Preparation process of gel lithium battery

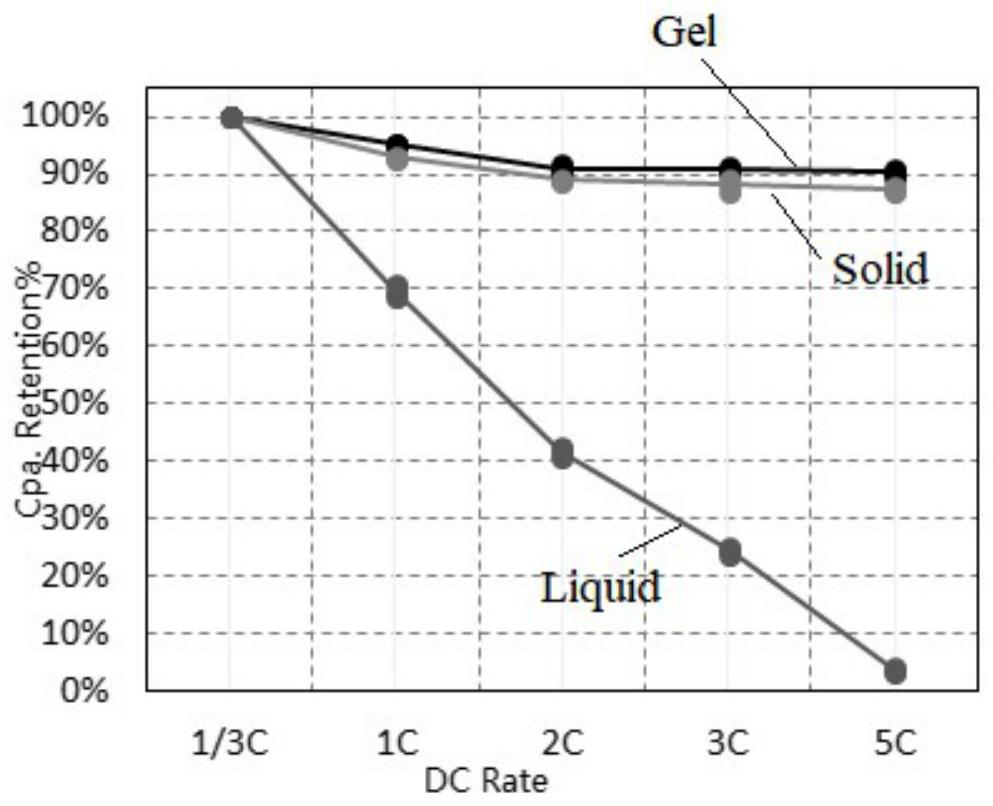

A preparation process, lithium battery technology, applied in secondary batteries, sustainable manufacturing/processing, secondary battery repair/maintenance, etc. Safety factor and energy density, saving space and cost, improving safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

