Forming method of liquid crystal polymer film and film blowing equipment

A liquid crystal polymer and molding method technology, applied in the field of polymer film processing, can solve the problems of low peel strength and delamination, achieve controllable crystallization and solidification, significant technological progress, and weaken the effect of delamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

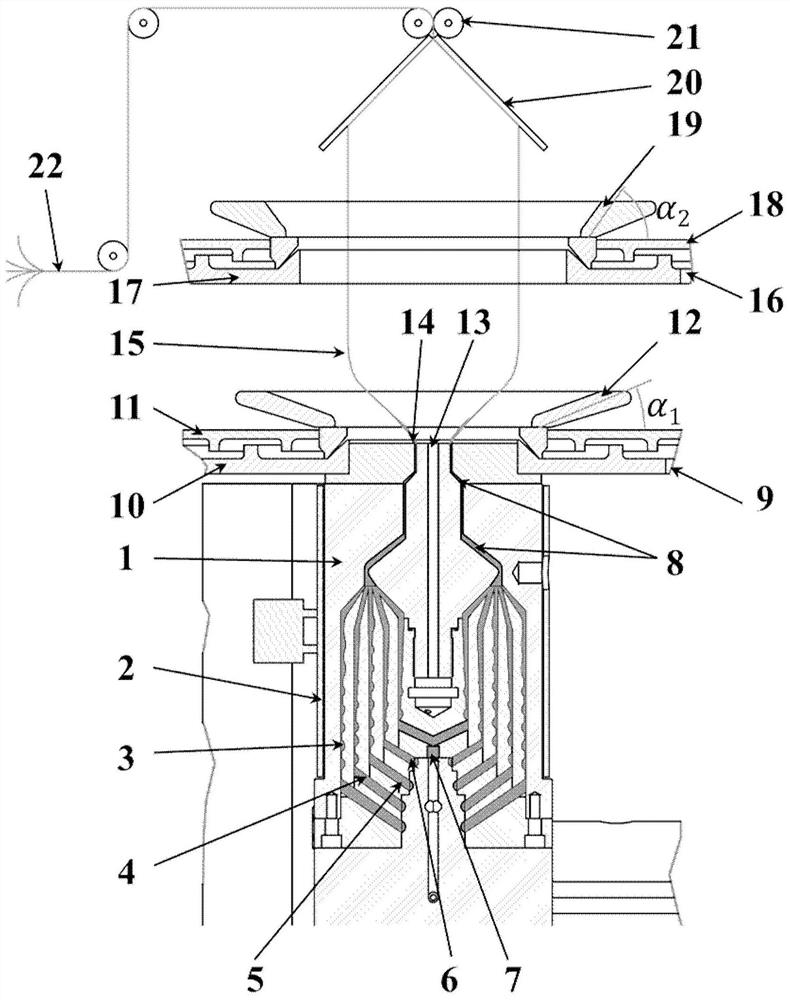

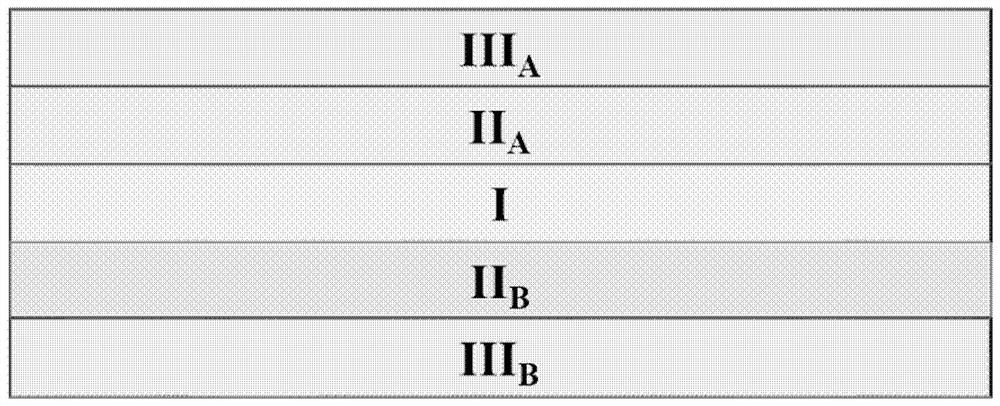

[0080] A single-layer liquid crystal polymer film with an adhesive layer is prepared by using a method for forming a liquid crystal polymer film and a film blowing device provided in the above-mentioned specific embodiments. The structural combination of the multi-layer co-extruded composite film is: III A (polyethylene) / II A (Binder) / I (Liquid Crystal Polymer) / II B (adhesive) / III B (Polyethylene); the liquid crystal polymer material is a liquid crystal copolyester of p-hydroxybenzoic acid and 2-hydroxy-6-naphthoic acid, the melting point is 260°C, and the crystallization temperature is T c The temperature is 215°C, the adhesive material is ethylene / vinyl acetate copolymer, the melting point is 95°C, and the polyethylene is low-density polyethylene containing 1% opening agent, and the melting point is 112°C; The drying pretreatment was carried out in a drying oven, the drying temperature was 130°C, and the drying time was 5 hours. The pretreated liquid crystal polymer mate...

Embodiment 2

[0082] The multi-layer liquid crystal polymer film is prepared by using a method for forming a liquid crystal polymer film and a film blowing device provided in the above-mentioned specific embodiments. The difference between this embodiment and Embodiment 1 is that the extrusion pressure range is 0.1~ 2.5MPa, the air outlet temperature of the first air ring is 200°C, the air outlet temperature of the second air ring is 50°C, the inflation ratio of the film bubble is 1.2, and the total thickness is about 90μm. The tensile strength of the film along the pulling direction is 327MPa, the elongation at break is 21%, the tensile strength perpendicular to the pulling direction is 189MPa, and the elongation at break is 25%, indicating that the obtained liquid crystal polymer film has excellent mechanical properties.

Embodiment 3

[0084] A method for forming a liquid crystal polymer film and a film blowing device provided in the above-mentioned specific embodiments are used to prepare a multilayer liquid crystal polymer film. The difference between this embodiment and Embodiment 1 is that the inflation ratio of the film bubble is 8. Finally, a liquid crystal polymer film with a total thickness of about 35 μm with adhesive layers on both sides is obtained. The tensile strength of the film along the pulling direction is 227 MPa, the elongation at break is 36%, and the tensile strength perpendicular to the pulling direction is 219 MPa. , the elongation at break is 35%, indicating that the obtained liquid crystal polymer film has excellent mechanical properties.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Crystallization temperature | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com