Preparation method of boehmite with low water absorption

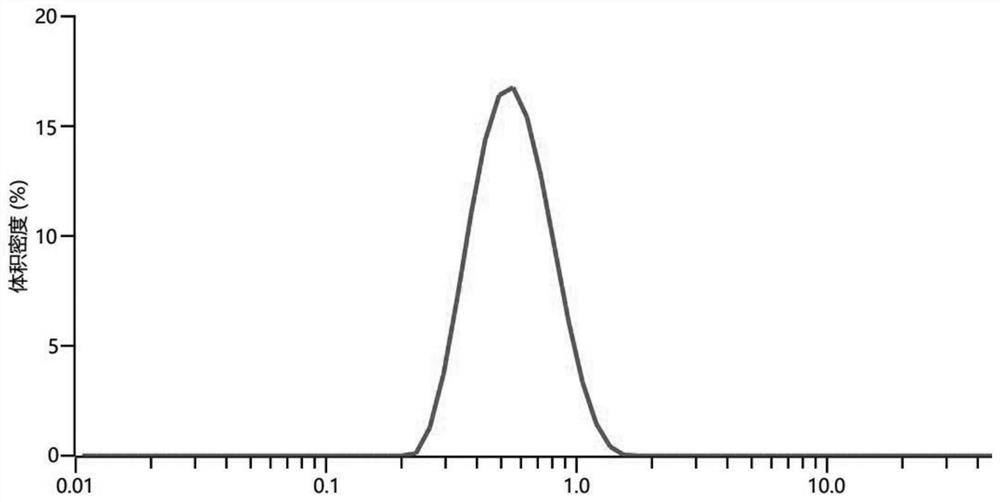

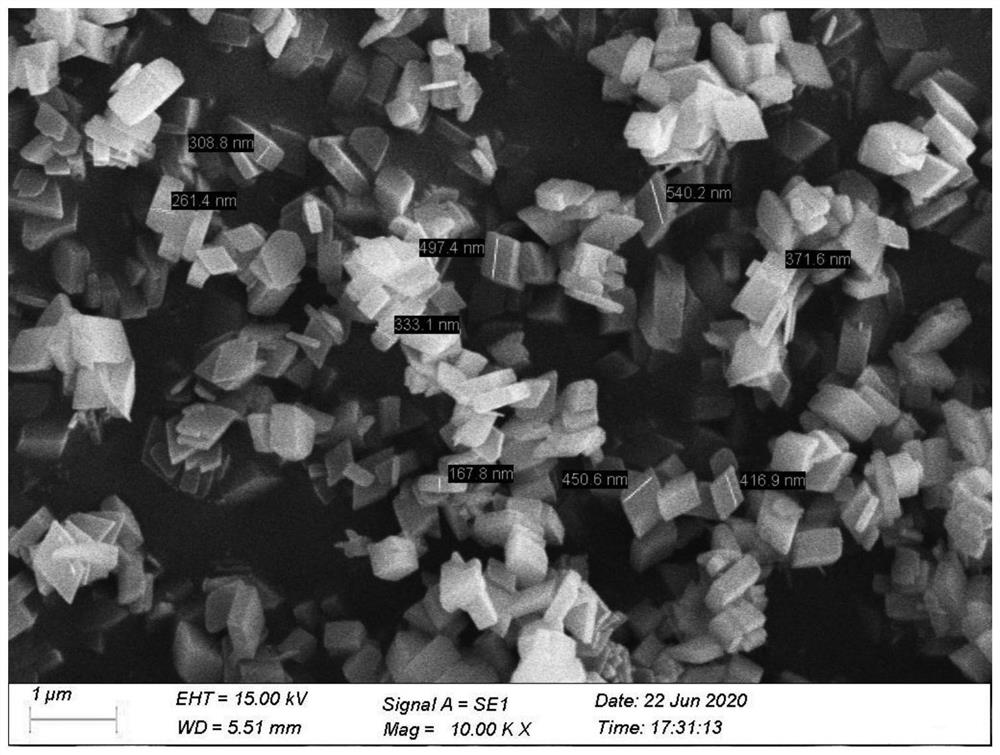

A technology of low water absorption and boehmite, which is applied in the field of preparation of low water absorption boehmite, can solve problems such as high moisture content of coated and rolled products, increase of metal ion impurity content, increase of difficulty of water washing, etc., to achieve Facilitate large-scale industrial production, narrow particle size distribution and uniform shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Step 1: Mix aluminum hydroxide and water according to the mass ratio of 2:3 and stir evenly to obtain a mixed solution A;

[0041] Step 2: Weigh the aluminum hydroxide and the capping agent at a ratio of 1:0.02 to weigh the capping agent, and then add the capping agent to the mixed solution A to obtain a mixed solution B, wherein the capping agent is ammonium polycarboxylate;

[0042] Step 3: Sanding the mixed solution B to obtain a slurry C with a median particle size of 0.4-0.5 μm;

[0043] Step 4: Dilute slurry C and pure water at a ratio of 1:7 to obtain slurry D;

[0044] Step 5: Then add the slurry D into the reactor, and the filling volume of the reactor is 80%; under the condition of 220°C, set the rotation speed at 10rpm / min to carry out the hydrothermal reaction for 4h;

[0045] Step 6: After the hydrothermal reaction is over, the reaction kettle is cooled to room temperature and taken out, filtered, washed and dried with a plate frame, and finally dispersed ...

Embodiment 2

[0047] Step 1: Mix aluminum hydroxide and water according to the mass ratio of 2:3 and stir evenly to obtain a mixed solution A;

[0048] Step 2: Weigh the aluminum hydroxide and the capping agent at a ratio of 1:0.01 to weigh the capping agent, and then add the capping agent to the mixed solution A to obtain a mixed solution B, wherein the capping agent is ammonium polycarboxylate;

[0049] Step 3: Sanding the mixed solution B to obtain a slurry C with a median particle size of 0.4-0.6 μm;

[0050] Step 4: Dilute slurry C and pure water at a ratio of 1:1 to obtain slurry D;

[0051] Step 5: Then add the slurry D into the reactor, and the filling volume of the reactor is 80%; under the condition of 220°C, set the rotation speed at 10rpm / min to carry out the hydrothermal reaction for 4h;

[0052] Step 6: After the hydrothermal reaction is over, the reaction kettle is cooled to room temperature and taken out, filtered, washed and dried with a plate frame, and finally dispersed ...

Embodiment 3

[0054] Step 1: Mix aluminum hydroxide and water according to the mass ratio of 2:3 and stir evenly to obtain a mixed solution A;

[0055] Step 2: Weigh the aluminum hydroxide and the capping agent at a ratio of 1:0.02 to weigh the capping agent, and then add the capping agent to the mixed solution A to obtain a mixed solution B, wherein the capping agent is ammonium polycarboxylate;

[0056] Step 3: Sanding the mixed solution B to obtain a slurry C with a median particle size of 0.4-0.6 μm;

[0057] Step 4: Dilute slurry C and pure water at a ratio of 1:1 to obtain slurry D;

[0058] Step 5: Then add the slurry D into the reactor, and the filling volume of the reactor is 80%; under the condition of 220°C, set the rotation speed at 10rpm / min to carry out the hydrothermal reaction for 4h;

[0059] Step 6: After the hydrothermal reaction is over, the reaction kettle is cooled to room temperature and taken out, filtered, washed and dried with a plate frame, and finally dispersed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Median particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Median particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com