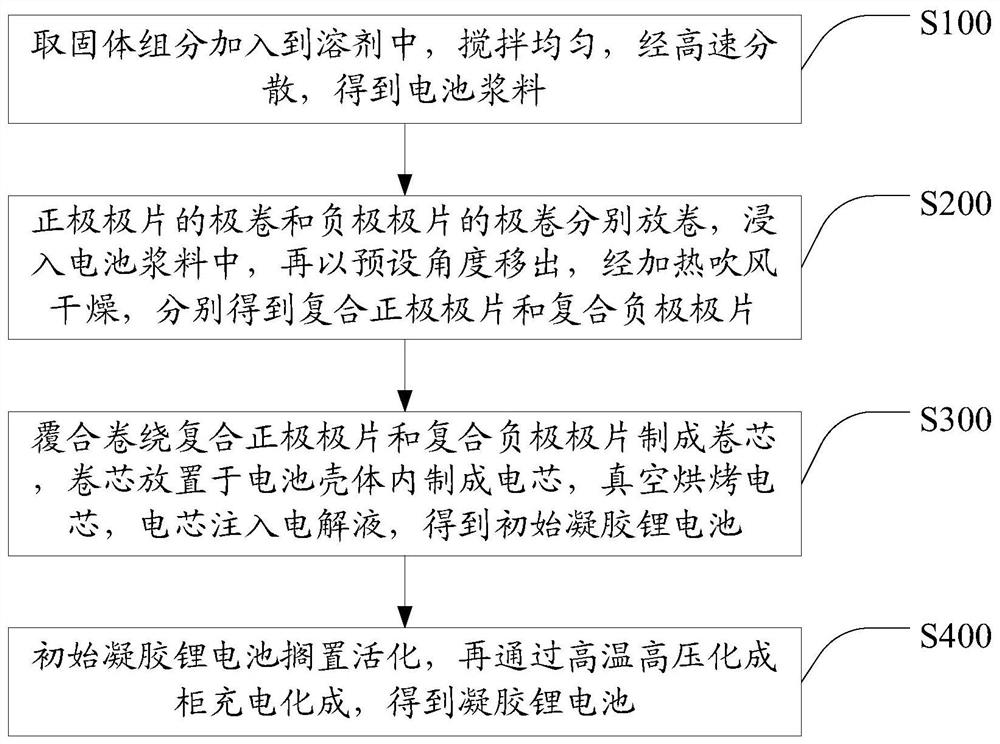

[0046] An embodiment of the present invention provides a preparation process for a gel lithium battery, comprising the following steps:

[0047] S100: By weight percentage, take 84.5% hexafluoropropylene-polyvinylidene fluoride copolymer, 5% cyclophosphazene derivative Add 10% aluminum oxide with a particle size of 10nm and 0.5% polyvinylpyrrolidone into a mixed solvent composed of 85% N-methylpyrrolidone, 10% acetone and 5% isopropanol, stir evenly at 45°C, and Disperse for 6 hrs to obtain a slurry. The solid component of the slurry accounts for 15%, and the solvent accounts for 85%.

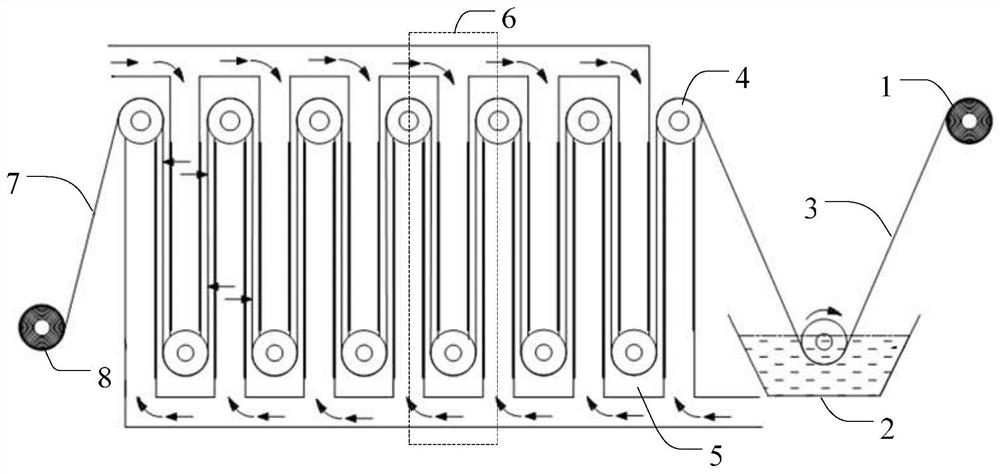

[0048] S200: The pole rolls of the positive pole piece and the pole roll of the negative pole piece are respectively unwound at 6m / min, immersed in the slurry at 60°, and the surface of the other pole piece is coated with slurry coating, and then removed at 60°, and the coating is controlled. The thickness of the layer is 10 μm, and it is dried by gradient heating and blowing at 40°C, 50°C, 6...

Embodiment 2

[0052] An embodiment of the present invention provides a preparation process for a gel lithium battery, comprising the following steps:

[0053] S100: By weight percentage, take 84% hexafluoropropylene-polyvinylidene fluoride copolymer, 5% cyclophosphazene derivative Add 10% aluminum oxide with a particle size of 50nm and 1% polyvinylpyrrolidone to a mixed solvent composed of 85% N-methylpyrrolidone, 10% acetone and 5% isopropanol, stir evenly at 45°C, and Disperse for 6 hrs to obtain a slurry. The solid component of the slurry accounts for 1%, and the solvent accounts for 99%.

[0054] S200: The pole rolls of the positive pole piece and the pole roll of the negative pole piece are respectively unwound at 1m / min, immersed in the slurry at 10°, and the surface of the other pole piece is coated with slurry coating, and then removed at 10°, and the coating is controlled. The thickness of the layer is 2 μm, and it is dried by gradient heating and blowing at 10°C, 20°C, 30°C, 40°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com