A kind of water-based ceramic ink for inkjet printing and its preparation method and application

A ceramic ink and inkjet printing technology, which is applied in application, printing device, ink, etc., can solve the problems that restrict the sustainable development of the ceramic surface decoration industry, and achieve good application prospects, good grinding and dispersion, and good color development performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

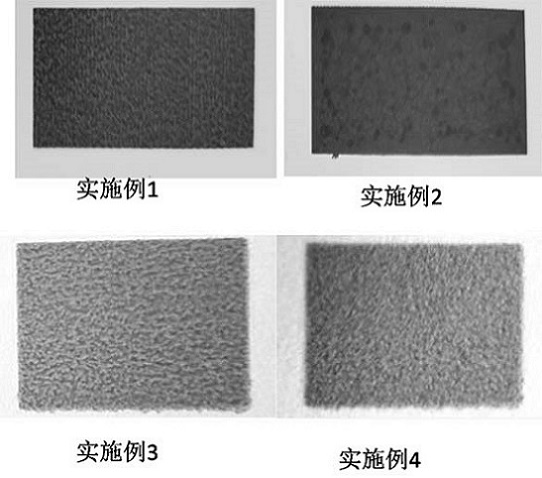

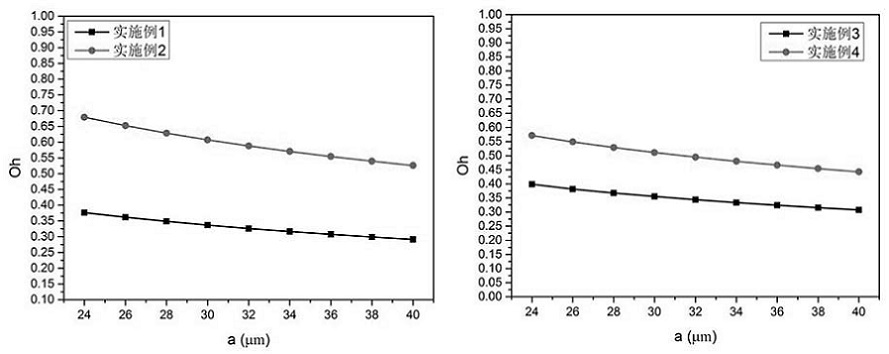

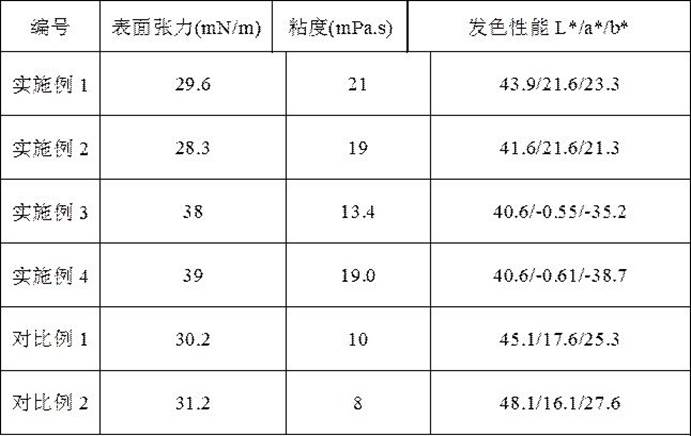

Embodiment 1

[0030] A water-based ceramic ink for inkjet printing in this embodiment comprises the following raw materials in parts by weight: 35 parts of ceramic colorant particles, 10 parts of dispersant, 0.5 part of wetting agent, 2 parts of resin, 0.5 part of anti-sedimentation agent and solvent 52 copies.

[0031] Wherein, the ceramic pigment particles are reddish-brown ceramic pigment particles, specifically ZnFe 1.2 Cr 0.8 o 4 particles.

[0032] Wherein, the solvent is composed of deionized water, diethylene glycol and diethylene glycol monobutyl ether in a mass ratio of 20:30:2.

[0033] Wherein, the dispersant is a polyacrylic dispersant, and the preparation method of the polyacrylic dispersant is as follows: 10 parts of methyl methacrylate, 20 parts of methacrylic acid, 35 parts of 2-acrylamide-2-methylpropane Add sulfonic acid and 15 parts of glycerol monomethacrylate into the round bottom flask in turn, then add 35 parts of deionized water, 1 part of thioglycolic acid and ...

Embodiment 2

[0040] A water-based ceramic ink for inkjet printing in this embodiment comprises the following raw materials in parts by weight: 32 parts of ceramic colorant particles, 8 parts of dispersant, 0.6 part of wetting agent, 1 part of resin, 0.6 part of anti-sedimentation agent and solvent 57 copies.

[0041] Wherein, the ceramic pigment particles are reddish-brown ceramic pigment particles, specifically ZnFe 1.2 Cr 0.8 o 4 particles.

[0042] Wherein, the solvent is composed of deionized water and 1,2-propanediol in a mass ratio of 25:32.

[0043]Wherein, the dispersant is a polyacrylic dispersant, and the preparation method of the polyacrylic dispersant is as follows: 11 parts of methyl methacrylate, 22 parts of methacrylic acid, 37 parts of 2-acrylamido-2-methylpropane Add sulfonic acid and 16 parts of glycerin monomethacrylate into the round bottom flask in turn, then add 38 parts of deionized water, 2 parts of thioglycolic acid and 1 part of potassium persulfate, then heat...

Embodiment 3

[0050] A water-based ceramic ink for inkjet printing in this embodiment comprises the following raw materials in parts by weight: 35 parts of ceramic colorant particles, 10 parts of dispersant, 0.5 part of wetting agent, 2 parts of resin, 0.5 part of anti-sedimentation agent and solvent 52 copies.

[0051] Wherein, the ceramic pigment particles are blue ceramic pigment particles, specifically CoAl 2 o 4 particles.

[0052] Wherein, the solvent is composed of deionized water, diethylene glycol and diethylene glycol monobutyl ether in a mass ratio of 20:30:2.

[0053] Wherein, the dispersant is a polyacrylic dispersant, and the preparation method of the polyacrylic dispersant is as follows: 12 parts of methyl methacrylate, 25 parts of methacrylic acid, 38 parts of 2-acrylamide-2-methylpropane Add sulfonic acid and 16 parts of glycerol monomethacrylate into the round bottom flask in turn, then add 42 parts of deionized water, 1.5 parts of thioglycolic acid and 1.5 parts of pot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com