mo-eu co-doped titanium dioxide/aluminum phosphate molecular sieve composite photocatalyst and its application

An aluminum phosphate molecular sieve, titanium dioxide technology, applied in molecular sieve catalyst, metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, etc., can solve the problem of dye wastewater treatment rate of less than 30%, photogenerated carrier recombination The problem of high rate and qualified rate of less than 60% can achieve the effect of improving catalytic efficiency, improving photocatalytic activity and uniform particle size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

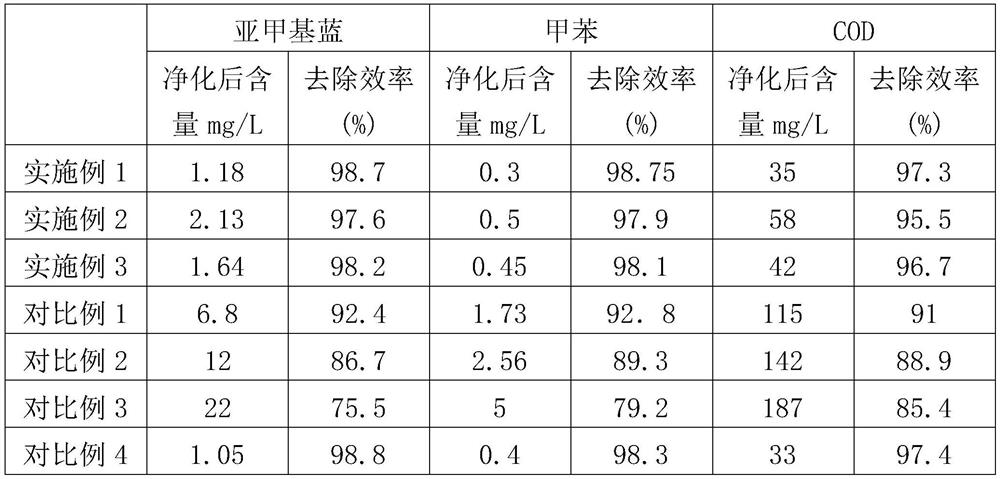

Examples

preparation example Construction

[0030] A Mo-Eu co-doped titanium dioxide / aluminum phosphate molecular sieve composite photocatalyst uses aluminum phosphate molecular sieve as a carrier and Mo-Eu co-doped titanium dioxide nano-microspheres as an active component, and the preparation method thereof comprises the following steps:

[0031] Step S1, preparing the nano-microsphere active component of Mo-Eu co-doped titanium dioxide, which specifically includes the following steps:

[0032] Step S11, mixing 10-20 parts of tetrabutyl orthotitanate and 20-30 parts of absolute ethanol to obtain mixed solution A;

[0033] Step S12, dissolving 5-8 parts of sodium molybdate in water to obtain a sodium molybdate solution;

[0034] Step S13, adding sodium molybdate solution to mixed solution A, and adding 2-3 parts of europium sulfate dropwise under ultrasonic stirring conditions to obtain mixed solution B; wherein the frequency of ultrasonic stirring is 30-35 Hz;

[0035] In step S14, the mixed solution B is centrifuged,...

Embodiment 1

[0046] A Mo-Eu co-doped titanium dioxide / aluminum phosphate molecular sieve composite photocatalyst, the preparation method comprising the following steps:

[0047] Step S1, preparing the nano-microsphere active component of Mo-Eu co-doped titanium dioxide, which specifically includes the following steps:

[0048] Step S11, mixing 10 parts of tetrabutyl orthotitanate and 20 parts of absolute ethanol to obtain mixed solution A;

[0049] Step S12, dissolving 5 parts of sodium molybdate in water to obtain a sodium molybdate solution;

[0050] Step S13, adding sodium molybdate solution to mixed solution A, and adding 2 parts of europium sulfate dropwise under stirring conditions to obtain mixed solution B;

[0051] In step S14, the mixed solution B is centrifuged, and the obtained slurry is vacuum-dried at 50°C for 2-3 hours;

[0052] In step S15, the dried material is calcined, heated to 400°C at a heating rate of 8-10°C / min, and kept for 30-40min; 60 min to obtain the nano-mi...

Embodiment 2

[0060] A Mo-Eu co-doped titanium dioxide / aluminum phosphate molecular sieve composite photocatalyst, the preparation method comprising the following steps:

[0061] Step S1, preparing the nano-microsphere active component of Mo-Eu co-doped titanium dioxide, which specifically includes the following steps:

[0062] Step S11, mixing 20 parts of tetrabutyl orthotitanate and 30 parts of absolute ethanol to obtain mixed solution A;

[0063] Step S12, dissolving 8 parts of sodium molybdate in water to obtain a sodium molybdate solution;

[0064] Step S13, adding sodium molybdate solution to mixed solution A, and adding 3 parts of europium sulfate dropwise under stirring conditions to obtain mixed solution B;

[0065] In step S14, the mixed solution B is centrifuged, and the obtained slurry is vacuum-dried at 60°C for 2-3 hours;

[0066] In step S15, the dried material is calcined, heated to 450°C at a heating rate of 8-10°C / min, and kept for 30-40min; 60 min to obtain the nano-mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| decolorization rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com