Dark red fluorescent powder for plant growth lamp and preparation method thereof

A technology of plant growth lamps and phosphors, applied in botany equipment and methods, chemical instruments and methods, and optical elements used to change the spectral characteristics of emitted light, etc., can solve the problem of difficult control of crystal distribution, type and depth, etc. problem, achieve the effect of low cost, simple preparation process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

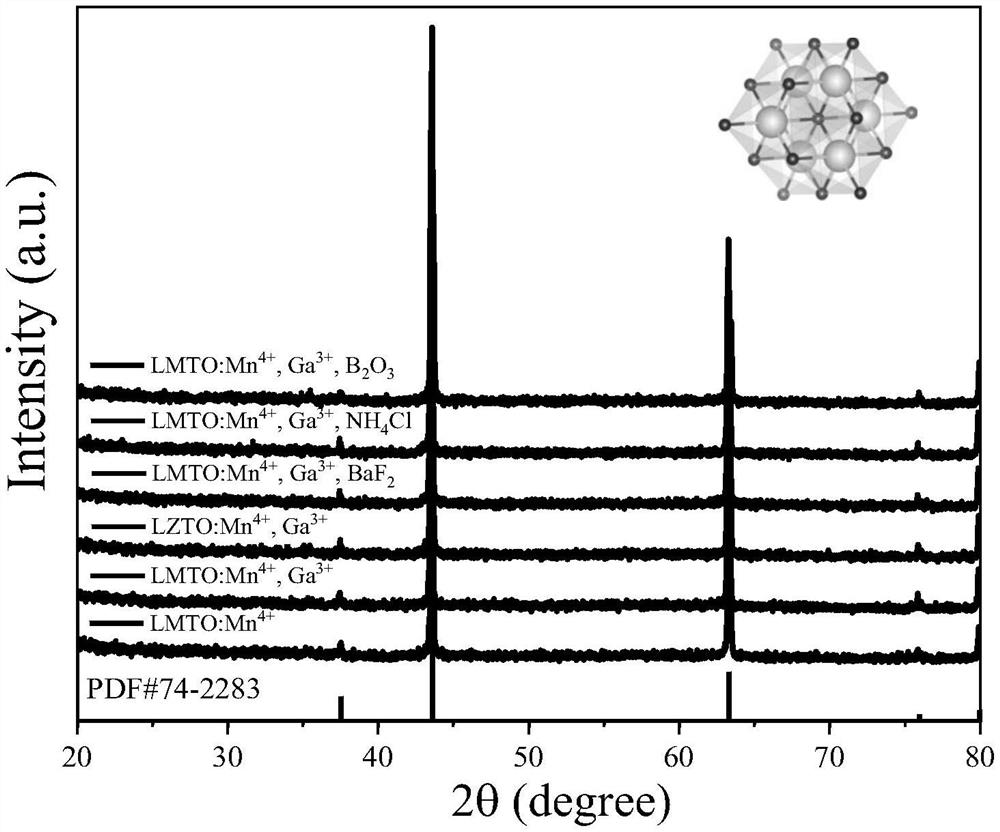

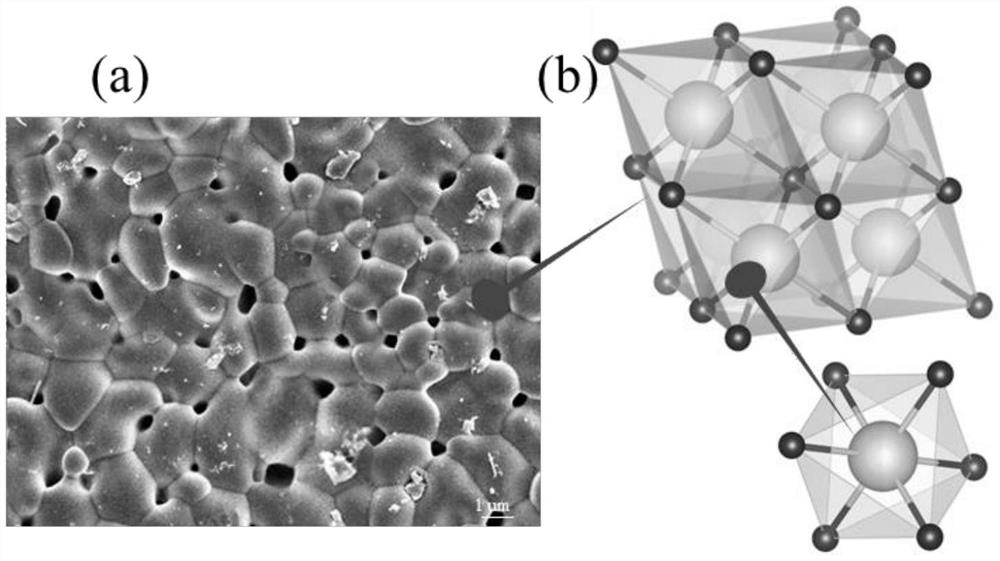

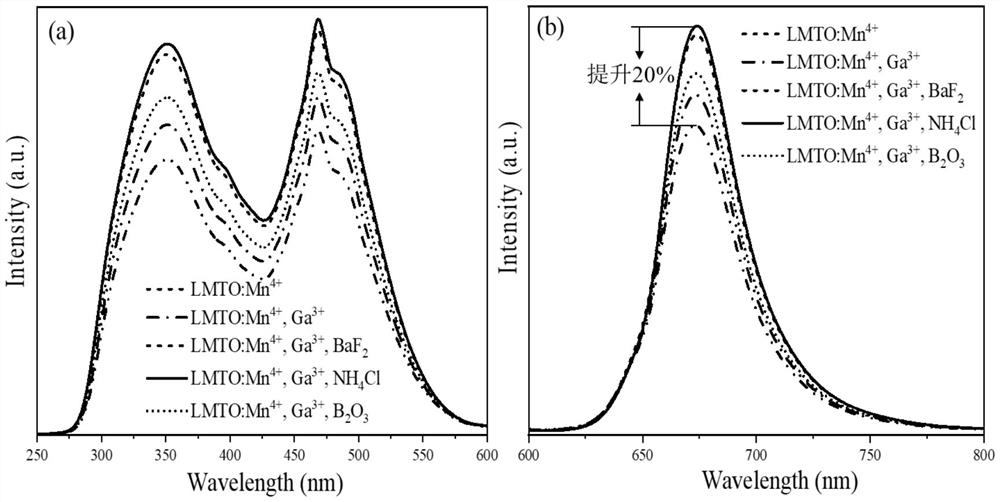

[0029] Example 1: Li 2 MTi(1- x - y )O 4 : x mn 4+ , y Ga 3+

[0030] According to Li 2 MTi(1- x - y )O 4 : x mn 4+ , y Ga 3+ ( x =0, 0.2%, 0.4%, 0.6%, 0.8%, 1.0%; y =0,0.1, 0.2, 0.3, 0.4, 0.5) stoichiometric ratio, weigh Li 2 CO 3 (AR), TiO 2 (AR), MgO (AR), ZnO(AR), MnO 2 (AR), Ga 2 o 3 (AR) were mixed, and another 5 mol% Li was weighed 2 CO 3 Compensation for Li ions evaporated at high temperature. The obtained mixed product was placed in an agate mortar, 5 mg of absolute ethanol was added, and then ground for 20-50 min until the mixture was uniform. Then the obtained sample powder was placed in a quartz crucible, heated at 6°C / min to 600-800°C for preheating for 6 h, then cooled to room temperature naturally, grinded again to improve uniformity, and then continued to be heated to 1100°C in an air environment. ~1300 °C for 2 h, then cooled to room temperature naturally. Finally, the obtained solid sample was ground again in an agate mortar to obta...

Embodiment 2

[0032] Example 2: Li 2 MgTiO 4 : Mn 4+ , Ga 3+ , BaF 2

