Electrolyte and lithium ion battery

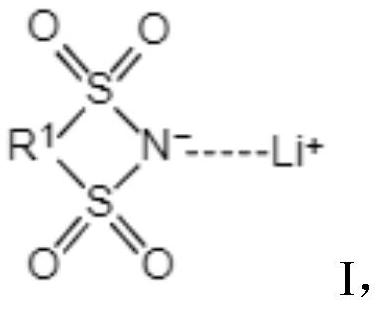

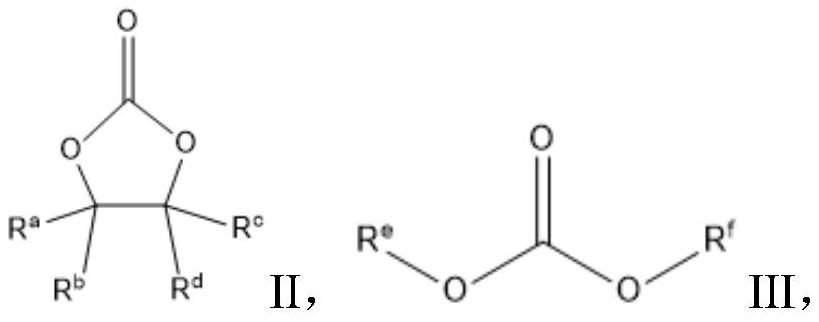

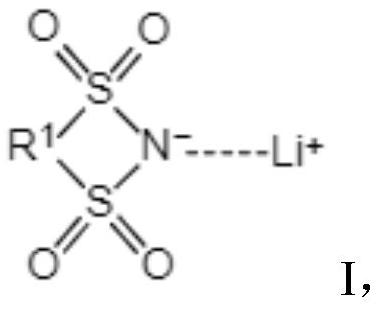

An electrolyte and lithium salt technology, which is applied in the field of electrolyte and lithium-ion batteries, can solve the problems of reduced battery performance, lifespan, and poor stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] Electrolyte preparation

[0059] Under the inert gas (nitrogen) atmosphere that moisture is lower than 5ppm, ethylene carbonate (EC) and ethyl methyl carbonate (EMC) are mixed by mass ratio 3:7 and prepare non-aqueous solvent 1000mL, will Add lithium hexafluorophosphate into the aforementioned non-aqueous solvent and mix evenly, so that the added lithium salt is completely dissolved. Then add vinylene carbonate (VC) and 1,3-propane sultone (PS) and mix well to obtain the electrolyte. In the resulting electrolyte, The mass percentage in the electrolyte is 1.75%, the mass percentage of lithium hexafluorophosphate is 11.25%; the mass percentage of vinylene carbonate (VC) is 1%, 1,3-propane sultone ( The mass percent content of PS) in the electrolyte solution is 1%, and the balance is non-aqueous solvent.

[0060] Li-ion battery preparation

[0061] Preparation of the positive plate

[0062] Mix the positive electrode active material lithium nickel cobalt manganese ox...

Embodiment 2

[0070] Electrolyte preparation

[0071] Under the inert gas (nitrogen) atmosphere that moisture is lower than 5ppm, ethylene carbonate (EC) and ethyl methyl carbonate (EMC) are mixed by mass ratio 3:7 and prepare non-aqueous solvent 1000mL, will Add lithium hexafluorophosphate into the aforementioned non-aqueous solvent and mix evenly, so that the added lithium salt is completely dissolved. Then add vinylene carbonate (VC) and 1,3-propane sultone (PS) and mix well to obtain the electrolyte. In the resulting electrolyte, The mass percentage in the electrolyte is 1.87%, the mass percentage of lithium hexafluorophosphate is 11.25%; the mass percentage of vinylene carbonate (VC) is 1%, 1,3-propane sultone ( The mass percent content of PS) in the electrolyte solution is 1%, and the balance is non-aqueous solvent.

[0072] Li-ion battery preparation

[0073] The method for preparing the lithium-ion battery in Example 1 is roughly the same, except that the electrolyte used in t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com