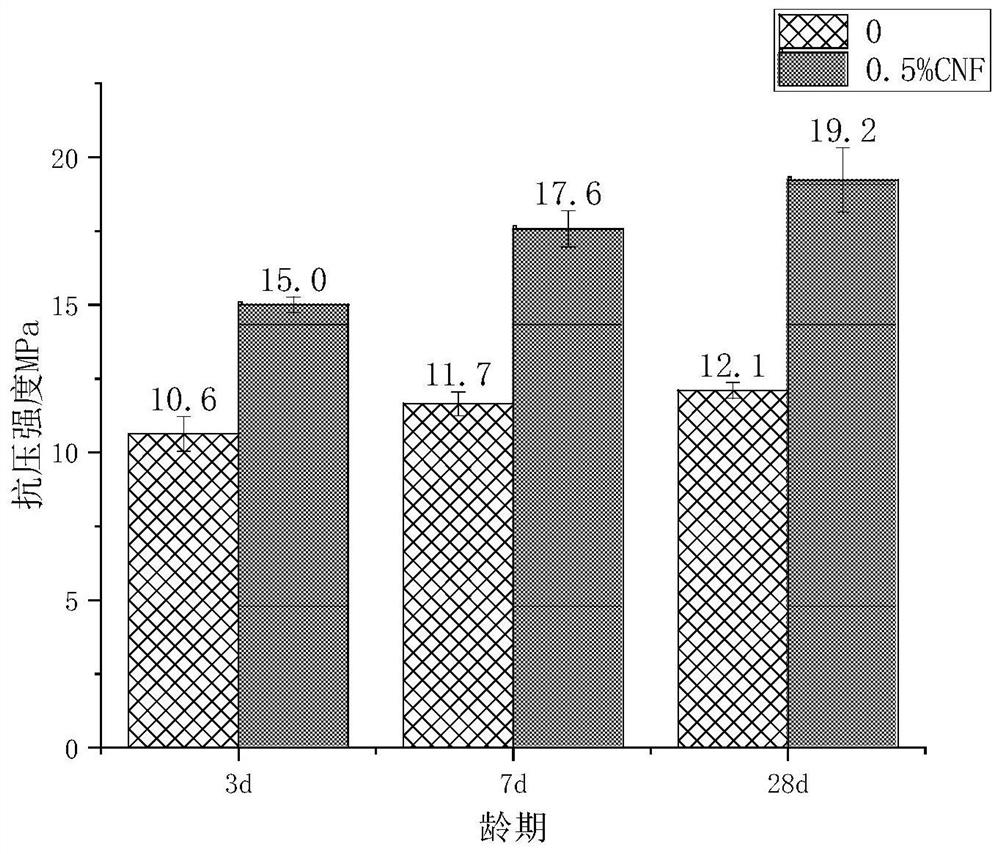

Embodiment 2

[0059] This embodiment selects the small particle size (2~5mm) steel slag produced by Taizhen Mineral Products Processing Plant, Lingshou County, Shijiazhuang City, Hebei Province, and its main chemical composition is 36.54% CaO, 24.56% Fe 2 o 3 , 15.64% SiO 2 , 7.39% MgO, 5.43% Al 2 o 3 , 4.54% MnO, 2.62% P 2 o 5 , 1.75% TiO 2 , 1.53% other components, loss on ignition is 3.63% (both mass percentage); analytical pure NaOH of Shanghai Aladdin Biochemical Technology Co., Ltd.; industrial water glass of Shandong Youso Chemical Factory, modulus 3.3, its main chemical composition 8.11% Na 2 O, 5.89% SiO 2 , 66%H 2 O; XFM60CNF (diameter 50-200nm, length 1-15μm, purity ≥ 95%) of Nanjing Xianfeng Nano Material Technology Co., Ltd., the dosage is 0.5% of the steel slag quality; distilled water; choose SM-500 test mill suggested by Wuxi, Jiangsu, The rotating speed is 48r / min.

[0060] The CNF reinforced steel slag-based geopolymer in this example is prepared by the following...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Flexural strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap