Method for preparing ceramsite from acidic vanadium extraction tailings

A technology for extracting vanadium tailings and acidity, which is applied in the field of preparation of ceramsite from acidic vanadium extraction tailings, which can solve the problems of complex composition of magnetite tailings, secondary pollution, and many organic components, and achieve good economic benefits and application Foreground, efficient recovery, simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

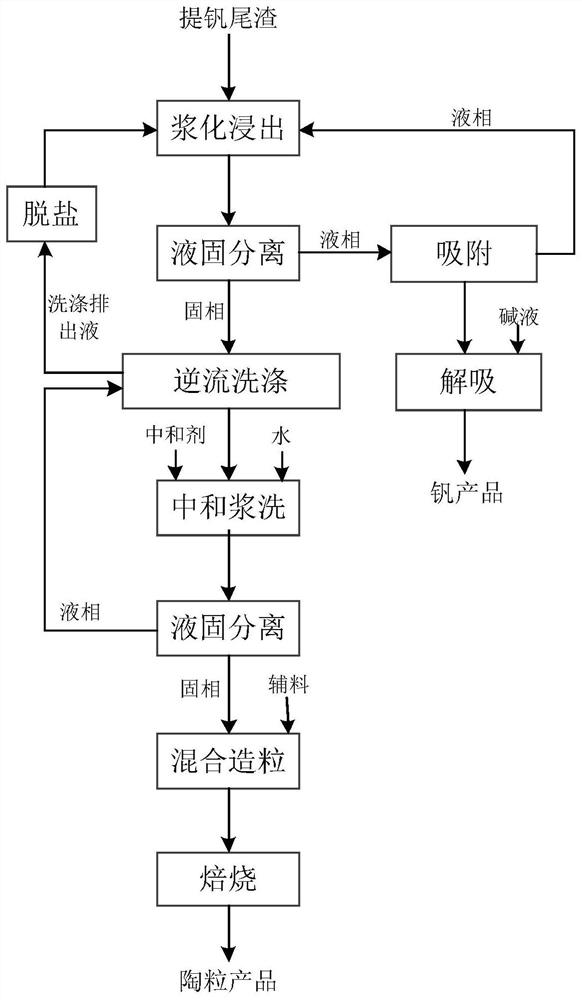

[0062] This embodiment provides a method for preparing ceramsite from acidic vanadium extraction tailings, the process flow chart of the method is as follows figure 1 shown, including the following steps:

[0063] (1) Slurry leaching the acid tailings after vanadium extraction from the stone coal vanadium ore, the pH value of the acid tailings is 0.3, the temperature of the slurry leaching is 25° C., and the time is 3 hours, and the leaching solution and leaching residue are obtained by filtering;

[0064] (2) The leaching solution obtained in step (1) is subjected to adsorption treatment, the temperature of the adsorption treatment is 25° C., the adsorbent used is a cation exchange resin, and the adsorption completion liquid obtained after the adsorption treatment is returned for slurry leaching; the adsorbent completes the adsorption Afterwards, use a concentration of 0.02mol·L -1 The NaOH solution is used for desorption, the adsorbent after desorption is recycled, and the ...

Embodiment 2

[0069] This embodiment provides a method for preparing ceramsite from acidic vanadium extraction tailings, said method comprising the following steps:

[0070] (1) Slurry leaching the acid tailings after vanadium extraction from the stone coal vanadium ore, the pH value of the acid tailings is 1.5, the temperature of the slurry leaching is 45° C., and the time is 4 hours, and the leaching solution and leaching residue are obtained by filtering;

[0071] (2) The leaching solution obtained in step (1) is subjected to adsorption treatment, the temperature of the adsorption treatment is 35° C., the adsorbent used is a cation exchange resin, and the adsorption completion liquid obtained after the adsorption treatment is returned for slurry leaching; the adsorbent completes the adsorption Afterwards, use a concentration of 0.03mol·L -1 The KOH solution is used for desorption, the adsorbent after desorption is recycled, and the solution after desorption is used to prepare vanadium pr...

Embodiment 3

[0076] This embodiment provides a method for preparing ceramsite from acidic vanadium extraction tailings, said method comprising the following steps:

[0077] (1) Slurry leaching the acid tailings after vanadium extraction from the stone coal vanadium ore, the pH value of the acid tailings is 2.8, the temperature of slurry leaching is 55° C., and the time is 6 hours, and the leachate and leaching residue are obtained by filtering;

[0078] (2) The leaching solution obtained in step (1) is subjected to adsorption treatment, the temperature of the adsorption treatment is 45° C., the adsorbent used is a chelating resin, and the adsorption completion liquid obtained after the adsorption treatment is returned for slurry leaching; the adsorbent completes the adsorption Afterwards, use a concentration of 0.05mol·L -1 The ammonia solution is desorbed, the desorbed adsorbent is recycled, and the desorbed solution is used to prepare vanadium products;

[0079] (3) Perform 5-stage coun...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| cylinder compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com