A kind of method for aerobic-anaerobic two-step fermentation treatment of diseased animal wastewater

A disease and animal technology, applied in the field of diseased animal wastewater treatment, can solve the problems of nutrient loss, high energy consumption, insufficient oxygen supply, etc., and achieve the effects of improving fertilizer efficiency, increasing production, reducing energy consumption and operating costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

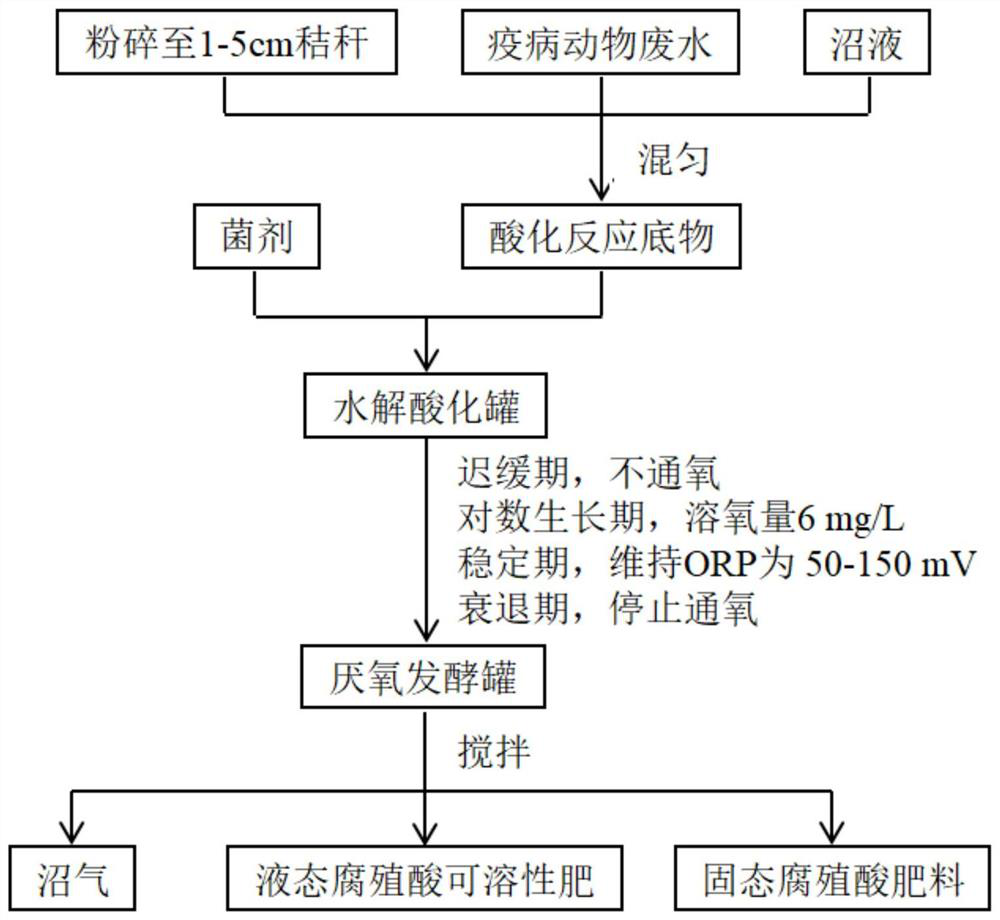

Method used

Image

Examples

Embodiment 1

[0067] A method for aerobic-anaerobic two-step fermentation treatment of diseased animal wastewater, comprising the following steps:

[0068] S1. Mix the diseased animal waste water, crushed straw and filtered biogas slurry (TS is about 1%) according to the mass ratio of 5.6:1:5.6. The mixed liquid has a TS of 8.3% and a carbon-nitrogen ratio of 22:1. , the mixed solution was placed at room temperature for 2-3d, and the pH was adjusted to 7.0-7.5 to obtain the acidification reaction complete slurry substrate;

[0069] S2, the acidification reaction whole slurry substrate is introduced into the hydrolysis acidification tank, and the Bacillus subtilis whose mass is 5% of the total mass of the acidification reaction whole slurry substrate is added, and the dissolved oxygen is regulated in stages, at a temperature of 37±1° C. Carry out aerobic acidification under the condition; Described step-by-step regulation and control of dissolved oxygen amount is:

[0070] Within 0-4h, do not...

