Preparation of high-wear-resistance anti-friction aromatic nitrogenous borate lubricating oil additive

A technology of lubricating oil additive and nitrogen borate ester, which is applied in the field of mechanical friction lubrication, can solve the problems of lubricating oil friction reduction, anti-wear performance decline, low addition amount thermal stability, boron active ingredient loss, etc., to reduce pollution, Simple method and high atom utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

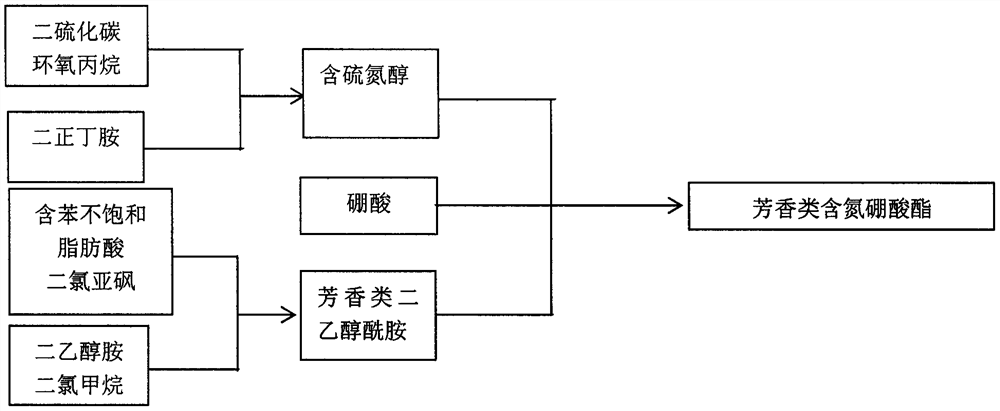

[0025] As another aspect of the present invention, the present invention provides a kind of preparation method of high anti-wear and anti-friction lubricating oil additive, comprising the following steps:

[0026] Preparation of sulfur-nitrogen-containing monoalcohol: adding di-n-butylamine into the reaction vessel, sequentially adding equimolar amounts of carbon disulfide and propylene oxide, and reacting for 1.5 hours to obtain the target compound;

[0027] Preparation of aromatic diethanolamide: add equimolar amounts of aromatic carboxylic acid and thionyl chloride in sequence to the reaction vessel, react for 4 hours, and distill under reduced pressure to remove excess raw materials to obtain aromatic acid chloride intermediates, then add equimolar Amount of diethanolamine, dichloromethane, reacted for 6 hours to obtain the target product;

[0028] Preparation of aromatic nitrogen-containing borates: add equimolar amounts of sulfur-nitrogen-containing monoalcohol, boric ac...

Embodiment 1

[0033] Preparation of high anti-wear and anti-friction lubricating oil additives:

[0034] Add equimolar amounts of benzoic acid and thionyl chloride successively to the reaction vessel, react for 4 hours, and remove excess raw materials by distillation under reduced pressure to obtain benzoyl chloride, then add equimolar amounts of diethanolamine and dichloromethane successively, and react 6 Hour, obtain benzoic acid diethanolamide;

[0035] Di-n-butylamine is added in the reaction vessel, and carbon disulfide and propylene oxide of equimolar amounts are added successively, and reacted for 1.5 hours to obtain sulfur nitrogen-containing monohydric alcohol;

[0036] Add equimolar amounts of sulfur-nitrogen-containing monoalcohol, boric acid and benzoic acid diethanolamide into the reaction vessel, heat and react for 2 hours under the protection of nitrogen, and evaporate the solvent to obtain a yellow oily liquid, which is the aromatic nitrogen-containing borate .

Embodiment 2

[0038] The preparation method is the same as 1, the difference is that benzoic acid is replaced by phenylacetic acid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com