Ultra-long-acting dual modification method for hypereutectic aluminum-silicon alloy

An aluminum-silicon alloy and hypereutectic technology, which is applied in the field of long-term double metamorphism of hypereutectic aluminum-silicon alloy, can solve the problems of general metamorphism, difficulty, and inability to achieve double metamorphism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

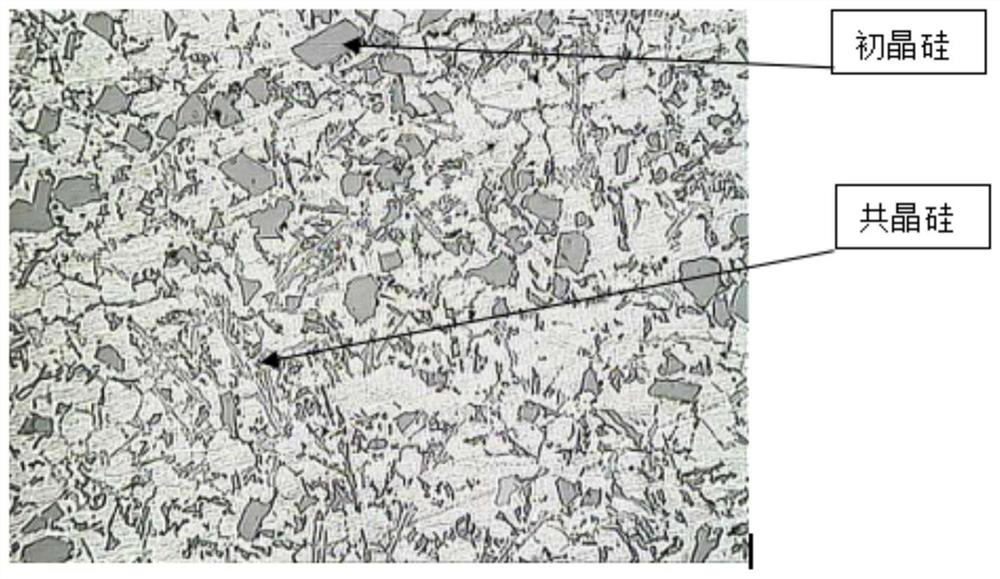

Embodiment 1

[0040] 1) Ingredients:

[0041] A hypereutectic aluminum-silicon alloy ingredients: Weigh 87 kg of A00 aluminum ingot and 13 kg of industrial silicon;

[0042] B prepares the fluorine salt according to the weight of the aluminum-silicon alloy, formula principle: ①Si / Ti+Zr+B+C=2, ②Ti, Zr, B, C molar ratio is Ti:Zr:B:C=1:1:2: 2. Potassium fluotitanate needs to be weighed to be 8.6 kg (according to 98% absorption rate); wherein potassium fluozirconate needs to be weighed to be 10.1 kg (according to 99% absorption rate); potassium fluoborate to be weighed is 8.9 kg (according to 98% absorption rate), weighing graphene is 1.1 kilograms (by 80% absorption rate);

[0043] 2) In situ reaction:

[0044] Put the original aluminum ingots and industrial silicon into the intermediate frequency furnace, start the furnace to heat up, after the aluminum ingots and industrial silicon are completely melted, remove the surface scum, measure the temperature of the aluminum water at 700°C, first...

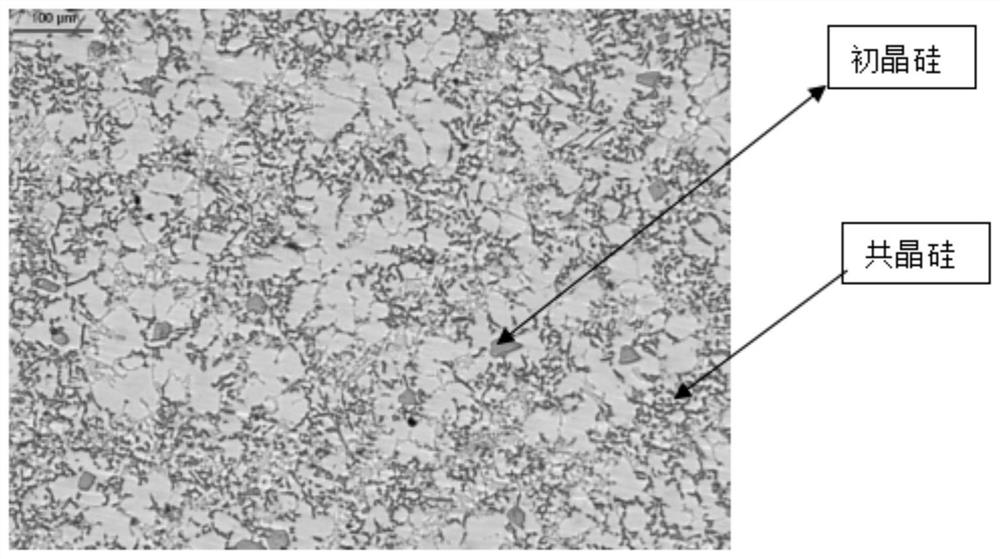

Embodiment 2

[0050] 1) Ingredients:

