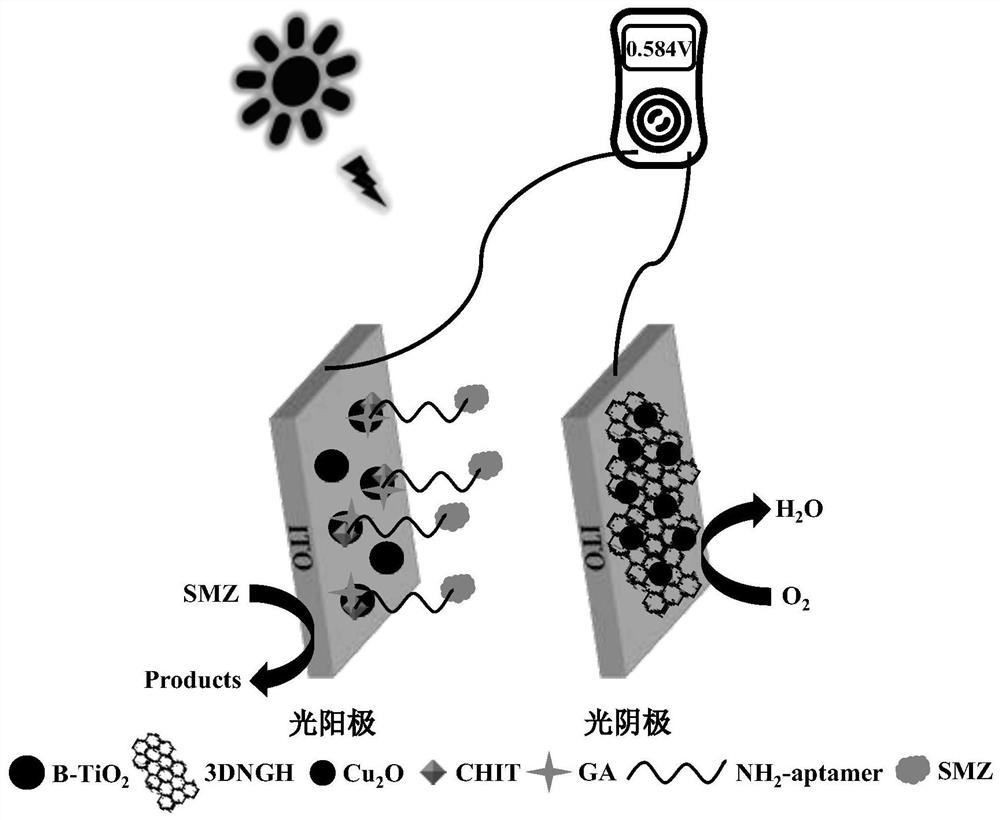

Construction method of novel photo-assisted bipolar self-energized aptamer sensing device

An aptamer sensor and construction method technology, applied in the field of electrochemical biosensing, can solve problems such as threats to human health, labor-intensive, and complex operations, and achieve excellent power output performance, improved utilization, and good energy level matching. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