Embodiment 2

[0079] The difference between Example 2 and Example 1 is that in step S1, the diseased animal wastewater, crushed straw and filtered biogas slurry (TS is 1%) are uniformly mixed in a mass ratio of 4.2:1:4.2. The TS is 11%, the carbon-nitrogen ratio is 30:1, the mixed solution is placed at room temperature for 2-3 d, and the pH is adjusted to 7.0-7.5 to obtain the acidification reaction complete slurry substrate.

[0080] After aerobic acidification and hydrolysis, the pH of the feed liquid is 4.5-6, the content of volatile acid is 8000-9000 mg / L, and the percentage content of acetic acid reaches 50%-55%.

[0081] After the anaerobic fermentation is completed, the methane content in the produced biogas is above 55%, and the methane production of VS reaches 230mLCH 4 / gVS.

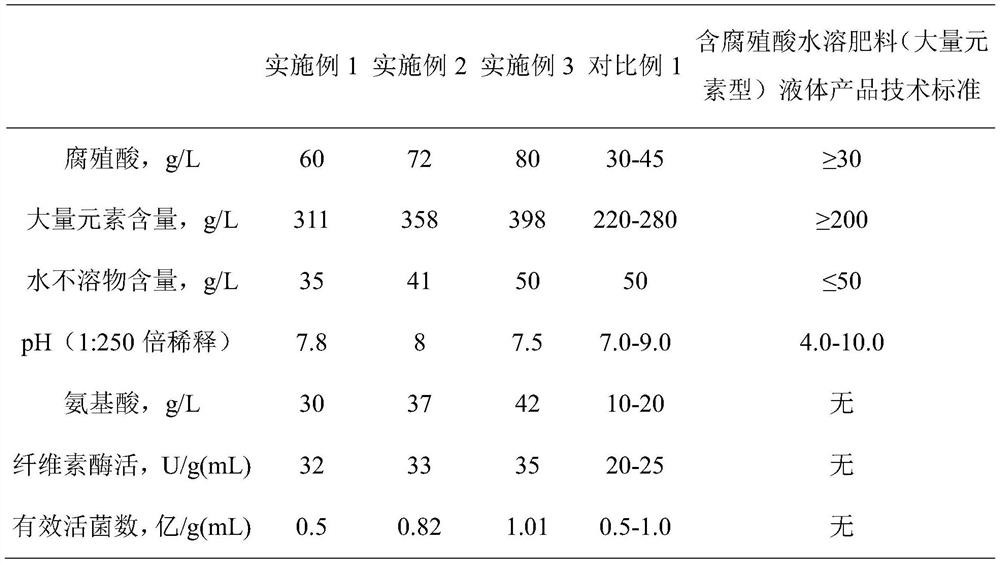

[0082] The properties of the liquid humic acid fertilizer obtained in this example are shown in Table 1.

Embodiment 3

[0084] The difference between Example 3 and Example 1 is that in step S1, the diseased animal wastewater, crushed straw and filtered biogas slurry (TS is 1%) are uniformly mixed in a mass ratio of 3.4:1:3.4, and the mixed solution is The TS is 12.4%, the carbon-nitrogen ratio is 34:1, the mixed solution is placed at room temperature for 2-3 d, and the pH is adjusted to 7.0-7.5 to obtain the acidification reaction full slurry substrate.

[0085] After aerobic acidification and hydrolysis, the pH of the feed liquid is 4-6, the content of volatile acid is 9000-10000 mg / L, and the percentage content of acetic acid reaches 55%-60%.

[0086] After the anaerobic fermentation is completed, the methane content in the produced biogas is above 55%, and the methane production of VS reaches 250mLCH 4 / gVS.

[0087] The properties of the liquid humic acid fertilizer obtained in this example are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com