[0051] A Hypereutectic aluminum-silicon alloy ingredients: Weigh 80 kg of A00 aluminum ingot and 20 kg of industrial silicon;

[0052] B prepares fluorine salt according to the weight of aluminum-silicon alloy, formula principle: ①Si / Ti+Zr+B+C=3.5, ②Ti, Zr, B, C molar ratio is Ti:B:C=1:1:2:2, Potassium fluotitanate which needs to be weighed is 7.6 kilograms (according to 98% absorption rate); wherein needs to weigh potassium fluozirconate to be 8.9 kilograms (according to 99% absorption rate); absorption rate), weighing graphene is 0.93 kilograms (according to 80% absorption rate); 2) in-situ reaction:

[0053] Put the original aluminum ingot and industrial silicon into the intermediate frequency furnace, start the furnace to heat up, after the aluminum ingot and industrial silicon are completely melted, remove the surface scum, control the temperature of the aluminum water to 720°C, first add potassium fluoroborate, and react for 10 minutes; Add the...

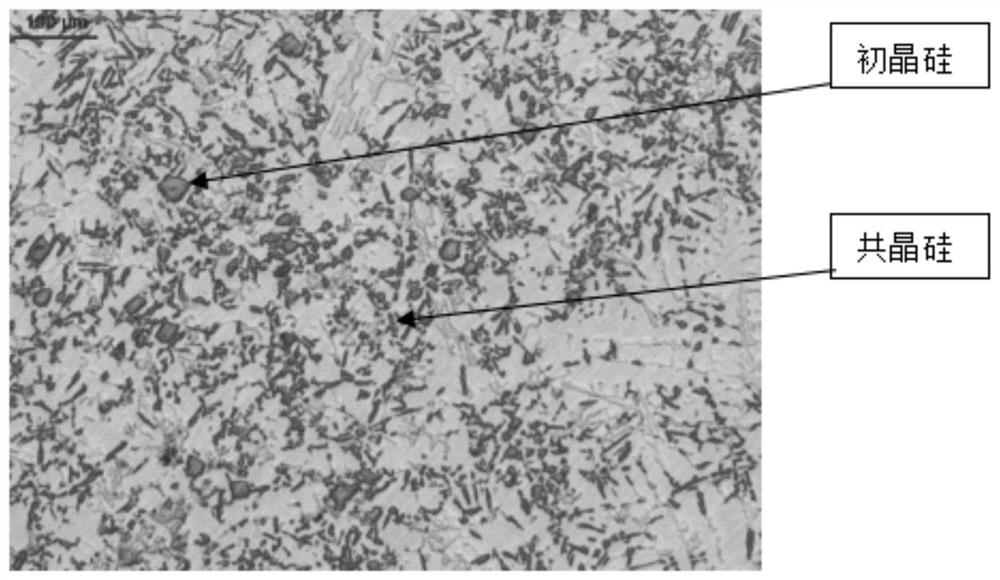

Embodiment 3

[0059] 1) Ingredients:

[0060] A hypereutectic aluminum-silicon alloy ingredients: Weigh 75 kg of A00 aluminum ingot and 25 kg of industrial silicon;

[0061] B prepares fluorine salt according to the weight of aluminum-silicon alloy, formula principle: ①Si / Ti+Zr+B+C=5, ②Ti, Zr, B, C molar ratio is Ti:B:C=1:1:2:2, Potassium fluotitanate which needs to be weighed is 6.6 kilograms (according to 98% absorption rate); wherein needs to weigh potassium fluozirconate to be 7.8 kilograms (according to 99% absorption rate); Absorption rate), weighing graphene is 0.81 kilogram (by 80% absorption rate);

[0062] 2) In situ reaction:

[0063] Put the original aluminum ingot and industrial silicon into the intermediate frequency furnace, start the furnace to heat up, after the aluminum ingot and industrial silicon are completely melted, remove the surface scum, control the temperature of the aluminum water to 750°C, first add potassium fluoroborate, and react for 10 minutes; Add the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com