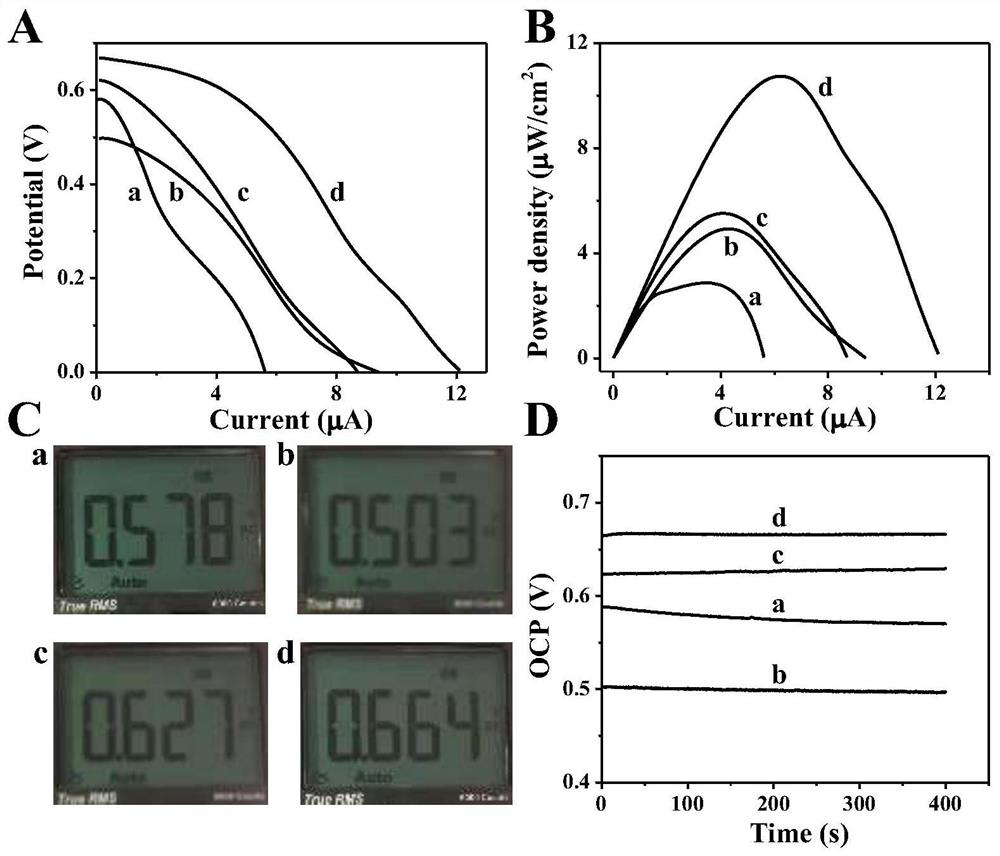

Examples

Embodiment 1

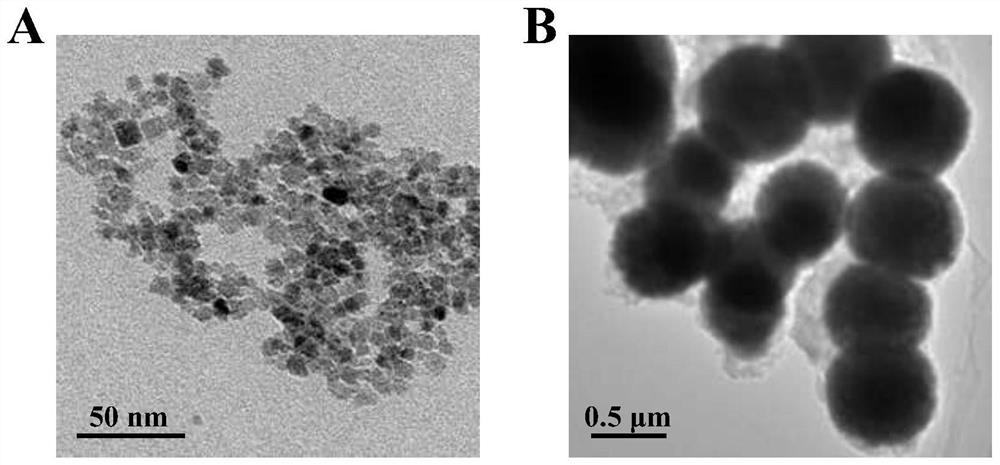

[0050] (1) B-TiO 2 preparation of

[0051] Measure 1.7mL of tetrabutyl titanate and 2.5mL of ethanol and mix them evenly to obtain solution A; measure and mix 0.1mL of concentrated nitric acid, 2.5mL of ethanol and 0.5mL of water to obtain solution B; Add dropwise into solution B, stir for 0.5h to obtain mixed solution C, transfer it to a stainless steel autoclave, and react at 180°C for 12h to obtain solid product titanium dioxide; weigh 200mg of titanium dioxide and 66.66mg of sodium borohydride and mix them in a mortar Grind well, transfer to a porcelain crucible, put into a tube furnace, and calcinate at 350°C for 1h in an argon atmosphere with a heating rate of 10°C / min to obtain B-TiO 2 nanoparticles.

[0052] (2)Cu 2 Preparation of O / 3DNGH

[0053] First, 50 mL of graphene oxide dispersion (1 g / mL) was stirred with 2 g of urea, transferred to an autoclave, and reacted at 180 ° C for 12 h to obtain 3DNGH. Then, dissolve 0.25g of copper nitrate in 50mL of water, drop...

Embodiment 2

[0067] (1) B-TiO 2 Preparation of nanoparticles

[0068] Measure 1mL of tetrabutyl titanate and 1.5mL of ethanol and mix them evenly to obtain solution A; measure and mix 0.05mL of concentrated nitric acid, 1.25mL of ethanol and 0.25mL of water to obtain solution B; Add to solution B, stir for 0.5h to obtain mixed solution C, transfer to a stainless steel autoclave, react at 180°C for 10h, and obtain solid product titanium dioxide; weigh 100mg of titanium dioxide and mix with 33.33mg of sodium borohydride, grind in a mortar fully, transferred to a porcelain crucible, placed in a tube furnace, and calcined at 300°C for 1h in an argon atmosphere with a heating rate of 10°C / min to obtain B-TiO 2 nanoparticles.

[0069] (2)Cu 2 Preparation of O / 3DNGH

[0070] First, 50 mL of graphene oxide dispersion (1 g / mL) was stirred with 2 g of urea, transferred to an autoclave, and reacted at 180 ° C for 12 h to obtain 3DNGH. Then, dissolve 0.25g of copper nitrate in 50mL of water, drop...

Embodiment 3

[0073] (1) B-TiO 2 Preparation of nanoparticles

[0074] Measure 3mL of tetrabutyl titanate and 4mL of ethanol and mix them evenly to obtain solution A; measure and mix 0.15mL of concentrated nitric acid, 3.75mL of ethanol and 0.75mL of water to obtain solution B; add solution A dropwise into solution B, stirred for 0.5h to obtain mixed solution C, transferred to a stainless steel autoclave, and reacted at 180°C for 14h to obtain a solid product of titanium dioxide; weigh 300mg of titanium dioxide and 100mg of sodium borohydride, mix them in a mortar and grind them thoroughly, Transfer to a porcelain crucible, put it into a tube furnace, and calcinate at 400 °C for 1 h in an argon atmosphere with a heating rate of 10 °C / min to obtain B-TiO 2 nanoparticles.

[0075] (2)Cu 2 Preparation of O / 3DNGH

[0076] First, 50 mL of graphene oxide dispersion (1 g / mL) was stirred with 2 g of urea, transferred to an autoclave, and reacted at 180 ° C for 12 h to obtain 3DNGH. Then, disso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com