[0033] According to Li 2 MgTi(1- x - y )O 4 : x mn 4+ , y Ga 3+ ( x =0, 0.2%, 0.4%, 0.6%, 0.8%, 1.0%; y =0,0.1, 0.2, 0.3, 0.4, 0.5) stoichiometric ratio, weigh Li 2 CO 3 (AR), TiO 2 (AR), MgO (AR), ZnO(AR), MnO 2 (AR), Ga 2 o 3 (AR) mixed, and weighed 5mol% Li 2 CO 3 Compensation for Li ions evaporated at high temperature. Then weigh an appropriate amount of 1.0~3.0wt% flux BaF 2 . The obtained mixed product was placed in an agate mortar, 5 mg of absolute ethanol was added, and then ground for 30 min until the mixture was homogeneous. Then the obtained sample powder was placed in a quartz crucible, heated to 600 °C at 6 °C / min for preheating for 6 h, then cooled to room temperature naturally, and the uniformity was improved after grinding again, and then continued to be heated to a constant temperature of 1300 °C in an air environment 2 h, and then cooled to room temperature naturally. Finally, ...

Embodiment 3

[0034] Example 3: Li 2 MgTiO 4 : Mn 4+ , Ga 3+ , NH 4 Cl

[0035] According to Li 2 MgTi(1- x - y )O 4 : x mn 4+ , y Ga 3+ ( x =0, 0.2%, 0.4%, 0.6%, 0.8%, 1.0%; y =0,0.1, 0.2, 0.3, 0.4, 0.5) stoichiometric ratio, weigh Li 2 CO 3 (AR), TiO 2 (AR), MgO (AR), ZnO(AR), MnO 2 (AR), Ga 2 o 3 (AR) mixed, and weighed 5mol% Li 2 CO 3 Compensation for Li ions evaporated at high temperature. Then weigh an appropriate amount of 1.0~3.0wt% flux NH 4 Cl. The obtained mixed product was placed in an agate mortar, 5 mg of absolute ethanol was added, and then ground for 30 min until the mixture was homogeneous. Then the obtained sample powder was placed in a quartz crucible, heated to 600 °C at 6 °C / min for preheating for 6 h, then cooled to room temperature naturally, and the uniformity was improved after grinding again, and then continued to be heated to a constant temperature of 1300 °C in an air environment 2 h, and then cooled to room temperature naturally. Finall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com