Metal accelerated explosive and preparation method thereof

An explosive and metal technology, applied in the field of metal accelerated explosive and its preparation, can solve problems such as insufficient metal driving ability, and achieve the effects of promoting energy improvement, improving overall speed, and improving metal acceleration ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] This embodiment is carried out with reference to the following composition by mass: 3,4-dinitrofurazanylfuroxan (DNTF) 80%, nano-aluminum powder 15%, ethylene-vinyl acetate copolymer 2%, paraffin 3%.

[0018] The preparation method of this example is as follows:

[0019] (1) Preparation of DNTF / nano-aluminum powder composite particles: Weigh 80g of 3,4-dinitrofurazanylfuroxan and add it into 300ml of dimethyl sulfoxide, stir and dissolve to form 3,4-dinitrofurazanylfuroxan Our dimethyl sulfoxide solution, set aside; Weigh 15g of nano-aluminum powder and add it to the above solution, with a mechanical stirring speed of 200-250r / min, and continue to stir to form a nano-aluminum powder in the 3,4-dinitrofurazanyl oxidation Suspension in furazan dimethyl sulfoxide solution; keep the stirring speed, use the dropping funnel to drop absolute ethanol into the 3,4-dinitrate of the above-mentioned nano-aluminum powder at a speed of 5ml / min~8ml / min In the suspension of furazanyl ...

Embodiment 2

[0023] This embodiment is carried out with reference to the following mass percentage composition: 75% of 3,4-dinitrofurazanyl oxide furazan, 20% of nano-aluminum powder, 2% of ethylene-vinyl acetate copolymer, and 3% of paraffin wax. The preparation method refers to Example 1.

Embodiment 3

[0025]This embodiment is carried out with reference to the following mass percentage composition: 83% of 3,4-dinitrofurazanylfuroxan, 15% of nano-aluminum powder, 1% of ethylene-vinyl acetate copolymer, and 1% of paraffin wax. The preparation method refers to Example 1.

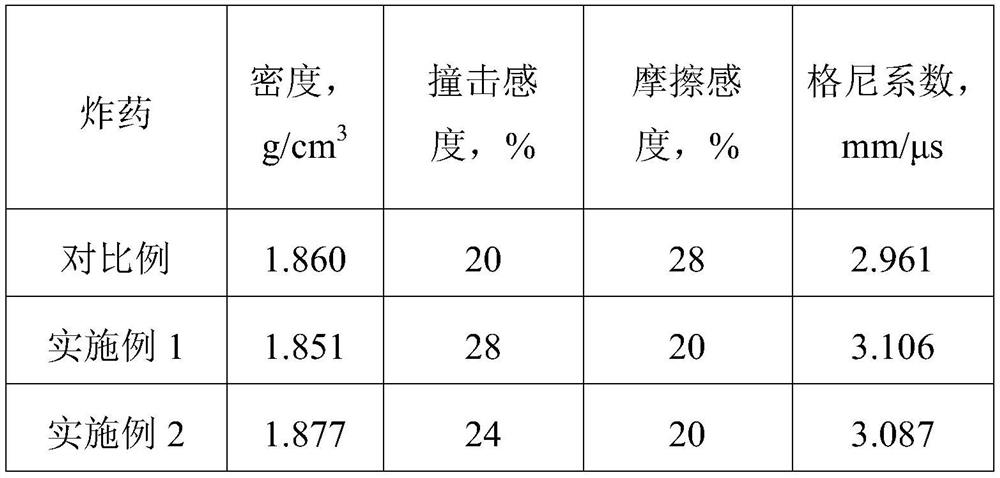

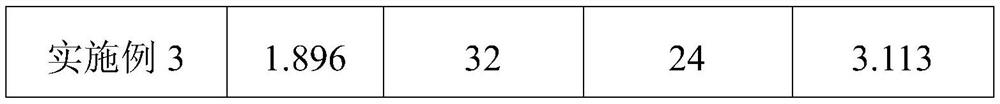

[0026] The performance comparison of each formula of table 1

[0027]

[0028]

[0029] It can be seen from the above table that compared with the comparative example, the charge density of the present application is equivalent or increased, the safety performance is good, and the Gurney coefficient representing the metal acceleration ability is significantly improved, and the maximum increase can be 5.13%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com